-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 23, 2024 11:17 Back to list

Welded Wire Mesh: Types and Benefits

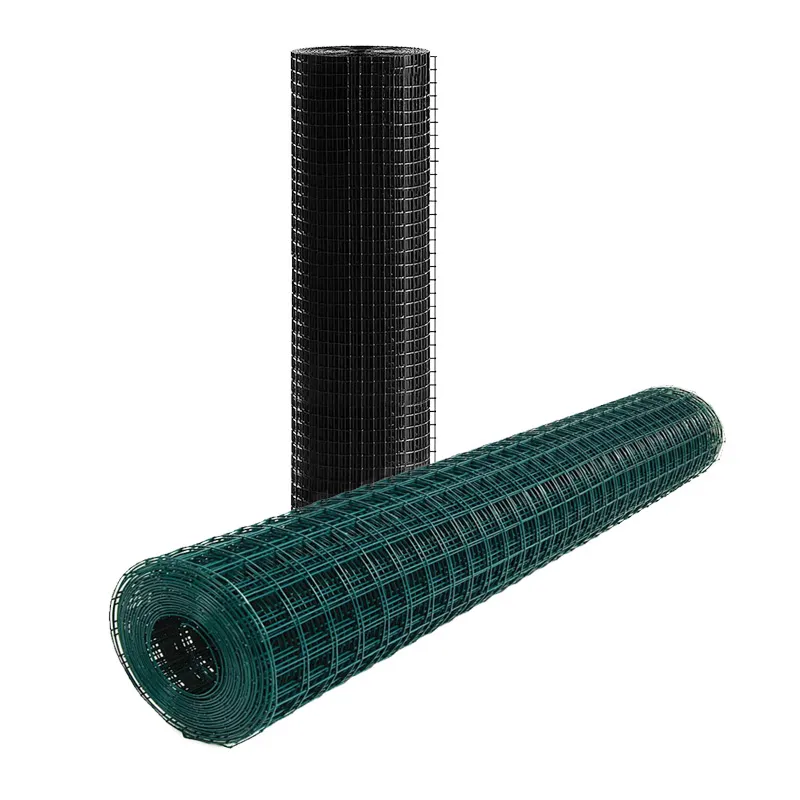

Welded wire mesh is a versatile material used in various applications, from construction and infrastructure to fencing and industrial uses. It is made by welding high-quality low carbon steel wire, ensuring a strong and durable product. The process of welding the wires at their intersections makes welded wire mesh much stronger and more rigid than other types of mesh, such as woven wire mesh.

Depending on the application and environment, welded wire mesh can be coated or treated to enhance its durability and resistance to corrosion. Two common treatments include PVC coating and galvanization (either hot-dipped or electro-galvanized). These treatments provide extra protection against rust, especially in outdoor or harsh environments.

Types of Welded Wire Mesh

PVC Coated Welded Mesh:

In PVC coated welded mesh, the wire is coated with a layer of polyvinyl chloride (PVC) after welding. This coating provides excellent resistance to corrosion, making the mesh suitable for use in harsh environmental conditions, including marine environments, outdoor fencing, and construction. PVC coating also adds aesthetic value by offering color options such as green, black, and white, depending on the application.

Key Benefits:

- Corrosion resistance: Ideal for outdoor use in environments exposed to moisture.

- Aesthetic appeal: Available in various colors to blend into surroundings.

- Durability: Increased lifespan due to the protective PVC layer.

Galvanized Welded Mesh:

Galvanized welded wire mesh is treated with a zinc coating to prevent rust and corrosion. There are two primary types of galvanized welded mesh:

- Hot Dipped Galvanized: The mesh is dipped in molten zinc after welding. This method provides thicker zinc coating, offering greater protection against corrosion and rust. Hot-dipped galvanized meshis ideal for applications exposed to the elements, such as fencing, construction reinforcements, and agriculture.

- Electro Galvanized: A thinner layer of zinc is applied to the mesh through an electroplating process. While electro-galvanized meshprovides some level of corrosion resistance, it is generally less durable than hot-dipped galvanized mesh. It is suitable for indoor use or environments with less exposure to moisture and chemicals.

Key Benefits:

- Rust protection: Zinc coating protects the steel from oxidation.

- Variety of applications: Suitable for use in construction, agriculture, and general industrial applications.

- Cost-effective: Galvanized mesh is a budget-friendly option for many applications.

Manufacturing Process of Welded Wire Mesh

Welded wire mesh is manufactured using automatic equipment to ensure precision and uniformity. The process begins with high-quality iron wire or low carbon steel wire. The wires are positioned in a grid pattern and welded together at each intersection, providing a strong, inflexible structure. After welding, the mesh may be treated with various coatings, such as zinc plating or PVC coating, to enhance its durability.

The zinc plating process can occur after the welding to ensure that the zinc covers both the steel and welded joints, which are otherwise vulnerable to corrosion. This post-welding treatment ensures comprehensive protection, especially in demanding environments.

Applications of Welded Wire Mesh

The versatility of welded wire mesh makes it a popular choice for a variety of applications:

Construction and Infrastructure:

Welded wire mesh is used as reinforcement in concrete structures, particularly in roads, bridges, and buildings. Its strength and rigidity make it ideal for supporting the weight and stress that comes with large-scale construction projects.

Fencing and Enclosures:

Welded mesh is commonly used for security fencing around residential, commercial, and industrial properties. The PVC coated version adds extra durability and visual appeal to fences, making them ideal for parks, gardens, and outdoor areas. Galvanized welded mesh is widely used for fencing in agricultural applications like animal enclosures or crop protection.

Industrial Use:

Welded wire mesh is used in various industrial applications, such as partitions, racks, and protective screens. Its durability and resistance to wear and tear make it suitable for heavy-duty use.

Agriculture:

In agriculture, welded mesh is often used to construct enclosures for animals, poultry cages, and crop support structures. The galvanized mesh option ensures that the mesh remains rust-free even in outdoor, moist conditions.

Decorative Applications:

Thanks to its aesthetic potential, especially when PVC coated, welded wire mesh can be used in decorative projects like garden trellises, outdoor furniture, and landscape design.

Welded wire mesh, available in various forms such as PVC coated, hot-dipped galvanized, and electro-galvanized, is a durable and versatile material widely used in construction, fencing, agriculture, and industrial applications. The adoption of high-quality low carbon steel wire and precision automatic equipment ensures that welded wire mesh products deliver strength, longevity, and resistance to harsh environmental conditions.

Contact us today to find the right type of welded wire mesh for your project needs, whether it's for construction, fencing, or industrial use!

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NewsNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NewsNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NewsNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NewsNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NewsNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NewsNov.11,2025