-

+86 15030157877

-

sales@galvanizedmetalmesh.com

lut . 15, 2025 07:52 Back to list

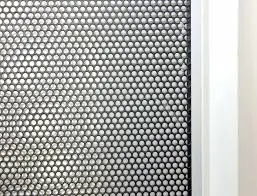

Galvanized/PVC Coated Hexagonal Wire Mesh

Custom electro galvanized wire, a powerhouse in the industrial and construction sectors, has been gaining traction due to its exceptional properties and versatile applications. This wire is crafted through an electroplating process that applies a thin layer of zinc to the steel wire, creating a protective barrier against corrosion and enhancing its longevity. This innovation is not just a testament to advanced metallurgical expertise but also a reflection of reliability in environments that demand durability.

In terms of authoritativeness, the utilization of electro galvanized wire is backed by rigorous industry standards and certifications. These standards guarantee that the wire meets stringent quality and safety benchmarks, providing an added layer of assurance to contractors and end-users. Moreover, the extensive research and development invested in enhancing galvanization techniques underscore the authority of this material in global supply chains. Trustworthiness is a cornerstone of using custom electro galvanized wire, particularly when sourced from reputable suppliers. These suppliers provide transparency in their manufacturing processes, offer comprehensive warranties, and uphold ethical production practices. They also provide detailed documentation and testing reports, allowing customers to make informed decisions based on factual data and performance metrics. This transparency not only strengthens consumer trust but also solidifies the wire’s position as a dependable component in critical infrastructure projects. In conclusion, custom electro galvanized wire embodies a synthesis of cutting-edge technology, material science, and environmental mindfulness. Its adaptability, coupled with demonstrated expertise and industry support, makes it an indispensable asset across various applications. Whether you are an engineer designing complex structures or a contractor seeking reliable materials, the advantages of electro galvanized wire provide peace of mind, ensuring your projects stand the test of time. Embrace the strength and versatility of custom electro galvanized wire and elevate the quality and durability of your next project.

In terms of authoritativeness, the utilization of electro galvanized wire is backed by rigorous industry standards and certifications. These standards guarantee that the wire meets stringent quality and safety benchmarks, providing an added layer of assurance to contractors and end-users. Moreover, the extensive research and development invested in enhancing galvanization techniques underscore the authority of this material in global supply chains. Trustworthiness is a cornerstone of using custom electro galvanized wire, particularly when sourced from reputable suppliers. These suppliers provide transparency in their manufacturing processes, offer comprehensive warranties, and uphold ethical production practices. They also provide detailed documentation and testing reports, allowing customers to make informed decisions based on factual data and performance metrics. This transparency not only strengthens consumer trust but also solidifies the wire’s position as a dependable component in critical infrastructure projects. In conclusion, custom electro galvanized wire embodies a synthesis of cutting-edge technology, material science, and environmental mindfulness. Its adaptability, coupled with demonstrated expertise and industry support, makes it an indispensable asset across various applications. Whether you are an engineer designing complex structures or a contractor seeking reliable materials, the advantages of electro galvanized wire provide peace of mind, ensuring your projects stand the test of time. Embrace the strength and versatility of custom electro galvanized wire and elevate the quality and durability of your next project.

Latest news

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025