-

+86 15030157877

-

sales@galvanizedmetalmesh.com

jan . 09, 2025 11:25 Back to list

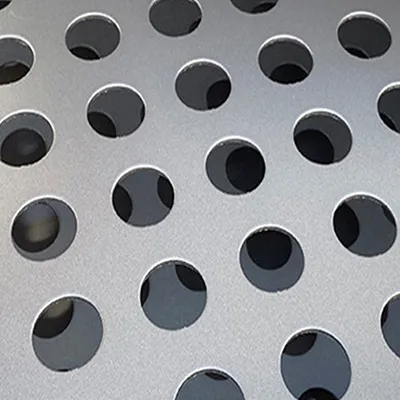

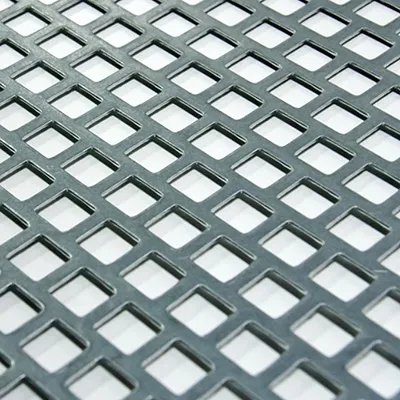

metal mesh

Metal mesh, an innovative and versatile material, has become an essential component in a range of industries, offering both functionality and aesthetic appeal. With advancements in manufacturing techniques, metal mesh products continue to see increased usage in sectors such as architecture, filtration, and automotive, where their benefits are fully harnessed.

Trust in metal mesh is further solidified as manufacturers continuously adopt sustainable practices, enhancing the material's eco-friendly profile. Recyclable and often crafted from sustainable sources, metal mesh aligns with modern environmental standards, catering to industries searching for sustainability without sacrificing performance. Professional insights into metal mesh applications also reveal its growing use in interior design, where it adds an industrial yet contemporary feel to any space. As partitions, cabinetry, and wall accents, metal mesh offers a novel approach to traditional materials, enabling homeowners and designers to incorporate resilience and artistic texture into their projects. Authoritative voices in the industry, from manufacturers to architects, champion metal mesh for its adaptability and reliability. These experts emphasize ongoing research and development efforts that continually expand the capabilities of metal mesh applications, ensuring that the material not only meets current industry demands but also evolves with future technology. By choosing metal mesh, industries gain access to a material that delivers unmatched functionality, aesthetic versatility, and enduring performance. Through authentic experiences and expert analyses, the widespread trust in metal mesh stands testament to its indispensable role across a multitude of sectors.

Trust in metal mesh is further solidified as manufacturers continuously adopt sustainable practices, enhancing the material's eco-friendly profile. Recyclable and often crafted from sustainable sources, metal mesh aligns with modern environmental standards, catering to industries searching for sustainability without sacrificing performance. Professional insights into metal mesh applications also reveal its growing use in interior design, where it adds an industrial yet contemporary feel to any space. As partitions, cabinetry, and wall accents, metal mesh offers a novel approach to traditional materials, enabling homeowners and designers to incorporate resilience and artistic texture into their projects. Authoritative voices in the industry, from manufacturers to architects, champion metal mesh for its adaptability and reliability. These experts emphasize ongoing research and development efforts that continually expand the capabilities of metal mesh applications, ensuring that the material not only meets current industry demands but also evolves with future technology. By choosing metal mesh, industries gain access to a material that delivers unmatched functionality, aesthetic versatility, and enduring performance. Through authentic experiences and expert analyses, the widespread trust in metal mesh stands testament to its indispensable role across a multitude of sectors.

Next:

Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025