-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 11, 2024 14:59 Back to list

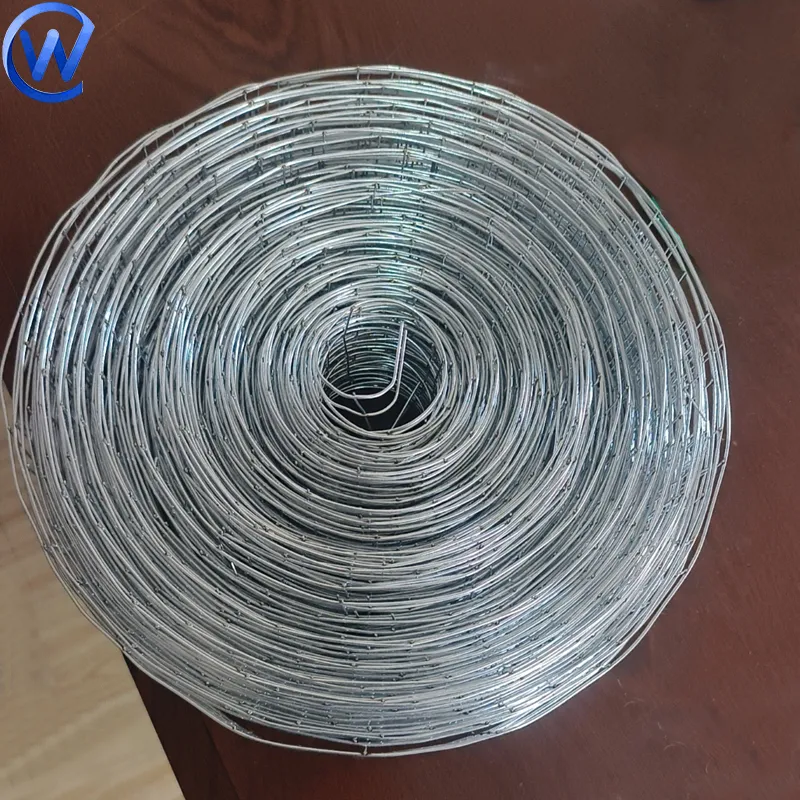

crimped woven wire mesh factories

The Importance of Crimped Woven Wire Mesh in Modern Industries

Crimped woven wire mesh is a versatile and essential material used across various industries, ranging from construction and mining to agriculture and food processing. Its unique design and functionality make it an invaluable asset for many applications. This article will explore the characteristics, manufacturing processes, and key benefits of crimped woven wire mesh produced by specialized factories.

Characteristics of Crimped Woven Wire Mesh

Crimped woven wire mesh is characterized by its distinctive crimped pattern, which is achieved by shaping the wire before weaving. This process increases the mesh's strength and durability while providing a more rigid structure. The wires are typically made from high-quality materials such as stainless steel, carbon steel, or aluminum, each selected for its specific properties, such as corrosion resistance and tensile strength.

The mesh's openings can be customized in size and shape, allowing it to cater to various filtration, screening, and reinforcement needs. Depending on the requirement, manufacturers can produce mesh with different gauges, ensuring that the safety and integrity of the applications are always maintained.

Manufacturing Process

The production of crimped woven wire mesh involves several steps. First, high-quality wire is sourced and prepared. The wire is then crimped to create the desired pattern, which enhances its mechanical properties. Once crimped, the wire is woven into the mesh using a loom, which intertwines the wires in a way that maximizes strength and stability.

Factories specializing in this product often utilize advanced technology and machinery to optimize the production process. Quality control measures are integrated at each stage to ensure that the finished product meets industry standards and client specifications.

crimped woven wire mesh factories

Applications Across Industries

Crimped woven wire mesh finds applications in various sectors. In the construction industry, it is commonly used for reinforcement in concrete structures, providing additional support and preventing cracks. In mining, it serves as an effective screening and filtering medium, separating materials of different sizes efficiently.

The agricultural sector also benefits from crimped woven wire mesh, particularly for fencing and enclosures. Its robust design protects livestock and crops from predators and prevents animals from straying. Moreover, in the food and beverage industry, this type of mesh is crucial for sorting and sifting, ensuring that products meet hygiene standards and specifications.

Benefits of Crimped Woven Wire Mesh

One of the primary benefits of crimped woven wire mesh is its strength and durability. The crimping process enhances the mesh's resistance to wear, tear, and environmental factors, making it suitable for both indoor and outdoor use. Additionally, the versatility of the mesh allows for customization based on specific project requirements, which is a significant advantage for industries with varying needs.

Moreover, crimped woven wire mesh is cost-effective. Its long lifespan and low maintenance requirements make it a wise investment for businesses looking to minimize operational costs. The ease of installation further contributes to its popularity, allowing companies to integrate it into existing systems without extensive modifications.

Conclusion

In conclusion, crimped woven wire mesh is a critical material used across multiple industries, providing strength, durability, and versatility. Factories specializing in its production ensure that high-quality standards are maintained throughout the manufacturing process. As industries continue to evolve, the importance of reliable and efficient materials like crimped woven wire mesh will only grow, making it a staple in modern applications. Whether for construction, mining, agriculture, or food processing, the contributions of crimped woven wire mesh are undeniable, positioning it as a cornerstone of industrial innovation.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025