-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 14, 2024 09:55 Back to list

wire mesh panel manufacturers

Wire Mesh Panel Manufacturers An Overview

Wire mesh panels have become an essential component across various industries, serving a multitude of applications from construction to agriculture. With their versatility, strength, and cost-effectiveness, it's no wonder that the demand for wire mesh panels has grown dramatically. This article delves into the attributes of wire mesh panels and the role of manufacturers in producing these indispensable products.

What Are Wire Mesh Panels?

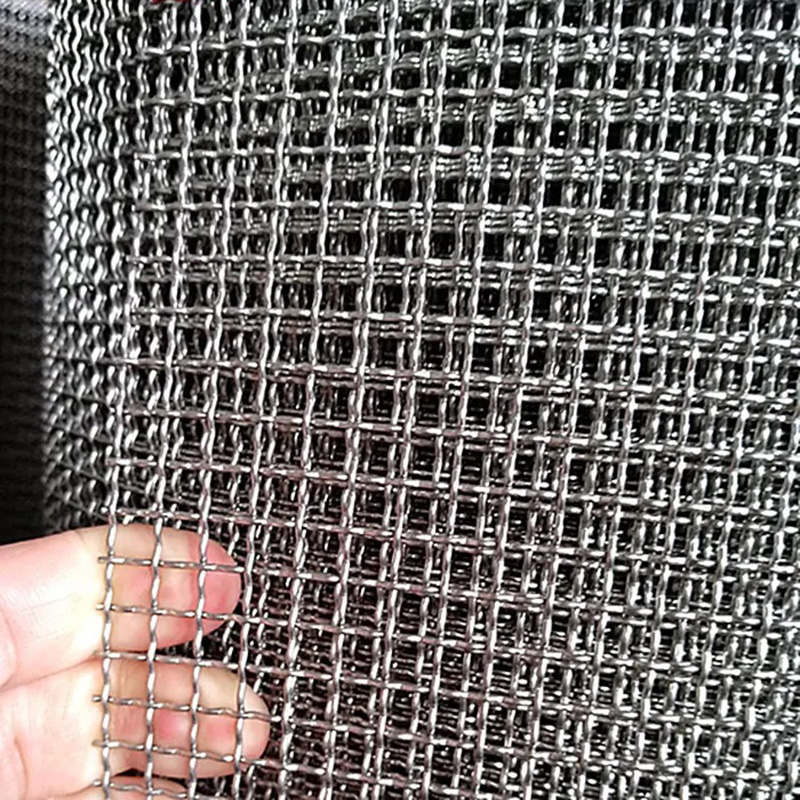

Wire mesh panels are made from interwoven or welded wires that create a grid-like structure. They can be manufactured in various gauges and materials, typically steel, stainless steel, or aluminum, depending on the intended use. These panels come in different sizes, shapes, and configurations, allowing for customized solutions to meet specific requirements.

The uses of wire mesh panels are extensive. In construction, they serve as reinforcement for concrete, providing added strength to structures. In agriculture, they are commonly used for fencing, creating enclosures for livestock, or as trellising for climbing plants. Additionally, these panels are used in security applications, filtration systems, and transportation, among many others.

The Role of Manufacturers

The manufacturing process of wire mesh panels is crucial in determining their quality and performance. Reputable wire mesh panel manufacturers adhere to rigorous standards to ensure their products meet industry specifications. This includes selecting high-quality raw materials, implementing state-of-the-art technology, and employing skilled labor.

Material Specifications

wire mesh panel manufacturers

Manufacturers often offer a variety of materials to cater to diverse needs. For instance, galvanized steel is frequently used for outdoor applications due to its corrosion resistance, while stainless steel is favored for its durability and aesthetic appeal. Aluminum, being lightweight yet strong, is an excellent choice for portable fencing solutions.

Production Techniques

Wire mesh panels can be produced using different techniques, primarily welding and weaving. The welding process involves fusing the wires at intersections to create a strong bond, resulting in a rigid structure. In contrast, weaving involves interlacing the wires, which may provide a more flexible mesh suitable for specific applications. Each technique has its advantages, and manufacturers often choose based on the intended use of the product.

Quality Assurance

Quality assurance is a vital aspect of wire mesh panel manufacturing. Leading manufacturers implement strict quality control measures throughout the production process, from raw material inspection to final product testing. This diligence ensures that the panels produced are not only safe for use but also meet the performance expectations of their customers.

Conclusion

In summary, wire mesh panels serve a wide array of functions, and their importance across various industries cannot be overstated. Manufacturers play a pivotal role in ensuring these products are crafted to the highest standards, using quality materials and advanced production techniques. As industries continue to evolve, the demand for reliable and innovative wire mesh panel solutions will only increase. Companies seeking to utilize wire mesh panels for their specific applications should partner with experienced manufacturers who can deliver quality products tailored to their needs. This collaboration is vital for ensuring safety, durability, and efficiency in any project where wire mesh panels are employed.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025