-

+86 15030157877

-

sales@galvanizedmetalmesh.com

lut . 15, 2025 06:33 Back to list

Galvanized/PVC Coated Hexagonal Wire Mesh

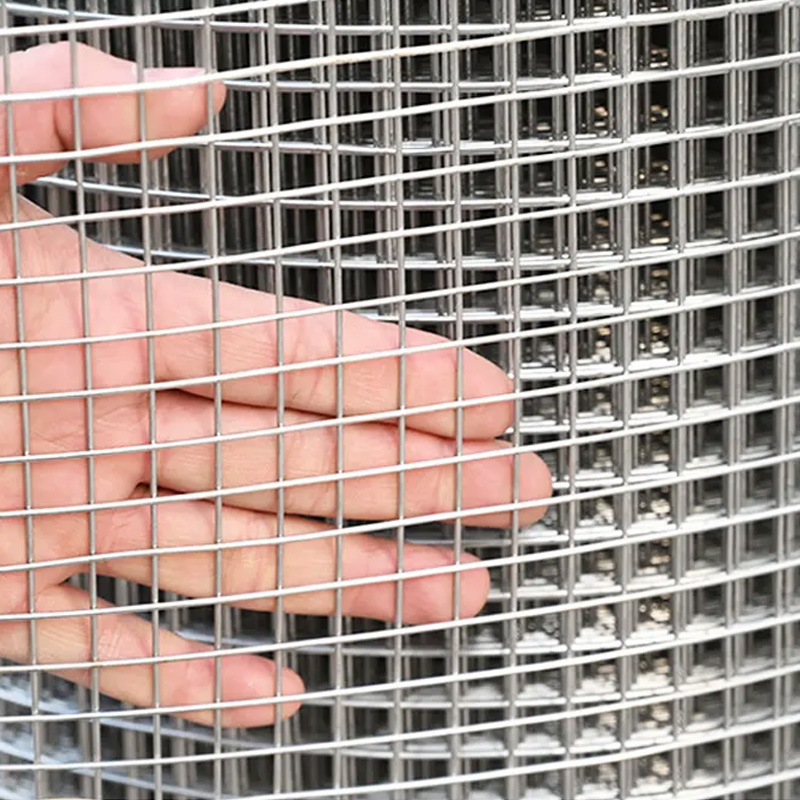

Custom welded wire mesh is an indispensable component in many construction and industrial projects, offering both versatility and durability. When crafted to precision, this mesh not only meets the specific needs of various applications but also bolsters the strength and longevity of the structures it supports.

The precision involved in crafting custom welded wire mesh cannot be overstated. Advanced welding techniques, such as automated welding processes, enhance the accuracy and consistency of the mesh. This results in uniform cross-sectional strength, which is critical for applications where even distribution of load is necessary. Whether the mesh is used in creating concrete slabs, fencing, or animal enclosures, the precision of the welds ensures maximum safety and efficacy. Case studies across various industries underscore the importance of using high-quality custom welded wire mesh. In the agricultural sector, for example, custom mesh has been utilized to create enclosures that protect livestock while providing ventilation and visibility. This not only safeguards the animals but also simplifies farm management practices. Construction projects often demand custom welded wire mesh for reinforcement purposes. One notable example is its use in road construction, where the mesh helps distribute stress and prevent cracking. The use of customized solutions allows engineers to address specific challenges unique to each project site, enhancing the lifespan and safety of infrastructure. In the automotive industry, custom welded wire mesh finds applications in vehicle manufacturing, particularly in creating sturdy, lightweight components that contribute to fuel efficiency. The customization ensures that each mesh component fits perfectly and performs under demanding conditions. In conclusion, custom welded wire mesh remains a cornerstone in various fields due to its adaptability, precision, and durability. The expertise involved in its manufacture, combined with the reputation and reliability of authoritative manufacturers, ensures that clients receive products that meet their specific needs and exceed their expectations. With its wide array of applications and the assurance of quality and performance, custom welded wire mesh continues to be a trusted solution for industry professionals worldwide.

The precision involved in crafting custom welded wire mesh cannot be overstated. Advanced welding techniques, such as automated welding processes, enhance the accuracy and consistency of the mesh. This results in uniform cross-sectional strength, which is critical for applications where even distribution of load is necessary. Whether the mesh is used in creating concrete slabs, fencing, or animal enclosures, the precision of the welds ensures maximum safety and efficacy. Case studies across various industries underscore the importance of using high-quality custom welded wire mesh. In the agricultural sector, for example, custom mesh has been utilized to create enclosures that protect livestock while providing ventilation and visibility. This not only safeguards the animals but also simplifies farm management practices. Construction projects often demand custom welded wire mesh for reinforcement purposes. One notable example is its use in road construction, where the mesh helps distribute stress and prevent cracking. The use of customized solutions allows engineers to address specific challenges unique to each project site, enhancing the lifespan and safety of infrastructure. In the automotive industry, custom welded wire mesh finds applications in vehicle manufacturing, particularly in creating sturdy, lightweight components that contribute to fuel efficiency. The customization ensures that each mesh component fits perfectly and performs under demanding conditions. In conclusion, custom welded wire mesh remains a cornerstone in various fields due to its adaptability, precision, and durability. The expertise involved in its manufacture, combined with the reputation and reliability of authoritative manufacturers, ensures that clients receive products that meet their specific needs and exceed their expectations. With its wide array of applications and the assurance of quality and performance, custom welded wire mesh continues to be a trusted solution for industry professionals worldwide.

Next:

Latest news

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025