-

+86 15030157877

-

sales@galvanizedmetalmesh.com

feb . 12, 2025 03:09 Back to list

custom hexagonal wire mesh

When it comes to reinforcing concrete structures, customized welded mesh has proven to be a game-changer in the construction industry. Combining precision engineering with tailor-made designs, custom welded mesh provides an unparalleled level of support and stability to concrete projects, ultimately enhancing durability and safety. This article explores the profound impact of custom welded mesh and why it has become essential for modern construction.

Trustworthiness of custom welded mesh manufacturers is further established through transparent business practices and a commitment to sustainable production methods. By prioritizing eco-friendly manufacturing processes and sourcing recycled materials, these firms not only reduce their carbon footprint but also appeal to environmentally conscious clients. Additionally, reputable manufacturers offer comprehensive warranties and post-sales support, ensuring that any issues are promptly addressed and resolved to maintain customer confidence and satisfaction. The shift towards custom welded mesh for concrete projects has also been influenced by its long-term economic and environmental benefits. By designing reinforcement that precisely fits structural requirements, there is a reduction in raw material usage, contributing to lowered project costs. Longevity is another economic advantage, as the durability of welded mesh mitigates the need for frequent repairs or replacements, thereby conserving resources over the lifecycle of a structure. For construction companies aiming to remain competitive, adopting custom welded mesh represents a forward-thinking approach that aligns with modern engineering practices. It embodies the principles of efficiency, quality, and sustainability—values that are becoming increasingly important in today’s architectural landscape. Custom welded mesh stands out as not merely a product but a strategic asset that adds significant value to construction projects. In essence, custom welded mesh has become synonymous with innovation in concrete reinforcement. By leveraging precise manufacturing, expert engineering, and sustainable practices, it meets the ever-evolving demands of the construction industry, ensuring projects are not only executed successfully but also exceed expectations in safety and performance.

Trustworthiness of custom welded mesh manufacturers is further established through transparent business practices and a commitment to sustainable production methods. By prioritizing eco-friendly manufacturing processes and sourcing recycled materials, these firms not only reduce their carbon footprint but also appeal to environmentally conscious clients. Additionally, reputable manufacturers offer comprehensive warranties and post-sales support, ensuring that any issues are promptly addressed and resolved to maintain customer confidence and satisfaction. The shift towards custom welded mesh for concrete projects has also been influenced by its long-term economic and environmental benefits. By designing reinforcement that precisely fits structural requirements, there is a reduction in raw material usage, contributing to lowered project costs. Longevity is another economic advantage, as the durability of welded mesh mitigates the need for frequent repairs or replacements, thereby conserving resources over the lifecycle of a structure. For construction companies aiming to remain competitive, adopting custom welded mesh represents a forward-thinking approach that aligns with modern engineering practices. It embodies the principles of efficiency, quality, and sustainability—values that are becoming increasingly important in today’s architectural landscape. Custom welded mesh stands out as not merely a product but a strategic asset that adds significant value to construction projects. In essence, custom welded mesh has become synonymous with innovation in concrete reinforcement. By leveraging precise manufacturing, expert engineering, and sustainable practices, it meets the ever-evolving demands of the construction industry, ensuring projects are not only executed successfully but also exceed expectations in safety and performance.

Next:

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

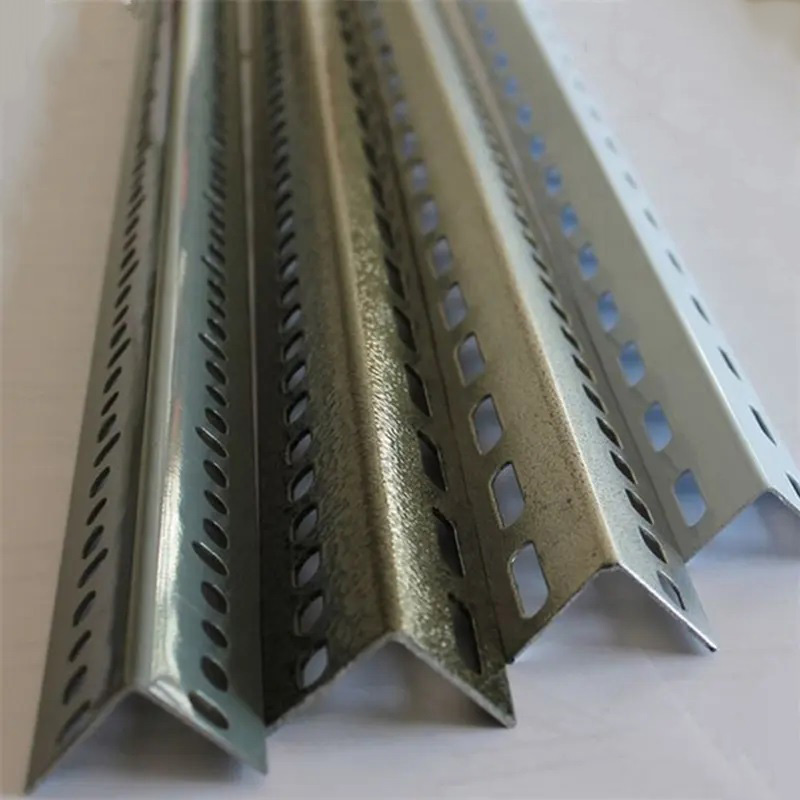

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025