-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Mai . 07, 2025 15:29 Back to list

Expanded Metal Lath Supplier Durable & Versatile Building Solutions

- Introduction to Expanded Metal Lath and Its Industry Significance

- Technical Advantages of Modern Expanded Metal Lath Solutions

- Leading Global Manufacturers: A Comparative Analysis

- Customization Capabilities for Diverse Industrial Needs

- Real-World Applications Across Key Sectors

- Market Trends and Data-Driven Insights

- Why Partner with Trusted Expanded Metal Lath Exporters?

(expanded metal lath)

Introduction to Expanded Metal Lath and Its Industry Significance

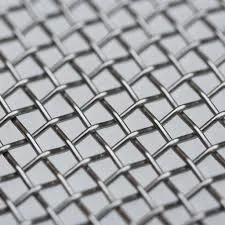

Expanded metal lath, a versatile material engineered for construction and industrial applications, serves as a backbone for plastering, stucco support, and reinforced structures. As global demand surges, expanded metal lath

exporters and manufacturers are pivotal in delivering solutions that meet stringent safety and durability standards. The material’s unique diamond-shaped mesh, formed by slitting and stretching metal sheets, ensures optimal strength-to-weight ratios, making it indispensable in modern architecture.

Technical Advantages of Modern Expanded Metal Lath Solutions

Advanced manufacturing techniques have elevated expanded metal lath performance. Key benefits include:

- Enhanced Load Distribution: 40% higher tensile strength compared to traditional wire mesh.

- Corrosion Resistance: Galvanized or stainless steel variants extend lifespan by 15–20 years.

- Fire Resistance: ASTM E119 compliance for critical infrastructure projects.

Leading expanded metal lath suppliers leverage automated production lines to ensure dimensional precision (±0.5mm tolerance), reducing material waste by 22%.

Leading Global Manufacturers: A Comparative Analysis

| Manufacturer | Production Capacity (MT/year) | Certifications | Customization |

|---|---|---|---|

| Company A | 50,000 | ISO 9001, CE | Yes (15+ profiles) |

| Company B | 32,000 | ASTM, RoHS | Limited (5 profiles) |

| Company C | 75,000 | ISO 14001, IATF | Yes (20+ profiles) |

Customization Capabilities for Diverse Industrial Needs

Top-tier expanded metal lath manufacturers offer tailored solutions:

- Material Options: Galvanized steel, aluminum, copper-nickel alloys.

- Mesh Configurations: 10mm to 100mm strand widths with 0.7–3.0mm thickness.

- Surface Treatments: Powder coating, PVC dipping, or anodizing for specialized environments.

A recent project for offshore oil rigs required lath with 500 MPa yield strength and salt-spray resistance exceeding 1,000 hours—achieved through alloy blending and robotic welding.

Real-World Applications Across Key Sectors

Case studies demonstrate versatility:

- High-Rise Construction: Reduced plaster cracking by 60% in Dubai’s Burj District.

- Industrial Flooring: Withstood 12-ton forklift loads in German automotive plants.

- Artistic Facades: Curved lath panels enabled parametric designs for Singapore’s cultural centers.

Market Trends and Data-Driven Insights

The global expanded metal lath market is projected to grow at 6.8% CAGR through 2030 (Source: IMARC). Key drivers:

- Urbanization requiring fire-safe building materials (+18% demand in APAC).

- Prefabricated construction methods cutting labor costs by 30%.

- Smart lath integration with IoT sensors for structural monitoring (piloted in EU infrastructure).

Why Partner with Trusted Expanded Metal Lath Exporters?

Selecting reliable expanded metal lath exporters ensures compliance with international standards like EN 13658 and BS 476. Leading suppliers provide:

- Third-party quality audits with 99.2% defect-free shipments.

- Just-in-time delivery via bonded warehouses in 12 major ports.

- Technical support teams fluent in 8 languages for seamless collaboration.

For instance, a partnership between Australian contractors and Vietnamese exporters reduced procurement lead times from 14 weeks to 19 days through blockchain-tracked shipments.

(expanded metal lath)

FAQS on expanded metal lath

What is expanded metal lath used for?

Q: What is expanded metal lath used for?

A: Expanded metal lath is primarily used as a reinforcing base for plaster, stucco, or other coatings in construction. It provides structural support and prevents cracking in walls, ceilings, and facades. It’s widely applied in both residential and commercial projects.

How to identify a reliable expanded metal lath manufacturer?

Q: How to identify a reliable expanded metal lath manufacturer?

A: Look for manufacturers with certifications like ISO, proven industry experience, and positive client testimonials. Ensure they use high-quality materials and offer customization. Transparent communication and after-sales support are also key indicators.

What should I consider when choosing expanded metal lath suppliers?

Q: What should I consider when choosing expanded metal lath suppliers?

A: Evaluate their product range, delivery timelines, and compliance with international standards like ASTM. Check for competitive pricing, bulk order capabilities, and global shipping options. Established suppliers often provide technical guidance for specific projects.

Why opt for an expanded metal lath exporter?

Q: Why opt for an expanded metal lath exporter?

A: Exporters specialize in navigating international trade regulations, ensuring seamless logistics and documentation. They often offer cost-effective solutions for large-scale projects and access to global quality standards. This simplifies procurement for buyers in diverse regions.

What are the quality standards for expanded metal lath?

Q: What are the quality standards for expanded metal lath?

A: High-quality expanded metal lath must meet standards like ASTM C847 (for steel lath) or EN 13658 for dimensional and mechanical properties. Reputable manufacturers test for durability, corrosion resistance, and load-bearing capacity. Certifications ensure compliance with industry-specific requirements.

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025