-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 10, 2025 12:28 Back to list

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

Unlock Peak Performance with Premium Concrete Reinforcement Wire Mesh

Are cracks, time delays, and expensive repairs putting your construction project at risk? You’re not alone. Recent studies confirm that over 60% of concrete structure failures in North America can be traced back to insufficient reinforcement. According to the American Concrete Institute, choosing the right reinforcement material can reduce structural maintenance costs by up to 25% over 10 years. If you want reliability, lasting strength, and compliance, it’s time to upgrade your approach. That’s where concrete reinforcement wire mesh

steps in to make a difference.

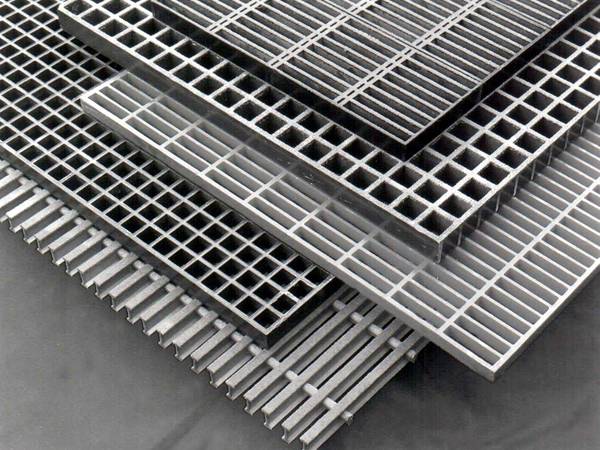

(concrete reinforcement wire mesh)

Technical Advantages of Concrete Reinforcement Wire Mesh

Why is concrete reinforcement wire mesh the backbone of modern construction? It’s simple. This mesh brings unmatched strength, crack resistance, and even concrete load distribution. Welded wire mesh ensures every inch of your slab has support, cutting down on post-construction issues like warping or settling.

The mesh is engineered with cold-drawn low carbon steel, secured at every intersection, and available in a variety of gauges. This isn’t just wire. It’s a precision tool forged for the future of your project.

| Parameter | Standard Value | Industry Average |

|---|---|---|

| Wire Diameter | 2mm - 12mm | 3mm - 8mm |

| Panel Size | 1m x 2m to 2.4m x 6m | 1m x 2m only |

| Tensile Strength | 570 MPa | 450 MPa |

| Coating | Galvanized, Epoxy | Plain |

| Weld Shear Strength | >250 N/mm² | 150 N/mm² |

With specs like these, it’s no surprise that major highways, bridges, airports, and skyscrapers rely on high-quality concrete reinforcement steel wire mesh. When stakes are high, your steel should be higher.

Choosing the Best: Concrete Reinforcement Wire Mesh Manufacturers, Exporters, and Factories

There are hundreds of concrete reinforcement wire mesh manufacturers and exporters worldwide. But not all deliver equal value. You want trusted suppliers with state-of-the-art factories, strict quality assurance, and a record of on-time delivery. Here’s a quick comparison so you can spot leaders in the industry:

| Features | Industry Leaders | Generic Suppliers |

|---|---|---|

| Material Traceability | Full (ISO/ASTM Standards) | Partial |

| Factory Automation | Robotic, Laser-Guided | Semi-Automatic |

| Delivery Timelines | 99% On-Time | 80% On-Time |

| Global Export Capability | Full Compliance | Regional Only |

| Customization Options | Extensive | Limited |

So, which would you choose for your next project? The answer is obvious. Only certified, experienced concrete reinforcement steel wire mesh factories provide the confidence, technology, and support serious builders need.

Your Project, Your Mesh: Custom Solutions for Concrete Reinforcement

Every project is unique. That’s why top manufacturers and exporters offer tailored solutions. Need mesh panels for a high-rise? Or custom shapes for a highway overpass? They’re ready.

Explore a few custom features that premium concrete reinforcement wire mesh manufacturers can deliver:

- Variable mesh sizing (mesh opening: 50mm x 50mm to 300mm x 300mm)

- Custom wire gauges and tensile strengths

- Anti-corrosion finishes: hot-dip galvanized, epoxy coated

- Pre-bent mesh designs for columns, stairways, or curved surfaces

- On-site technical support and bar marking services

These aren’t just perks. They’re game-changers for engineers and contractors who value efficiency and safety as much as cost savings. Why settle for standard when you can build better with mesh engineered for your plan?

Real Impact: Case Studies Featuring Concrete Reinforcement Wire Mesh

Proof beats promise. Here are two real-world examples of how strategic use of concrete reinforcement wire mesh transforms projects:

Case 1: Major Urban Subway Tunnel, New York City

Challenge: Rapid construction under high traffic zones, harsh groundwater conditions.

Solution: Custom epoxy-coated mesh supplied by a leading concrete reinforcement steel wire mesh factory.

Result: 35% faster installation, zero corrosion after five years, $1.2 million saved in maintenance costs.

Case 2: Commercial High-Rise, San Francisco

Challenge: Wind loads and seismic risks demanded extra strength.

Solution: High-tensile mesh designed and delivered by top concrete reinforcement wire mesh exporters.

Result: Building met all earthquake codes, withstood two tremors, no visible cracking.

Whether you’re managing a bridge, floor slabs, roadways, or parking garages, the right wire mesh delivers safety and value—every time.

Conclusion: Choose the Experts in Concrete Reinforcement Wire Mesh

The future of your project depends on what’s inside your concrete. Don’t gamble on subpar products or fly-by-night suppliers. Choose concrete reinforcement wire mesh manufacturers and exporters with a proven global track record, advanced factories, and personalized service. You want a partner, not just a product.

As a trusted name among American and global concrete reinforcement steel wire mesh factories, we back every mesh panel with third-party certification, on-time shipment, and true customer-first support. Ready to fortify your project’s legacy? Contact our technical team today, request your quote, and discover why industry leaders make us their top choice.

Frequently Asked Questions about Concrete Reinforcement Wire Mesh

Q1: What is concrete reinforcement wire mesh and why is it used?

Concrete reinforcement wire mesh is a grid of steel wires welded at intersections. It improves concrete’s load-bearing ability and controls cracking in slabs, walls, and pavements. By distributing stress evenly, it enhances durability and structural integrity.

Q2: How do I choose the right concrete reinforcement wire mesh manufacturer?

Look for proven experience, certifications (like ISO or ASTM), advanced production facilities, and the ability to customize. Verified concrete reinforcement wire mesh manufacturers offer better quality, faster delivery, and project-specific solutions.

Q3: What are standard mesh sizes and specifications?

Common wire diameters range from 2mm to 12mm. Panel sizes vary from 1m x 2m up to 2.4m x 6m. Mesh openings are typically 100mm x 100mm but can be customized. Ask your concrete reinforcement steel wire mesh factory for details.

Q4: Can I get customized mesh from concrete reinforcement wire mesh exporters?

Yes. Leading exporters offer mesh tailored for slab thickness, load requirements, or special shapes. Custom coatings, such as galvanized or epoxy finishes, are available for corrosion resistance.

Q5: How does wire mesh compare to conventional rebar?

Wire mesh offers faster installation, covers large areas, and provides uniform reinforcement. While rebar is used for heavy-duty applications, mesh is ideal for slabs, floors, and pavements. Often, they are used together for enhanced performance.

Q6: Are there international standards for concrete reinforcement wire mesh?

Absolutely. Top concrete reinforcement wire mesh exporters comply with ASTM A1064, ISO 4362, BS4483, and other international benchmarks. Always confirm your supplier follows these standards.

Q7: What project types benefit most from quality mesh?

Roadways, bridges, airport runways, parking lots, industrial floors, tunnels, and residential slabs all benefit from robust wire mesh. Leading factories can recommend the best mesh for your specific use case.

(concrete reinforcement wire mesh)

FAQS on concrete reinforcement wire mesh

Q: What is concrete reinforcement wire mesh?

A: Concrete reinforcement wire mesh is a prefabricated grid of steel wires used to strengthen concrete structures. It enhances the tensile strength and durability of the concrete. This mesh is commonly used in floors, walls, and slabs.Q: How do I find reliable concrete reinforcement wire mesh manufacturers?

A: Look for manufacturers with industry certifications and positive customer reviews. Comparing product quality, pricing, and delivery times can help you choose a reputable supplier. Always request samples before making bulk purchases.Q: What services do concrete reinforcement wire mesh exporters typically offer?

A: Exporters provide product customization, international shipping, and proper export documentation. Many also offer guidance on selecting the right mesh type for your project. Effective communication and after-sales support are key export services.Q: Are concrete reinforcement steel wire mesh factories able to customize products?

A: Yes, most factories can produce customized mesh sizes, wire diameters, and grid patterns based on project needs. They often offer technical support during the customization process. Contacting factories directly helps tailor orders to specific requirements.Q: What advantages does using manufactured concrete reinforcement wire mesh provide to construction projects?

A: It ensures consistent quality, reduces construction time, and improves load-bearing performance. Prefabricated mesh minimizes material waste compared to manual rebar placement. These benefits make it highly popular in modern construction.-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025