-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 14, 2025 10:27 Back to list

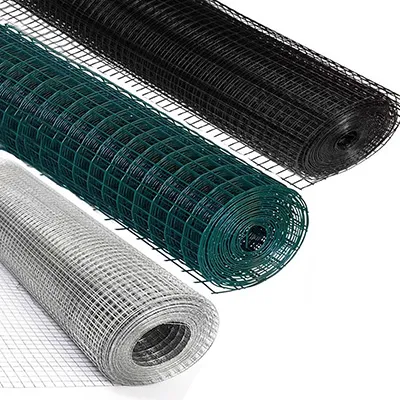

Welded Wire Mesh

PVC welded wire mesh, an innovative solution in the realm of construction and industry, offers durability, versatility, and efficiency unmatched by other materials. Engineers and builders increasingly turn to PVC welded wire mesh for projects requiring robust structural integrity and flexibility.

Experience with PVC welded wire mesh speaks to its ease of installation, maintenance, and adaptability. Due to its lightweight nature, it simplifies the installation process, reducing manual labor and associated costs. Moreover, the low maintenance necessity born from its resilient coating means fewer resources are spent on upkeep, adding to its economic advantages. In environments prone to extreme weather conditions, PVC welded wire mesh has proven to maintain structural integrity better than galvanized steel wire alternatives. For contractors and builders prioritizing environmental sustainability, PVC welded wire mesh offers an eco-friendly option. The materials used in its production can be recycled, and the manufacturing process can be tailored to reduce environmental impact, addressing both industry and consumer demand for greener building solutions. The trust placed in PVC welded wire mesh is evident through its widespread use in critical infrastructure and widespread endorsement by professionals in construction and civil engineering. This trust is built upon the repeated successful application in both standard conditions and challenging environments, consistently proving its credentials as a dependable material solution. Through continuous innovation, expertise, and quality assurance, PVC welded wire mesh emerges not just as a component of construction but as a pillar of modern infrastructure, blending tradition with technology to meet the demands of an evolving world.

Experience with PVC welded wire mesh speaks to its ease of installation, maintenance, and adaptability. Due to its lightweight nature, it simplifies the installation process, reducing manual labor and associated costs. Moreover, the low maintenance necessity born from its resilient coating means fewer resources are spent on upkeep, adding to its economic advantages. In environments prone to extreme weather conditions, PVC welded wire mesh has proven to maintain structural integrity better than galvanized steel wire alternatives. For contractors and builders prioritizing environmental sustainability, PVC welded wire mesh offers an eco-friendly option. The materials used in its production can be recycled, and the manufacturing process can be tailored to reduce environmental impact, addressing both industry and consumer demand for greener building solutions. The trust placed in PVC welded wire mesh is evident through its widespread use in critical infrastructure and widespread endorsement by professionals in construction and civil engineering. This trust is built upon the repeated successful application in both standard conditions and challenging environments, consistently proving its credentials as a dependable material solution. Through continuous innovation, expertise, and quality assurance, PVC welded wire mesh emerges not just as a component of construction but as a pillar of modern infrastructure, blending tradition with technology to meet the demands of an evolving world.

Next:

Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025