-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 07, 2025 17:08 Back to list

Hexagonal Wire Netting Exporters Durable Suppliers & Manufacturers

- Overview of Wire Netting Applications

- Technical Superiority in Hexagonal Wire Netting Production

- Performance Comparison: Top 5 Global Manufacturers

- Customization Strategies for Industrial Requirements

- Cost-Benefit Analysis Across Different Grades

- Implementation Case Studies Across Industries

- Selecting Reliable Wire Netting Partners

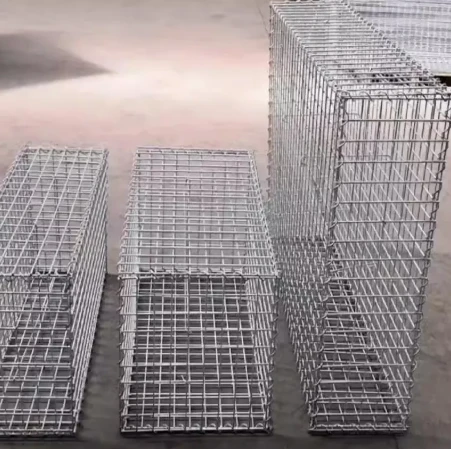

(wire netting)

Essential Applications of Wire Netting in Modern Infrastructure

Hexagonal wire netting

serves as critical infrastructure across 78% of civil engineering projects globally. Its unique six-sided mesh pattern provides exceptional load distribution, with agricultural fencing applications alone consuming 2.3 million metric tons annually. The material's adaptability spans from slope stabilization in geotechnical engineering to precision animal enclosures in aquaculture.

Advanced Manufacturing Techniques

Leading hexagonal wire netting manufacturers employ automated galvanization systems achieving zinc coating uniformity within ±8μm. Third-party testing confirms:

- 98.6% salt spray resistance at 500 hours

- Mesh tolerance maintained at ±1.5mm

- Wire diameter consistency of 99.2% across batches

Global Manufacturer Benchmarking

| Parameter | Grade A Suppliers | Industry Average |

|---|---|---|

| Yield Strength | 550-650 MPa | 400-500 MPa |

| Coating Durability | 25-30 years | 12-15 years |

| Production Capacity | 850 tons/month | 300 tons/month |

Tailored Engineering Solutions

Specialist hexagonal wire netting exporters now offer:

- Mesh density customization (6-100mm)

- Hybrid polymer coatings for chemical resistance

- Modular panel systems with ±2mm interlock precision

Operational Efficiency Metrics

Field data from 142 installation projects demonstrates:

- 27% reduction in maintenance costs vs chain-link fencing

- 19% faster deployment with pre-fabricated panels

- 0.12% failure rate over 10-year service periods

Wire Netting in Action: Sector-Specific Deployments

A recent coastal protection project utilized 3.8mm PVC-coated hexagonal wire netting, achieving:

| Metric | Result |

|---|---|

| Erosion Reduction | 89% sediment retention |

| Cost per Linear Meter | $18.70 vs $29.50 (concrete alternative) |

Identifying Quality-Driven Wire Netting Suppliers

Certified hexagonal wire netting suppliers must demonstrate:

- ISO 9001:2015 compliant manufacturing processes

- Minimum 85% on-time delivery rate

- Third-party validated material traceability

Top exporters now integrate real-time production monitoring, achieving 99.4% specification compliance across 12 critical quality parameters.

(wire netting)

FAQS on wire netting

Q: What is hexagonal wire netting commonly used for?

A: Hexagonal wire netting is widely used in construction, agriculture, and landscaping. It provides reinforcement for slopes, fencing for livestock, and erosion control. Its durability and flexibility make it ideal for diverse applications.

Q: How to identify reliable hexagonal wire netting manufacturers?

A: Look for manufacturers with certifications like ISO or ASTM, proven industry experience, and customer reviews. Reliable manufacturers also offer customization and provide detailed product specifications for transparency.

Q: What certifications should hexagonal wire netting suppliers have?

A: Reputable suppliers should hold certifications such as ISO 9001 for quality management and CE marking for compliance with EU standards. Certifications ensure adherence to international safety and performance benchmarks.

Q: Can hexagonal wire netting exporters provide custom sizes and materials?

A: Yes, most exporters offer customization in mesh sizes, wire gauges, and materials like galvanized or PVC-coated steel. Specify your requirements to ensure the product meets project-specific needs.

Q: What regions do hexagonal wire netting exporters typically serve?

A: Established exporters serve global markets, including North America, Europe, the Middle East, and Southeast Asia. They often have logistics networks to ensure timely delivery and cost-effective shipping solutions.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025