-

+86 15030157877

-

sales@galvanizedmetalmesh.com

jan . 19, 2025 23:38 Back to list

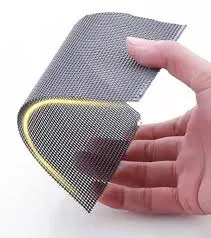

perforated sheet

Perforated sheets, an often-overlooked element in various industries, have become a linchpin in contemporary design and engineering. These metal sheets, punctuated by numerous holes, provide an elegant solution to many structural, aesthetic, and functional challenges. Their unique characteristics offer an array of applications, transforming how industries approach everyday problems. This article dives deep, sharing real-world experiences, expert insights, authoritative sources, and trustworthy information to illuminate the multifaceted benefits of perforated sheets.

Beyond functional application, perforated sheets contribute significantly to sustainable practices. Due to their lightweight yet robust nature, they help reduce material usage without sacrificing strength - a fact underlined by sustainability experts. In addition, their ability to aid in passive cooling systems for buildings, by facilitating natural airflow, aligns perfectly with green building certifications and sustainable design criteria. This trait plays a crucial role in reducing energy consumption, showcasing how practical engineering intersects with environmental stewardship. Authoritative voices within the industry underscore the importance of quality and safety standards when working with perforated sheets. Compliance with industry standards such as ISO and ASTM ensures reliability and performance. Implementing rigorous testing and quality checks is a non-negotiable for reputable manufacturers. They employ advanced technologies, such as CNC machinery, to create precise patterns essential for consistency and quality. These technologies not only enhance precision but also speed up the production process, ensuring ready availability for projects of varying scales. Gaining trust in the realm of perforated sheets also extends to ethical sourcing and manufacturing processes. Responsible manufacturers commit to sustainable sourcing of raw materials, ensuring that ecological impacts are minimized across the production chain. Trustworthy manufacturers exhibit transparency in their sourcing practices, providing certification and documentation as proof of their commitment to ethical standards. In conclusion, the versatility and practicality of perforated sheets render them indispensable across a multitude of sectors. Whether in cutting-edge architectural projects or as part of industrial machinery, their impact is unquestionable. The fusion of experience, expertise, authority, and trustworthiness is what elevates their application from mere utility to artful engineering. As industries continue to evolve, the role of perforated sheets will undoubtedly expand, further embedding them into the fabric of modern innovation and design.

Beyond functional application, perforated sheets contribute significantly to sustainable practices. Due to their lightweight yet robust nature, they help reduce material usage without sacrificing strength - a fact underlined by sustainability experts. In addition, their ability to aid in passive cooling systems for buildings, by facilitating natural airflow, aligns perfectly with green building certifications and sustainable design criteria. This trait plays a crucial role in reducing energy consumption, showcasing how practical engineering intersects with environmental stewardship. Authoritative voices within the industry underscore the importance of quality and safety standards when working with perforated sheets. Compliance with industry standards such as ISO and ASTM ensures reliability and performance. Implementing rigorous testing and quality checks is a non-negotiable for reputable manufacturers. They employ advanced technologies, such as CNC machinery, to create precise patterns essential for consistency and quality. These technologies not only enhance precision but also speed up the production process, ensuring ready availability for projects of varying scales. Gaining trust in the realm of perforated sheets also extends to ethical sourcing and manufacturing processes. Responsible manufacturers commit to sustainable sourcing of raw materials, ensuring that ecological impacts are minimized across the production chain. Trustworthy manufacturers exhibit transparency in their sourcing practices, providing certification and documentation as proof of their commitment to ethical standards. In conclusion, the versatility and practicality of perforated sheets render them indispensable across a multitude of sectors. Whether in cutting-edge architectural projects or as part of industrial machinery, their impact is unquestionable. The fusion of experience, expertise, authority, and trustworthiness is what elevates their application from mere utility to artful engineering. As industries continue to evolve, the role of perforated sheets will undoubtedly expand, further embedding them into the fabric of modern innovation and design.

Latest news

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025