-

+86 15030157877

-

sales@galvanizedmetalmesh.com

jan . 25, 2025 21:11 Back to list

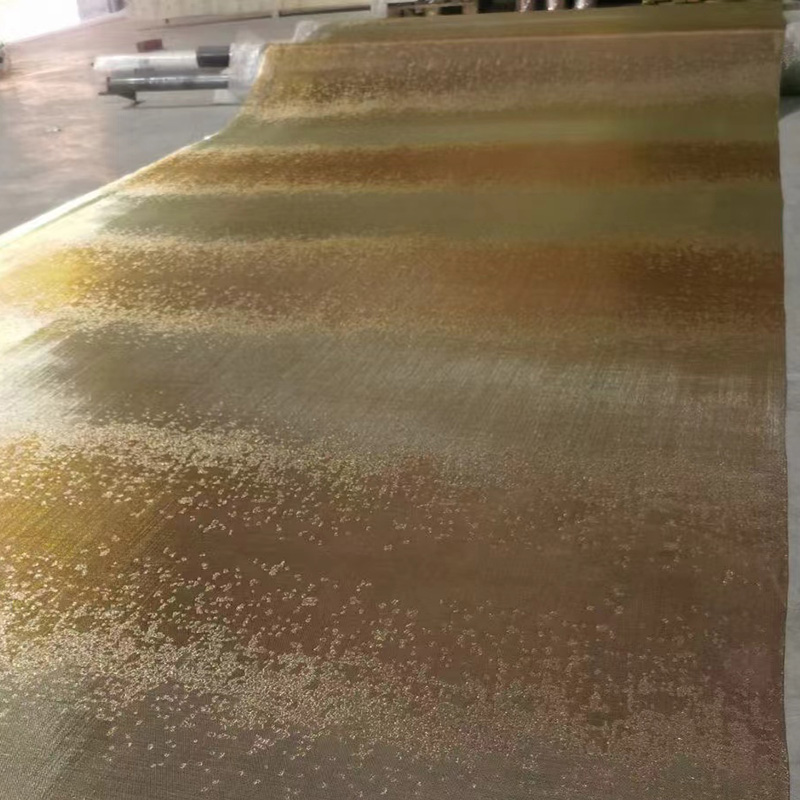

galvanized hexagonal wire mesh

Galvanized hexagonal wire mesh has become a cornerstone in various industries, offering exceptional benefits and versatility that cater to a diverse range of applications. With its unique design and robust nature, this wire mesh stands out as a product that intertwines practicality and reliability, making it a go-to choice for both commercial and industrial purposes.

Trustworthiness in product selection and deployment cannot be overstated, and galvanized hexagonal wire mesh boasts a storied history of reliability. Consumers and professionals alike have consistently documented its robust performance. Testimonials often point towards minimal maintenance needs after installation, which not only reduces costs but also assures users of consistent results. Additionally, suppliers typically adhere to stringent quality control processes, ensuring that each batch of wire mesh meets the rigorous standards expected by end-users. This consistency boosts consumer confidence and invariably establishes the product as a trustworthy material choice for any project. The practical advantages of galvanized hexagonal wire mesh extend beyond durability and versatility. The product is inherently eco-friendly. The mesh can be fully recycled, and the energy-efficient galvanization process reduces overall environmental impact, aligning with the increasing global emphasis on sustainable development. For environmentally-conscious projects, this facet of the wire mesh provides an attractive proposition, marrying utility with ecological responsibility. In conclusion, galvanized hexagonal wire mesh remains a superior material from every angle. Whether through the lens of experience, showcasing years of unyielding resilience, or expertise that highlights engineering marvels in its design, the wire mesh emerges as a vital component across multiple sectors. Its authoritative position in the market, underscored by proven versatility and dependability, speaks volumes about its efficacy in demanding applications. Above all, its trustworthiness and minimal ecological impact provide added assurance to users, making it not only a barrier or support structure but a testament to the fusion of innovation and sustainability.

Trustworthiness in product selection and deployment cannot be overstated, and galvanized hexagonal wire mesh boasts a storied history of reliability. Consumers and professionals alike have consistently documented its robust performance. Testimonials often point towards minimal maintenance needs after installation, which not only reduces costs but also assures users of consistent results. Additionally, suppliers typically adhere to stringent quality control processes, ensuring that each batch of wire mesh meets the rigorous standards expected by end-users. This consistency boosts consumer confidence and invariably establishes the product as a trustworthy material choice for any project. The practical advantages of galvanized hexagonal wire mesh extend beyond durability and versatility. The product is inherently eco-friendly. The mesh can be fully recycled, and the energy-efficient galvanization process reduces overall environmental impact, aligning with the increasing global emphasis on sustainable development. For environmentally-conscious projects, this facet of the wire mesh provides an attractive proposition, marrying utility with ecological responsibility. In conclusion, galvanized hexagonal wire mesh remains a superior material from every angle. Whether through the lens of experience, showcasing years of unyielding resilience, or expertise that highlights engineering marvels in its design, the wire mesh emerges as a vital component across multiple sectors. Its authoritative position in the market, underscored by proven versatility and dependability, speaks volumes about its efficacy in demanding applications. Above all, its trustworthiness and minimal ecological impact provide added assurance to users, making it not only a barrier or support structure but a testament to the fusion of innovation and sustainability.

Next:

Latest news

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025