-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 15, 2024 03:36 Back to list

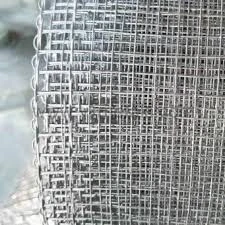

Suppliers of Twisted Soft Annealed Iron Wire for Various Applications

The Importance of Twisted Soft Annealed Iron Wire and Choosing the Right Suppliers

In the world of industrial materials, twisted soft annealed iron wire is a critical product that finds applications in various fields. From construction to manufacturing, this type of wire plays a significant role due to its unique properties, including flexibility, strength, and resistance to corrosion. However, the effectiveness of these applications largely depends on the quality of the wire itself and the reliability of suppliers.

Twisted soft annealed iron wire is created through a process that involves heating the wire to a certain temperature and then cooling it slowly. This method, known as annealing, alters the physical properties of the iron, making it more ductile and easy to work with. Twisting the wire further enhances its structural integrity, providing additional strength and resistance to breakage. These characteristics make the wire an ideal choice for a variety of applications, such as fencing, reinforcement in concrete structures, and even in crafting decorative items.

One of the most essential aspects of utilizing twisted soft annealed iron wire is sourcing it from reputable suppliers. The quality of the wire affects not just the immediate application but also the long-term performance and safety of the projects it is used in. When choosing a supplier, there are several factors to consider

1. Certifications and Compliance Ensure that the supplier adheres to industry standards and regulations. Certifications such as ISO or ASTM can be indicators of a supplier’s commitment to quality and safety.

2. Quality Control A reliable supplier will have rigorous quality control processes in place. This can include inspections, testing of materials, and adherence to specifications. Inquire about their quality assurance practices to ensure you are getting the best product available.

twisted soft annealed iron wire suppliers

3. Material Sourcing Understanding where the iron used for the wire is sourced can also impact quality. Suppliers that utilize high-grade raw materials are more likely to produce a superior product. Transparency in their sourcing practices is a good sign of a reputable supplier.

4. Customer Reviews and Reputation Always look for reviews and testimonials from previous customers. A supplier with a solid reputation backed by positive feedback is likely to be a more reliable choice.

5. Customization Options Depending on your specific needs, you may require twisted soft annealed iron wire in different diameters or tensile strengths. A supplier that can customize their products to meet your requirements is invaluable.

6. Delivery and Logistics The supplier’s ability to deliver on time is crucial for many projects. Delays in material availability can lead to increased costs and project setbacks. Check their logistics capabilities and track record for timely deliveries.

7. Customer Support Lastly, consider the level of customer support offered by potential suppliers. Good communication and support can help resolve any issues that may arise during the purchasing process.

In conclusion, twisted soft annealed iron wire is a versatile and crucial material in various industries, and selecting the right supplier is vital to ensure quality and reliability. By taking into account the factors mentioned above, businesses can make informed decisions and secure the best products for their specific needs. Investing time in finding the right supplier can lead to enhanced safety, improved product performance, and ultimately, the success of the projects that depend on this essential material.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025