-

+86 15030157877

-

sales@galvanizedmetalmesh.com

jan . 06, 2025 19:02 Back to list

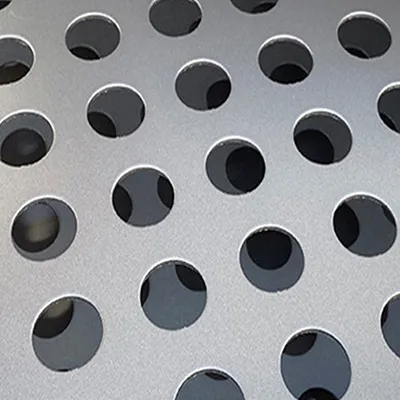

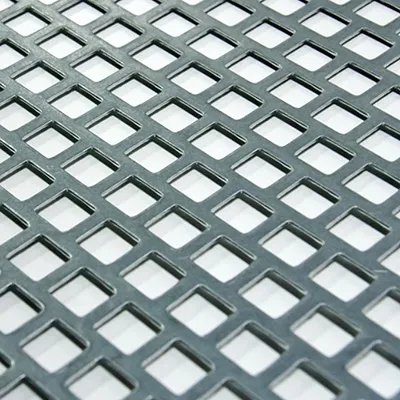

metal stainless steel perforated metal mesh

Metal mesh is a remarkable product that combines strength, flexibility, and a wide array of applications, making it a standout choice in numerous industries. With decades of experience in engineering and material sciences, the use of metal mesh has evolved, transforming industries from construction to electronics. A deep dive into its applications and benefits reveals why it is a preferred choice for so many professionals globally.

Metal mesh is primarily constructed from materials such as stainless steel, aluminum, and copper, each selected for their unique properties. The choice of metal is critical, as it dictates the mesh’s performance attributes, such as corrosion resistance, weight, and conductivity. Stainless steel is renowned for its durability and resistance to corrosive environments, making it suitable for outdoor and marine applications. Aluminum, being lightweight yet strong, is often used in automotive and aerospace sectors, whereas copper's excellent electrical conductivity makes it desirable for electronic and telecommunication uses.

In the construction industry, metal mesh is often used for reinforcement, offering enhanced tensile strength and stability to concrete structures. This application has revolutionized the way architects and engineers design buildings, allowing for more innovative and sustainable structures. Beyond reinforcement, metal mesh serves as an aesthetic element, offering both functionality and beauty with a variety of patterns and finishes. It is used for cladding, fencing, and even artistic installations, contributing to modern architecture's sleek and industrial aesthetic.

The environmental benefits of metal mesh should not be overlooked. In an era where sustainability is of paramount importance, metal mesh offers a recyclable solution. Many metal meshes are made from recycled materials and can be recycled at the end of their life cycle, thus promoting a circular economy. This aspect alone enhances its appeal to environmentally conscious projects seeking LEED certification or other sustainable building standards.

In the realm of electronics, metal mesh serves as an essential component for shielding. Electromagnetic interference (EMI) shielding is crucial in protecting sensitive electronic devices from disruptive electromagnetic fields. Metal mesh is also pivotal in the development of touch screen technology, providing the conductive surface necessary for capacitive touch sensors found in smartphones, tablets, and interactive kiosks.

metal mesh

The versatility of metal mesh doesn't end here. In the realm of filtration, metal mesh is celebrated for its precision and durability. Whether filtering air, liquids, or gases, metal mesh outperforms traditional materials due to its ability to withstand high pressures and temperatures. This makes it invaluable in industries such as petroleum, pharmaceuticals, and food processing, where stringent standards are non-negotiable.

With an extensive range of mesh openings and a variety of weaves, the customization potential is enormous, catering to precise specifications for specialized industrial needs. This adaptability is complemented by advancements in manufacturing technology, allowing for more complex designs and higher quality products at reduced costs.

Professionals who seek to utilize metal mesh in their projects can rely on its proven track record of reliability and performance, underscored by rigorous testing and adherence to international standards. As a trusted solution in challenging environments, its authority comes not just from its physical properties but also from the extensive research and development that support it.

For those seeking an innovative and trusted solution that stands the test of time, metal mesh proves to be a formidable contender. Its applications are ever-expanding, driven by technological advancements and the persistent demand for durable, efficient, and versatile materials. Whether for safeguarding electronics, reinforcing structures, or providing intricate architectural details, metal mesh remains an indispensable resource in the modern world.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025