-

+86 15030157877

-

sales@galvanizedmetalmesh.com

lut . 12, 2025 22:20 Back to list

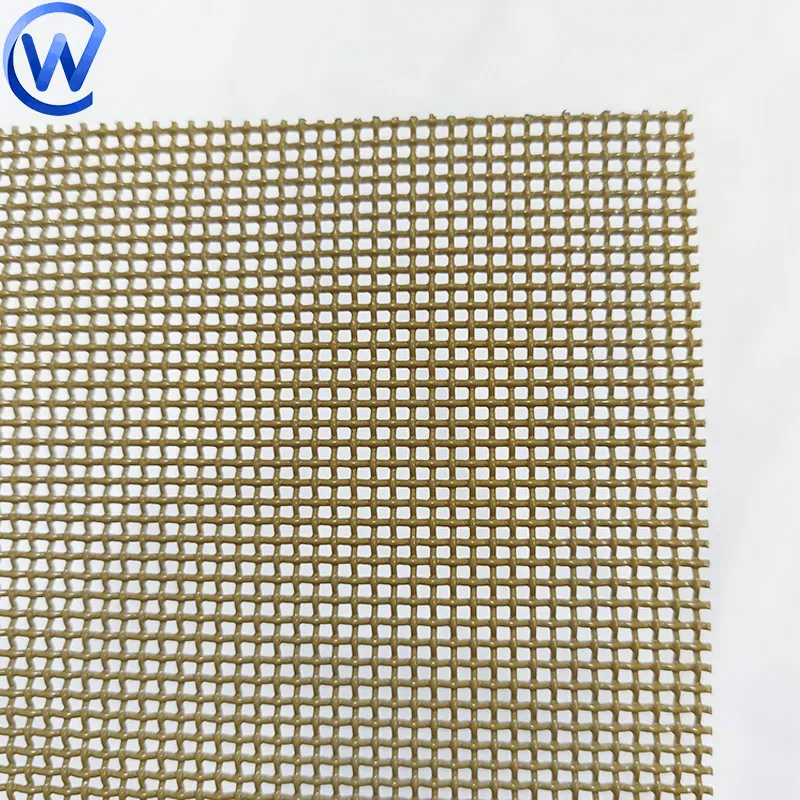

welded wire mesh roll

Custom mesh wire rolls have revolutionized various industries by offering tailored solutions that meet specific requirements and applications. In a world that demands customized solutions, these mesh wires stand out due to their versatility and adaptability, serving a vast array of sectors, from construction to aerospace. The journey to understand the impact and utility of custom mesh wire rolls begins with exploring their core advantages and applications.

For those invested in filtration solutions, custom mesh wire rolls offer unparalleled precision. In industries like pharmaceuticals and chemicals, where exacting standards are paramount, these mesh wires can be fabricated to provide precise filtration capabilities. This ensures product purity and quality, aligning with stringent industry regulations and standards. From a technical perspective, the expertise involved in crafting custom mesh wire rolls advocates for an authoritative knowledge base that guides decision-makers. Manufacturers equipped with state-of-the-art technology and experienced staff can provide insightful recommendations, ensuring that the product delivered is not only fit-for-purpose but also optimized for performance. Trustworthiness in this context is reflected by rigorous testing and quality assurance processes that underscore the reliability of custom mesh wire rolls. Accredited labs and inspection routines validate the consistency and performance of these mesh wires, aligning them with both national and international standards. For clients, this serves as an assurance of quality and safety, fostering confidence in their long-term use. The landscape of custom mesh wire rolls is continually shaped by scientific advancements and innovative manufacturing techniques. New fabrication methods such as laser cutting and computer numerical control (CNC) machining enhance precision and efficiency. These advancements reduces waste and lead time, offering clients superior products with improved turnaround times. In conclusion, custom mesh wire rolls epitomize the intersection of experience, expertise, authoritativeness, and trustworthiness. Their compelling value proposition lies in their versatility across multiple sectors, driven by customization to meet specific needs. For any industry professional or company seeking reliable, high-performance solutions, investing in custom mesh wire rolls promises not only innovation but also a sustainable partnership with quality and reliability at its core.

For those invested in filtration solutions, custom mesh wire rolls offer unparalleled precision. In industries like pharmaceuticals and chemicals, where exacting standards are paramount, these mesh wires can be fabricated to provide precise filtration capabilities. This ensures product purity and quality, aligning with stringent industry regulations and standards. From a technical perspective, the expertise involved in crafting custom mesh wire rolls advocates for an authoritative knowledge base that guides decision-makers. Manufacturers equipped with state-of-the-art technology and experienced staff can provide insightful recommendations, ensuring that the product delivered is not only fit-for-purpose but also optimized for performance. Trustworthiness in this context is reflected by rigorous testing and quality assurance processes that underscore the reliability of custom mesh wire rolls. Accredited labs and inspection routines validate the consistency and performance of these mesh wires, aligning them with both national and international standards. For clients, this serves as an assurance of quality and safety, fostering confidence in their long-term use. The landscape of custom mesh wire rolls is continually shaped by scientific advancements and innovative manufacturing techniques. New fabrication methods such as laser cutting and computer numerical control (CNC) machining enhance precision and efficiency. These advancements reduces waste and lead time, offering clients superior products with improved turnaround times. In conclusion, custom mesh wire rolls epitomize the intersection of experience, expertise, authoritativeness, and trustworthiness. Their compelling value proposition lies in their versatility across multiple sectors, driven by customization to meet specific needs. For any industry professional or company seeking reliable, high-performance solutions, investing in custom mesh wire rolls promises not only innovation but also a sustainable partnership with quality and reliability at its core.

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025