-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 05, 2024 23:43 Back to list

Coarse Wire Mesh Production Facility and Its Applications in Various Industries

Exploring the World of Coarse Wire Mesh Factories

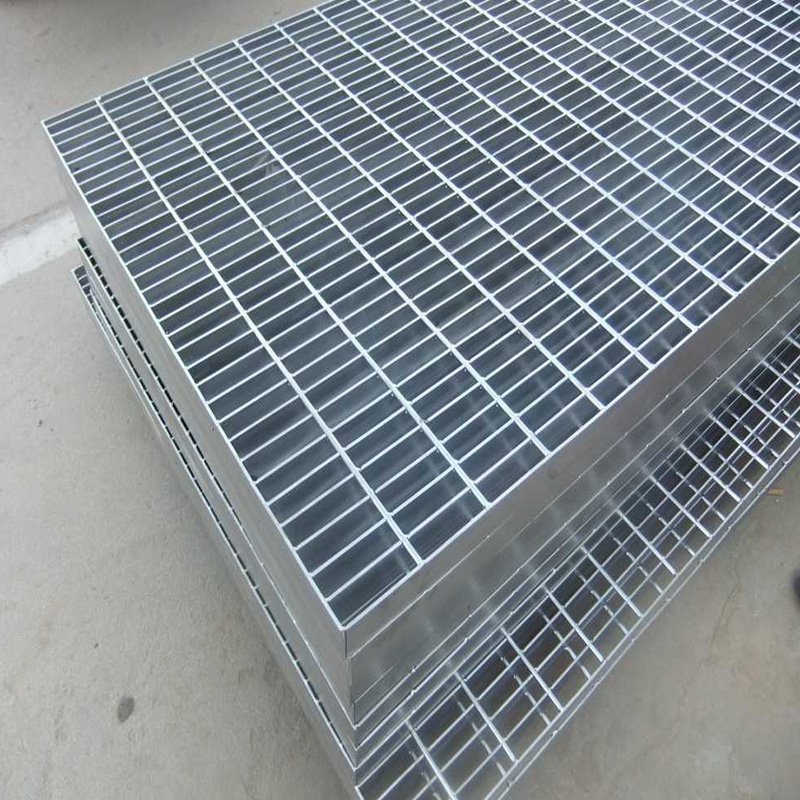

Coarse wire mesh is an essential material used in various industries, ranging from construction to filtration systems. It consists of interwoven wires that create a grid-like structure, allowing for a range of applications due to its strength, durability, and versatility. This article will delve into the operations of a coarse wire mesh factory, shedding light on its manufacturing processes, types of products, and industry significance.

The Manufacturing Process

The production of coarse wire mesh begins with the selection of raw materials, typically high-quality steel or stainless steel wire, chosen for their tensile strength and corrosion resistance. The manufacturing process can be broken down into several key stages

1. Wire Drawing The first step involves drawing the wire through a series of dies to reduce the thickness and increase its length. This process is crucial as it ensures that the wire meets the specific diameter required for different mesh types.

2. Woven Formation Once the wire is prepared, it undergoes the weaving process. Using advanced weaving machines, the wire is interlaced to create the mesh. Various patterns can be used, including plain weave, twill weave, and dutch weave, each offering distinct characteristics suited for specific applications.

3. Cutting and Finishing After weaving, the coarse wire mesh is cut to the desired size. Finishing processes may include edge treatment, coating for rust resistance, and quality inspections to ensure that each piece meets industry standards.

Types of Coarse Wire Mesh

Coarse wire mesh is categorized based on the size of the openings, the diameter of the wire, and the weaving technique employed. Some common types include

coarse wire mesh factory

- Screen Mesh Often used in construction and mining industries, this type features larger openings suited for gravel and aggregate screening.

- Filter Mesh With smaller openings, this mesh is ideal for applications in wastewater treatment and industrial filtration.

- Railing and Fencing Mesh Designed for structural support and safety, this coarse mesh is commonly used in fencing and barricades.

- Animal Control and Habitat Enclosures Coarse wire mesh is frequently employed in agricultural settings to protect crops and enclose livestock.

Industry Significance

The coarse wire mesh industry plays a vital role in several sectors. In construction, the mesh is utilized for reinforcing concrete and creating barriers that ensure the safety of workers and the integrity of structures. In the automotive and aerospace industries, filter mesh helps guarantee that contaminants are removed from fluids, enhancing product safety and performance.

Additionally, the agricultural sector relies heavily on coarse wire mesh for pest control and animal husbandry. The mesh provides a physical barrier against wildlife, protecting crops and livestock from predation and disease.

The versatility of coarse wire mesh continues to expand as technology advances. Innovations in weaving techniques and material science allow for the development of specialized products that meet ever-evolving industrial needs. As industries increasingly prioritize sustainability, manufacturers are also exploring eco-friendly practices and materials to reduce their environmental impact.

Conclusion

Coarse wire mesh factories are hubs of innovation and productivity, contributing significantly to various sectors worldwide. The meticulous manufacturing processes, diverse range of products, and their critical role in industrial applications highlight the importance of this industry. As technology continues to evolve, the potential for coarse wire mesh products will likely grow, paving the way for new uses and applications in the future. Whether for construction, filtration, or agricultural purposes, coarse wire mesh remains a fundamental component of modern infrastructure and industrial processes.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025