-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 19, 2024 16:20 Back to list

welded wire mesh panels manufacturer

The Importance of Welded Wire Mesh Panels A Comprehensive Overview

Welded wire mesh panels have become a staple in various industries for their strength, versatility, and cost-effectiveness. As a manufacturer in this domain, understanding the significance of these panels, their applications, and the production process is vital for both creators and users alike.

What are Welded Wire Mesh Panels?

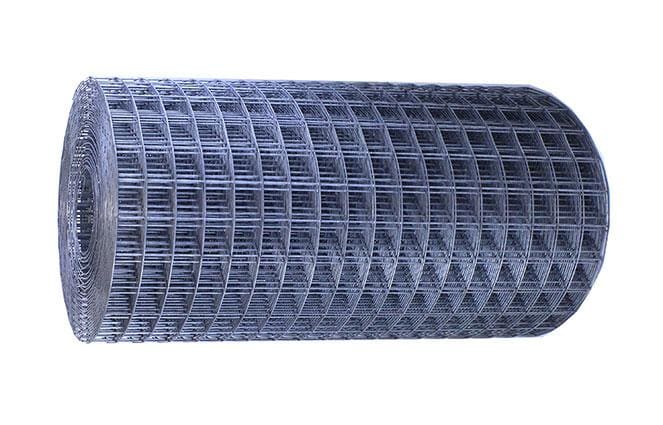

Welded wire mesh panels are made from steel wires that are welded together at their intersections, creating a grid-like structure. The manufacturing process typically involves high-quality steel wires that are arranged in a uniform pattern, often in rolls or flat panels. These panels come in various diameters, mesh sizes, and dimensions, making them suitable for a wide range of applications.

Benefits of Welded Wire Mesh Panels

1. Strength and Durability One of the primary advantages of welded wire mesh panels is their incredible strength. The welding process ensures that the wires are securely fastened at their intersections, providing a robust structure that can withstand heavy weights and resist deformation over time. This durability makes them ideal for use in construction, fencing, and other applications where strength is crucial.

2. Cost-Effectiveness Compared to other forms of reinforcement and fencing materials, welded wire mesh panels are often more affordable. This cost-effectiveness makes them a preferred choice for many projects, especially when large quantities are needed. Additionally, their long lifespan reduces the need for frequent replacements, leading to further savings over time.

3. Versatility The wide range of applications for welded wire mesh panels cannot be overstated. They are commonly used in construction for concrete reinforcement, as formwork, in the automotive industry for manufacturing parts, and for creating barriers and fencing in agricultural settings. This versatility makes them an essential product for manufacturers across various sectors.

4. Ease of Installation Welded wire mesh panels are generally easy to handle and install. They can be cut to size and shaped as needed, allowing for customization to meet specific project requirements. This ease of use reduces labor costs and ensures that projects can be completed more efficiently.

Applications of Welded Wire Mesh Panels

welded wire mesh panels manufacturer

1. Construction In the construction industry, welded wire mesh panels are used for reinforcing concrete in slabs, walls, and foundations. Their strength helps distribute loads evenly, preventing structural failures.

2. Fencing and Security Welded wire mesh panels are widely used for fencing in agricultural, industrial, and residential settings. Their robust construction provides security while allowing visibility and airflow.

3. Agriculture In the agricultural sector, these panels are utilized for everything from animal enclosures to plant supports. They provide an effective way to keep livestock secure while allowing for proper ventilation and light.

4. Industrial Applications In industrial settings, welded wire mesh panels serve various functions, including storage containment, machine guards, and more. Their adaptability makes them useful in numerous configurations.

Manufacturing Process

The production of welded wire mesh panels involves several steps. First, high-quality steel wires are drawn to the desired thickness. These wires are then arranged in a grid and welded together at controlled junction points using advanced welding techniques. The panels are often treated for corrosion resistance, ensuring longevity in various environmental conditions. Finally, quality control processes are implemented to inspect the panels for strength, integrity, and compliance with industry standards.

Choosing a Reliable Manufacturer

When selecting a manufacturer for welded wire mesh panels, it is crucial to consider their expertise and reputation in the industry. Look for manufacturers who employ high-quality materials, have a proven production process, and offer various customization options. Additionally, customer service and support should not be overlooked, as these factors can significantly impact your purchasing experience.

Conclusion

Welded wire mesh panels represent a significant innovation in manufacturing, providing unparalleled strength and versatility across multiple applications. Their cost-effectiveness, ease of installation, and durability make them a preferred choice for professionals in various industries. As manufacturers continue to innovate and improve production techniques, the demand for these panels is likely to remain strong, paving the way for new applications and advancements. Whether you’re in construction, agriculture, or any other field, investing in high-quality welded wire mesh panels is undoubtedly a step towards ensuring efficiency and reliability in your projects.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025