-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 10, 2024 20:19 Back to list

Wire Mesh Fence Production Facilities and Their Key Features and Benefits

The Role of Wire Mesh in Fence Factories

Wire mesh has established itself as one of the most versatile materials used in the fabrication of fences. In the context of fence factories, wire mesh serves not only as a functional component but also as a cost-effective and aesthetically pleasing solution for various fencing needs. This article delves into the different types of wire mesh utilized in fence manufacturing, their applications, and the significant benefits they offer.

Understanding Wire Mesh

At its core, wire mesh consists of a network of intersecting wires that are either woven or welded together. The resulting product is available in numerous gauges and materials, offering a range of options for strength and flexibility. Common materials used include stainless steel, galvanized steel, vinyl-coated wire, and even aluminum. Each type possesses unique properties that make it suitable for different fencing applications.

Types of Wire Mesh Used in Fence Factories

1. Welded Wire Mesh This type of wire mesh is created by welding the wires at their intersections to create a robust, grid-like structure. Its high strength makes it ideal for residential, commercial, and industrial fencing. Welded wire fences are often employed in agricultural settings to contain livestock, while also providing protection against intruders.

2. Woven Wire Mesh Unlike welded wire mesh, woven wire mesh is made by weaving the wires together. This results in a more flexible product that can easily conform to varying terrains. It is typically used for ranch and farm fencing purposes, where it effectively contains animals and enhances security without obstructing visibility.

3. Chain Link Fencing Though technically a form of wire mesh, chain link fencing is worth mentioning due to its widespread use. It offers a durable and cost-effective fencing solution suitable for residential properties, playgrounds, and commercial spaces. Often coated with a protective layer of vinyl or galvanized material, chain link fences resist rust and weather conditions, making them a long-lasting choice.

4. Vinyl Coated Wire Mesh For those seeking a decorative touch in addition to security, vinyl-coated wire mesh offers an appealing alternative. Available in various colors, this type of mesh not only enhances visual appeal but also contributes to durability by providing additional protection against corrosion.

Applications of Wire Mesh Fencing

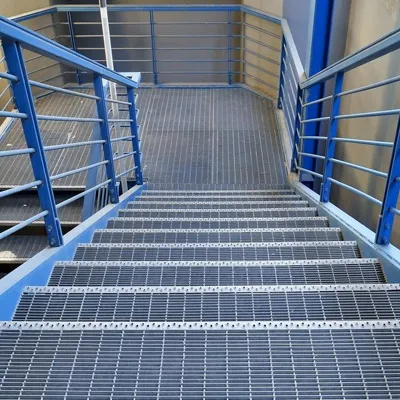

wire mesh for fence factories

Wire mesh fencing is exceptionally diverse, making it appropriate for a vast array of applications. In addition to the aforementioned residential and agricultural uses, wire mesh can also be found in industrial settings where it secures perimeters and protects valuable assets. Sports facilities often utilize this type of fencing for security and crowd control, while schools benefit from its ability to create safe play areas without hindering visibility.

Wire mesh fencing is also frequently employed in correctional facilities. The strength and durability of welded wire mesh make it an ideal choice for maintaining security in these environments, deterring escape attempts effectively.

Benefits of Wire Mesh Fencing

1. Cost-Effective One of the primary advantages of using wire mesh in fencing is its affordability. Wire mesh fences offer a low initial investment while requiring minimal maintenance over time.

2. Durability Wire mesh is designed to withstand various environmental conditions. Whether it’s rain, snow, or extreme heat, it maintains its structural integrity, leading to a long lifespan.

3. Visibility Unlike solid barriers, wire mesh fences maintain visibility, allowing for unobstructed sightlines. This feature can be particularly important in residential neighborhoods and monitored areas.

4. Versatility Wire mesh can be customized to meet various specifications regarding height, gauge, and coating options, making it suitable for virtually any application, from safety to aesthetic purposes.

Conclusion

Wire mesh fencing represents a crucial element in the manufacturing processes of fence factories. With a wide variety of types and applications, it offers a blend of strength, durability, and cost-effectiveness. As demand for secure yet visually appealing fencing solutions continues to grow, wire mesh will undoubtedly remain a popular choice among consumers and manufacturers alike. Whether for residential, commercial, or industrial use, wire mesh has proven to be an invaluable material in the fencing industry.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025