-

+86 15030157877

-

sales@galvanizedmetalmesh.com

sty . 09, 2025 11:37 Back to list

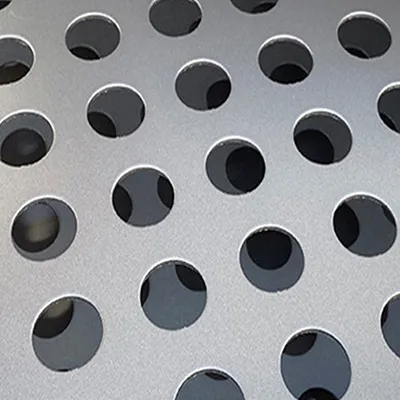

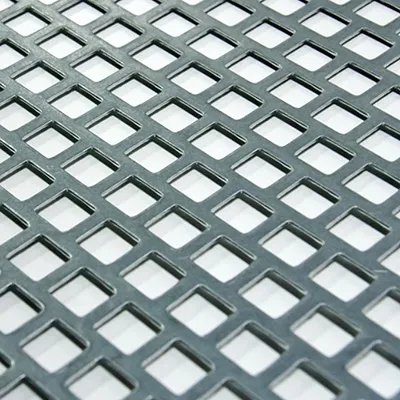

metal stainless steel perforated metal mesh

Metal mesh is revolutionizing various industries, offering a versatile solution that expertly balances elegance with functionality. This innovative material, crafted from an intricate web of metallic wires, is gaining momentum in sectors such as architecture, design, and industrial manufacturing. Having personally explored its applications across these domains, I can attest to its transformative power.

In industrial settings, metal meshes play a crucial role in filtration and sieving processes, especially in the purification of water and air. Having worked with an engineering firm, I've seen firsthand how industrial-grade metal meshes can withstand high-pressure environments while maintaining optimal filtration precision. Their adaptability allows for customization in mesh size and material, ensuring compatibility with specific industrial needs. For small startups to large manufacturing facilities, these meshes are indispensable. Trust in metal mesh solutions is grounded in their proven performance across these various sectors. Manufacturers often adhere to stringent quality standards, ensuring consistent reliability and safety. In fact, the meshes I’ve worked with are often certified by industrial standards organizations, assuring both clients and myself of their safety and efficacy in demanding applications. With expertise comes the awareness of sustainability, and metal mesh doesn’t disappoint. It is predominantly recyclable, with a high reuse value that aligns with the growing demand for eco-friendly materials. The recycling processes I've reviewed maintain the material's integrity, making it a favored choice among environmentally-conscious businesses. To conclude, metal mesh is a material of our times, blending art with practicality. Its applications are as wide-ranging as they are excellent, whether for aesthetic enhancements, durability in construction, or reliability in industrial use. From my extensive experience, should your project need a solution that offers design versatility alongside structural integrity, few options rival the innovative potential of metal mesh.

In industrial settings, metal meshes play a crucial role in filtration and sieving processes, especially in the purification of water and air. Having worked with an engineering firm, I've seen firsthand how industrial-grade metal meshes can withstand high-pressure environments while maintaining optimal filtration precision. Their adaptability allows for customization in mesh size and material, ensuring compatibility with specific industrial needs. For small startups to large manufacturing facilities, these meshes are indispensable. Trust in metal mesh solutions is grounded in their proven performance across these various sectors. Manufacturers often adhere to stringent quality standards, ensuring consistent reliability and safety. In fact, the meshes I’ve worked with are often certified by industrial standards organizations, assuring both clients and myself of their safety and efficacy in demanding applications. With expertise comes the awareness of sustainability, and metal mesh doesn’t disappoint. It is predominantly recyclable, with a high reuse value that aligns with the growing demand for eco-friendly materials. The recycling processes I've reviewed maintain the material's integrity, making it a favored choice among environmentally-conscious businesses. To conclude, metal mesh is a material of our times, blending art with practicality. Its applications are as wide-ranging as they are excellent, whether for aesthetic enhancements, durability in construction, or reliability in industrial use. From my extensive experience, should your project need a solution that offers design versatility alongside structural integrity, few options rival the innovative potential of metal mesh.

Next:

Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025