-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 09, 2025 12:35 Back to list

galvanized welded wire mesh

Wire mesh, an often-overlooked component, serves a critical role in various industries due to its versatility and strength. As a seasoned professional with years of experience in the field of wire products, I have seen the transformative impact of quality wire mesh solutions across numerous applications.

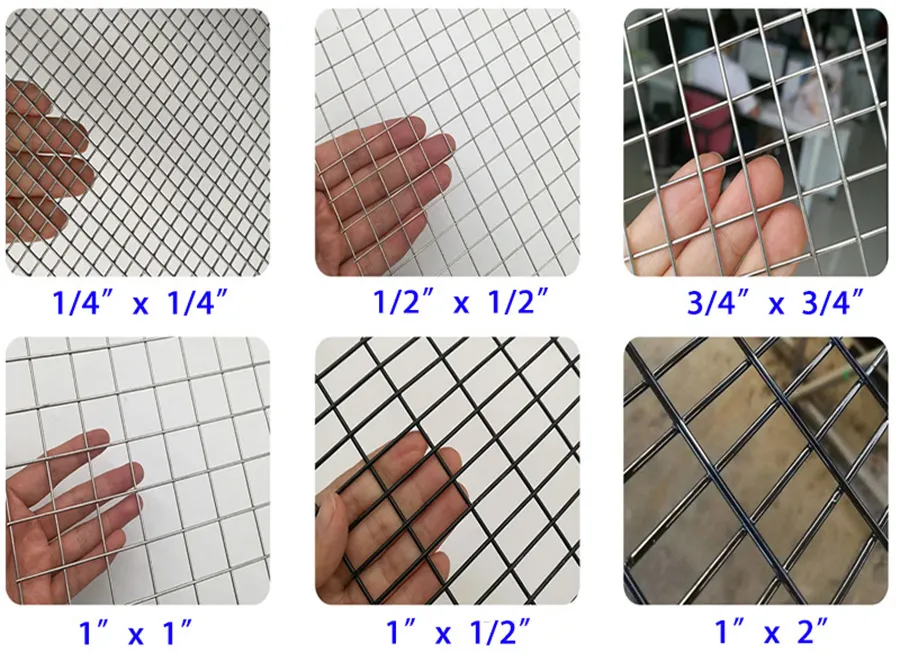

Professionally, I advocate for a detailed needs assessment before choosing wire mesh for any project. Understanding the precise requirements of the intended application—such as load stress, environmental conditions, and necessary lifespan—ensures optimal performance. Collaborating with suppliers who possess authoritative expertise and a track record of dependability can significantly enhance the product selection process. Trustworthiness in manufacturing practices is critical when considering wire mesh products. Reputable manufacturers adhere to stringent quality standards, ensuring that each batch of wire mesh is produced consistently to meet both safety and performance criteria. Products that carry certifications from established industry bodies provide an added assurance of quality and reliability. Moreover, the evolving technology in wire mesh production has paved the way for enhanced customization. Advanced techniques allow for precise control over mesh size, wire diameter, and pattern, enabling tailored solutions for complex projects. This level of customization underscores the importance of expertise and innovation in delivering high-performance wire mesh products. In conclusion, wire mesh is a foundational product across diverse sectors, offering unparalleled strength and versatility. Its value lies not only in its physical properties but also in the meticulous selection process and the authority of manufacturers. For those in pursuit of excellence, prioritizing professional guidance and quality assurance in wire mesh selection is essential for achieving superior outcomes.

Professionally, I advocate for a detailed needs assessment before choosing wire mesh for any project. Understanding the precise requirements of the intended application—such as load stress, environmental conditions, and necessary lifespan—ensures optimal performance. Collaborating with suppliers who possess authoritative expertise and a track record of dependability can significantly enhance the product selection process. Trustworthiness in manufacturing practices is critical when considering wire mesh products. Reputable manufacturers adhere to stringent quality standards, ensuring that each batch of wire mesh is produced consistently to meet both safety and performance criteria. Products that carry certifications from established industry bodies provide an added assurance of quality and reliability. Moreover, the evolving technology in wire mesh production has paved the way for enhanced customization. Advanced techniques allow for precise control over mesh size, wire diameter, and pattern, enabling tailored solutions for complex projects. This level of customization underscores the importance of expertise and innovation in delivering high-performance wire mesh products. In conclusion, wire mesh is a foundational product across diverse sectors, offering unparalleled strength and versatility. Its value lies not only in its physical properties but also in the meticulous selection process and the authority of manufacturers. For those in pursuit of excellence, prioritizing professional guidance and quality assurance in wire mesh selection is essential for achieving superior outcomes.

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025