-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ago . 29, 2025 02:00 Back to list

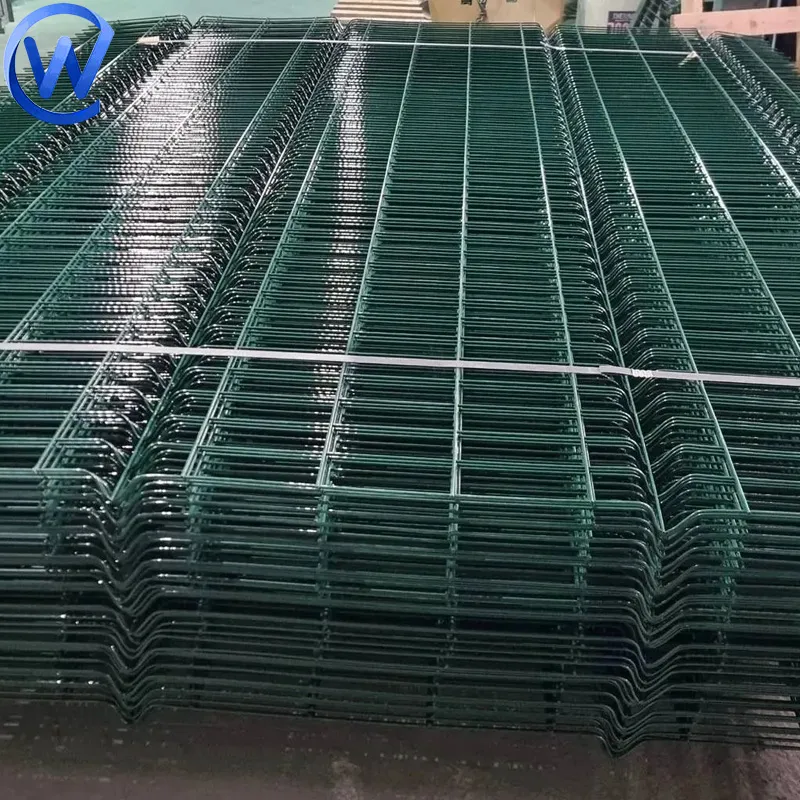

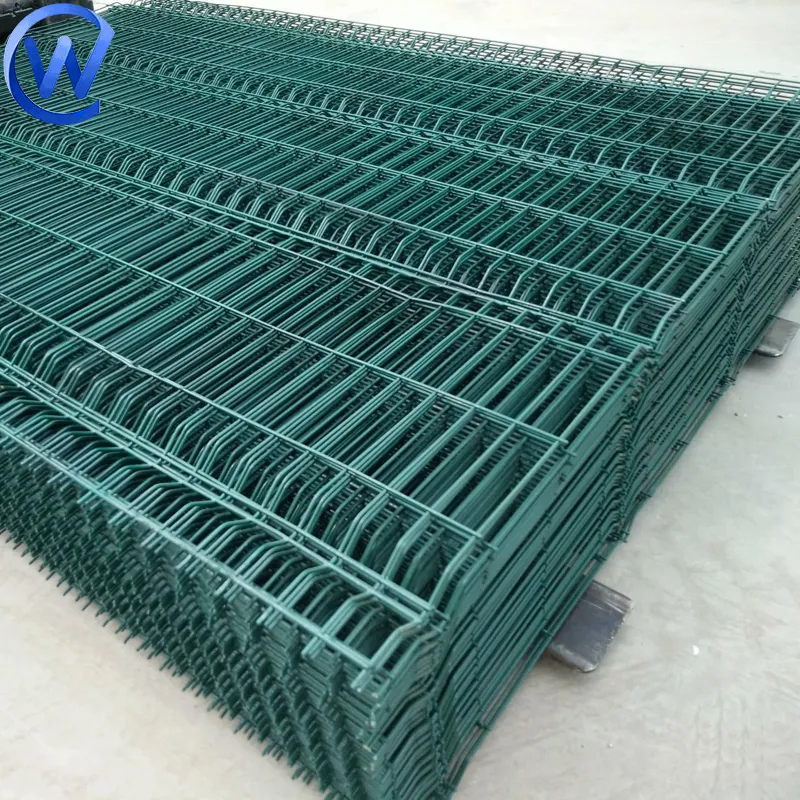

3D Curved Welded Wire Mesh Fence | Secure & Durable Panels

Introduction to Advanced Perimeter Security Solutions

In modern infrastructure and industrial applications, the demand for robust, aesthetically pleasing, and highly secure perimeter fencing solutions is continuously growing. Among the innovations addressing this need, the 3D Curved Welded Wire Mesh Fence stands out. This advanced fencing system combines strength, durability, and a distinctive curved design to offer superior security and visual appeal. This comprehensive guide delves into its technical specifications, manufacturing processes, diverse applications, and inherent advantages, providing B2B decision-makers with the insights needed to make informed procurement choices.

Industry Trends and Market Dynamics in Perimeter Security

The global perimeter security market is experiencing significant growth, driven by increasing geopolitical tensions, rising vandalism rates, and the critical need to protect high-value assets and critical infrastructure. According to a report by MarketsandMarkets, the perimeter security market size is projected to grow from USD 22.5 billion in 2022 to USD 34.6 billion by 2027, at a Compound Annual Growth Rate (CAGR) of 9.0%. Key trends influencing this growth include the adoption of advanced sensor technologies, integrated security systems, and an elevated focus on physical barriers that offer both deterrence and resilience. The demand for aesthetically integrated solutions that complement urban and industrial landscapes without compromising security is also a major driver. 3D Curved Welded Wire Mesh Fence systems align perfectly with these trends, offering a blend of high security, durability, and modern design that traditional flat mesh fences cannot match. Emphasis on environmental sustainability also drives demand for long-lifecycle products requiring minimal maintenance, which this fencing type provides through superior coatings.

Detailed Manufacturing Process of 3D Curved Welded Wire Mesh Fence

The production of a 3D Curved Welded Wire Mesh Fence involves a precise, multi-stage manufacturing process designed to ensure structural integrity, corrosion resistance, and aesthetic appeal. Adherence to international standards such as ISO 9001 for quality management is paramount throughout.

1. Material Selection and Preparation

High-quality steel wire, typically low-carbon steel or galvanized steel, is selected. For enhanced durability, options like stainless steel (e.g., AISI 304, 316) are also available. The wire diameter is a critical parameter, influencing the fence's rigidity and security level. Common diameters range from 3.0mm to 6.0mm.

2. Wire Straightening and Cutting

Raw wire coils are fed into an automatic straightening and cutting machine, ensuring precise lengths required for the mesh panel dimensions. This stage sets the foundation for uniform mesh construction.

3. Automated Welding

Utilizing state-of-the-art automated welding machines, the straightened wires are resistance-welded at their intersections to form rigid mesh panels. The welding parameters (current, pressure, time) are carefully controlled to ensure strong, consistent weld points, preventing panel deformation and enhancing structural stability. The mesh aperture (e.g., 50x200mm, 50x100mm) is determined at this stage.

4. 3D Bending (Curving)

After welding, the flat mesh panels undergo a specialized CNC bending process. Hydraulic bending machines are used to create the characteristic longitudinal V-shaped curves. These curves, typically 2-4 per panel depending on height, are crucial for increasing the panel's rigidity, anti-climb properties, and aesthetic appeal. The precision of CNC machining ensures uniform bending radius and depth across all panels.

5. Surface Treatment

This is a critical stage for longevity and corrosion resistance. Common surface treatments include:

- Hot-Dip Galvanization: Panels are immersed in molten zinc (typically 450°C), creating a metallurgical bond and a thick, highly durable zinc coating (e.g., 60-80 g/m² or more) that provides sacrificial corrosion protection. This meets standards like ASTM A123/A123M.

- Electro-Galvanization: A thinner zinc coating is applied electrolytically, offering moderate corrosion resistance.

- Powder Coating: After galvanization (for duplex protection) or direct application, electrostatic powder (e.g., polyester, epoxy) is applied and then heat-cured. This provides excellent UV resistance, a wide range of color options (e.g., RAL colors), and an additional layer of corrosion and abrasion resistance. Typical coating thickness is 80-120 microns.

- PVC Coating: A durable plastic coating applied over galvanized steel, offering superior protection against harsh environments and enhancing aesthetics.

6. Quality Control and Testing

Throughout the process, rigorous quality control checks are performed. This includes:

- Material Composition Analysis: Ensuring wire meets specified alloy standards.

- Weld Strength Testing: Destructive tests to verify weld integrity.

- Dimensional Accuracy: Checking mesh aperture, panel dimensions, and curve consistency against ANSI/ASTM specifications.

- Coating Thickness and Adhesion Tests: Using magnetic or eddy current gauges and cross-hatch tests to ensure coatings meet standards (e.g., EN ISO 1461 for galvanization, ASTM D3359 for adhesion).

- Salt Spray Testing: Accelerated corrosion tests (e.g., according to ASTM B117) to predict long-term performance in corrosive environments.

This meticulous process ensures that each 3D Curved Welded Wire Mesh Fence panel delivers optimal performance and a service life typically ranging from 15 to 25 years, depending on the coating and environmental conditions.

Technical Specifications and Parameters

Understanding the technical parameters of a 3D Curved Welded Wire Mesh Fence is crucial for project planning and ensuring compatibility with specific security and environmental requirements.

Key Product Specifications

Technical Advantages in Perimeter Security

The unique design and robust construction of the 3D Curved Welded Wire Mesh Fence offer several distinct technical advantages, making it a preferred choice for demanding applications.

- Enhanced Rigidity and Anti-Climb Properties: The longitudinal curves (crimps or V-bends) significantly increase the panel's resistance to bending and impact. This structural reinforcement also makes it difficult for intruders to climb, as there are no horizontal bars for footholds, and the rigid V-profile deters scaling.

- Superior Corrosion Resistance: Through multi-layer surface treatments like hot-dip galvanization followed by polyester powder coating (a duplex system), the fence achieves exceptional resistance to environmental degradation, UV radiation, and chemical exposure. This extends its service life significantly, reducing total cost of ownership.

- Aesthetic Integration: The 3D curved profile lends a modern, sleek appearance that can enhance the visual appeal of a property, a crucial factor for commercial, residential, and public sector projects. Available in various RAL colors, it can be seamlessly integrated with existing architectural styles.

- Vandalism and Tamper Resistance: The robust welded mesh structure with small apertures (e.g., 50x200mm) makes it resistant to cutting tools, while the secure post-and-panel attachment system (using specialized clips and bolts) minimizes tampering.

- Low Maintenance Requirements: The durable coatings and inherent strength minimize the need for frequent repairs or repainting, translating into lower operational costs over its extensive service life.

- Ease of Installation: Despite its robustness, the modular design allows for relatively straightforward installation, reducing labor costs and project timelines. Panels are typically pre-fabricated, requiring only assembly on site.

For industries demanding stringent security and long-term reliability, these technical advantages translate directly into enhanced asset protection and reduced operational overhead.

Diverse Application Scenarios

The versatility of the 3D Curved Welded Wire Mesh Fence allows for its deployment across a broad spectrum of industries and applications, providing effective perimeter security tailored to specific operational needs.

- Industrial Facilities: Securing factories, warehouses, logistics centers, and manufacturing plants where asset protection and access control are critical. The robust construction deters intrusion and defines clear boundaries.

- Commercial Properties: Enhancing the security of office parks, retail complexes, and corporate campuses. Its aesthetic appeal integrates well with modern commercial architecture.

- Public Infrastructure: Protecting airports, railway stations, ports, power substations, water treatment plants, and telecommunication sites from unauthorized access and sabotage. Its resilience against environmental factors ensures long-term reliability in critical national infrastructure.

- Educational Institutions: Providing secure perimeters for schools, colleges, and universities, ensuring student safety while maintaining an open, welcoming campus environment.

- Residential Communities: Delimiting and securing residential estates, apartment complexes, and private properties, offering both privacy and protection.

- Military and Government Sites: For applications requiring robust security, enhanced versions with smaller mesh apertures or additional security toppings can be integrated.

- Sports and Recreational Facilities: Fencing sports fields, tennis courts, parks, and playgrounds, offering safety, boundary definition, and ball containment.

Advantages in Specific Industries:

- Petrochemical and Metallurgy: The superior corrosion resistance from duplex coatings is critical in environments exposed to aggressive chemicals or high temperatures, ensuring long service life and reduced replacement costs.

- Water Supply & Drainage: Protecting water treatment plants and pumping stations, where security against vandalism and robust performance in humid, often corrosive, environments is essential.

- Energy Sector: Safeguarding solar farms, wind power stations, and power transmission sites from theft and sabotage, where wide perimeters need cost-effective yet strong barriers.

Vendor Comparison and Selection Criteria

Choosing the right supplier for a 3D Curved Welded Wire Mesh Fence is as crucial as the product itself. B2B purchasers should evaluate vendors based on a comprehensive set of criteria, extending beyond mere price.

Key Vendor Evaluation Metrics:

Choosing a vendor with a proven track record, stringent quality control, and robust support infrastructure is paramount for ensuring the long-term success and security of your projects involving 3D Curved Welded Wire Mesh Fence.

Customized Solutions and Enhanced Security Options

While standard configurations of 3D Curved Welded Wire Mesh Fence meet many requirements, critical infrastructure and high-security zones often demand bespoke solutions. Leading manufacturers offer extensive customization capabilities to address unique project specifications.

- Panel Dimensions and Wire Gauges: Tailored heights, widths, and choice of wire diameters (e.g., from 3.0mm to 6.0mm for increased rigidity and cut resistance) to match specific security threats and site topography.

- Mesh Aperture Variations: Smaller mesh openings (e.g., 25x75mm, 12.7x76.2mm - "358 mesh" style) to prevent hand or foot holds, making climbing virtually impossible and resisting most cutting tools.

- Enhanced Coating Systems: Specialized multi-layer coating systems (e.g., heavy galvanization + marine-grade powder coating) for extreme corrosive environments, such as coastal areas or industrial zones with chemical emissions.

- Integrated Security Features:

- Razor Wire/Barbed Wire Toppings: Installation of concertina or straight-line razor wire along the top for increased deterrence.

- CCTV and Sensor Integration: Posts designed to accommodate mounting brackets for security cameras, infrared sensors, or fiber optic intrusion detection systems.

- Access Control Gates: Matching swing gates or sliding gates, fabricated with the same mesh panels and finishes, often integrated with automated access control systems.

- Post Design and Foundation: Custom post lengths, gauges, and fixing methods (e.g., concrete-in, base-plated for surface mounting) to suit varying ground conditions and structural load requirements.

Collaborating with an experienced manufacturer for customized 3D Curved Welded Wire Mesh Fence solutions ensures optimal security performance, compliance with site-specific regulations, and seamless integration with existing infrastructure.

Application Case Studies and Customer Feedback

Real-world deployments demonstrate the effectiveness and versatility of the 3D Curved Welded Wire Mesh Fence in various demanding environments.

Case Study 1: High-Security Data Center Perimeter

A leading global technology company required a robust and aesthetically modern perimeter solution for its new data center in a bustling urban area. The solution involved a 2.4-meter high 3D Curved Welded Wire Mesh Fence with a 5.0mm wire diameter and 50x100mm mesh aperture, hot-dip galvanized and then powder-coated in a dark grey (RAL 7016) to blend with the architectural design. The V-bends provided significant anti-climb deterrence, while the small mesh aperture made cutting difficult. Integrated CCTV cameras were mounted directly onto the custom-designed posts, ensuring comprehensive surveillance. The client reported enhanced security, minimal maintenance, and positive feedback on the fence's modern appearance.

Case Study 2: Industrial Park in a Coastal Region

An industrial park located near a coastal environment faced severe corrosion challenges with its existing fencing. Our solution involved installing 1.8-meter high 3D Curved Welded Wire Mesh Fence panels manufactured from high-grade low-carbon steel, subjected to a double layer of protection: a heavy hot-dip galvanization (minimum 80 g/m² zinc coating) followed by a specialized marine-grade polyester powder coating. This duplex system significantly extended the fence's service life, offering superior resistance to salt spray and humidity. The project lead remarked, "The previous fence failed in under five years. With this new system, we anticipate at least 20 years of maintenance-free operation, a critical factor for our long-term operational budget."

Customer Feedback Highlights:

- "The installation process was surprisingly efficient, and the modular design really sped up project completion." - Project Manager, Logistics Hub

- "We've seen a measurable reduction in unauthorized access attempts since upgrading to the 3D curved mesh. The visual deterrent alone is very effective." - Security Director, Utility Company

- "The aesthetics are a major plus for our corporate campus. It provides robust security without looking imposing or industrial." - Facilities Manager, Tech Campus

Trustworthiness: FAQs, Lead Time, Warranty, & Support

Building trust with B2B clients requires transparency, clear commitments, and reliable support. Here’s what you can expect when partnering with us for your 3D Curved Welded Wire Mesh Fence needs.

Frequently Asked Questions (FAQs)

- What makes 3D curved mesh superior to flat welded mesh?

The 3D curves provide significantly increased rigidity and strength, making the fence more resistant to impact, bending, and cutting. They also enhance anti-climb properties and offer a more modern aesthetic. - What are the standard color options?

While black (RAL 9005), green (RAL 6005), and grey (RAL 7016) are standard, we offer a full range of RAL colors for powder coating to match specific project requirements. - Can the fence be installed on uneven terrain?

Yes, the modular design and various post lengths allow for adaptation to sloping or uneven terrain. Customized panel sizes can also be manufactured for complex topography. - What is the typical lifespan of the fence?

With our standard hot-dip galvanized and powder-coated finish, the expected service life is 15-25 years, depending on environmental conditions and maintenance. For harsher environments, specialized coatings can extend this further. - Are gates available to match the fencing?

Absolutely. We supply custom-fabricated pedestrian gates, single-swing gates, double-swing gates, and sliding gates, all designed to seamlessly integrate with the 3D Curved Welded Wire Mesh Fence system, using the same materials and finishes.

Lead Time and Fulfillment

Standard orders for 3D Curved Welded Wire Mesh Fence typically have a lead time of 2-4 weeks for manufacturing, followed by an additional 1-3 weeks for shipping, depending on the destination and logistics method (sea freight, air freight). Expedited manufacturing and shipping options are available for urgent projects upon request and are quoted based on specific requirements. We maintain a robust supply chain and efficient production scheduling to ensure timely delivery for all our clients.

Warranty Commitments

We stand behind the quality of our products. Our 3D Curved Welded Wire Mesh Fence systems come with a comprehensive warranty:

- 10-Year Anti-Corrosion Warranty: For hot-dip galvanized and powder-coated products, guaranteeing protection against rust and coating degradation under normal environmental conditions.

- 5-Year Workmanship Warranty: Covering any defects in manufacturing or welding.

Specific warranty terms and conditions are provided with each quotation and order confirmation.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We offer dedicated customer support and after-sales service to ensure the long-term success of your fencing project:

- Technical Consultation: Expert advice during project planning, material selection, and system design.

- Installation Guidance: Detailed installation manuals and remote technical assistance for your installation teams.

- Spare Parts Availability: Ready supply of replacement components (clips, caps, posts) to facilitate repairs or expansions.

- Responsive Communication: A dedicated client service team accessible via email and phone to address any queries or concerns promptly.

Conclusion: Elevating Perimeter Security Standards

The 3D Curved Welded Wire Mesh Fence represents a pinnacle in modern perimeter security, offering an unparalleled blend of strength, durability, aesthetic appeal, and adaptability. From its meticulously controlled manufacturing process, adhering to international standards, to its diverse applications across critical industries, this fencing solution provides a robust and reliable barrier against intrusion and environmental degradation. Its technical advantages, coupled with extensive customization options and unwavering vendor support, position it as the preferred choice for B2B decision-makers and engineers seeking advanced security infrastructure. Investing in this proven technology ensures not only the protection of valuable assets but also contributes to the long-term operational efficiency and visual integrity of any facility.

References

- MarketsandMarkets. "Perimeter Security Market - Global Forecast to 2027." Published March 2022.

- ASTM International. "A123/A123M - 17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products."

- EN ISO 1461:2009. "Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods."

- ASTM International. "B117 - 19: Standard Practice for Operating Salt Spray (Fog) Apparatus."

- ASTM International. "D3359 - 17: Standard Test Methods for Measuring Adhesion by Tape Test."

This is the last article

-

3D Curved Welded Wire Mesh Fence | Secure & Durable Panels

NewsAug.29,2025

-

Stainless Steel Angle Factories: Premium Quality & Custom Solutions

NewsAug.28,2025

-

Heavy-Duty Stackable Storage Cages for Efficient Warehouse Storage

NewsAug.27,2025

-

Stainless Steel Wire Mesh: Durable & Corrosion-Resistant Rolls

NewsAug.26,2025

-

Durable Fences: Garden, Pool, Metal & Security Solutions

NewsAug.25,2025

-

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

NewsAug.24,2025