-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dez . 24, 2024 08:02 Back to list

Versatile Applications of Perforated Mesh in Modern Design and Manufacturing

The Versatility and Applications of Perforated Mesh

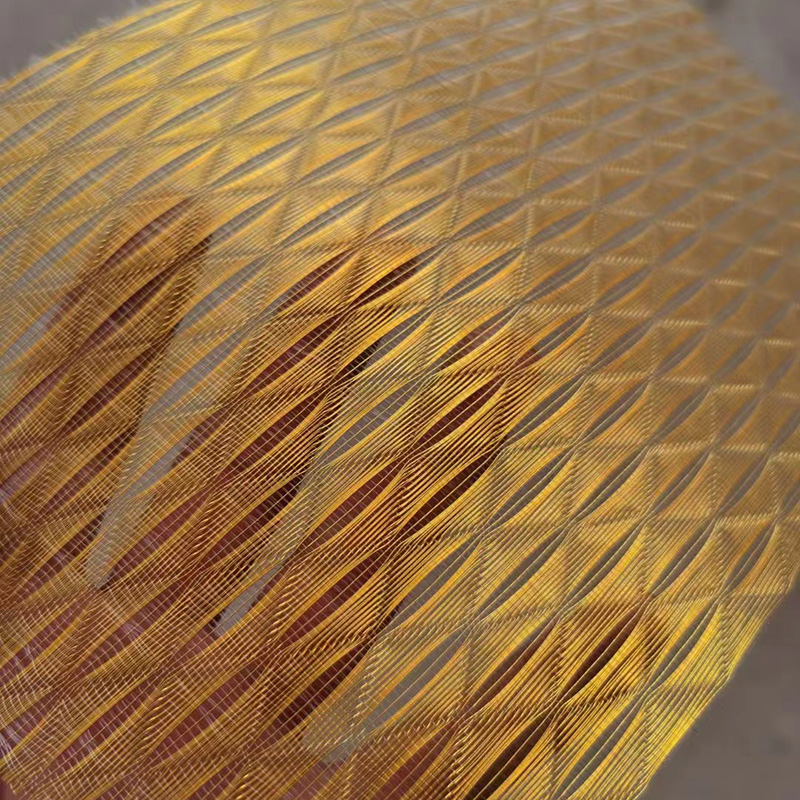

Perforated mesh is an innovative material that has gained significant traction across various industries due to its unique properties and functionalities. Characterized by its sheet-like design with a series of holes or perforations, this material is engineered to serve multiple purposes, ranging from aesthetic appeal to functional applications in industrial settings. This article explores the various benefits and applications of perforated mesh, highlighting its growing importance in modern manufacturing and design.

What is Perforated Mesh?

Perforated mesh is usually made from metal, plastic, or fiberglass materials. The perforation process involves creating a pattern of holes in a sheet, which can be tailored in size, shape, and spacing according to specific requirements. This process not only enhances the material’s structural strength but also reduces its weight, making it an ideal choice for different applications. The holes can be round, square, or even intricate designs, allowing for great flexibility in both functionality and aesthetics.

Benefits of Perforated Mesh

1. Lightweight and Durable One of the primary advantages of perforated mesh is its combination of lightweight properties with robust strength. The open design enables better airflow and drainage while maintaining the structural integrity of the material.

2. Versatile Applications Perforated mesh can be used in various sectors such as construction, automotive, filtration, and interior design. Its versatility allows it to be implemented in applications like ceilings, wall panels, architecture facades, and protective screens.

3. Aesthetic Appeal With customizable hole patterns and finishes, perforated mesh can enhance the visual aesthetics of a space. Designers leverage its unique appearance to create striking visuals in both commercial and residential settings.

4. Acoustic Properties Certain types of perforated mesh are designed to improve sound absorption in a space. This makes it an excellent choice for auditoriums, offices, and other environments where acoustics are a significant consideration.

perforated mesh

5. Sustainability Many perforated mesh products are made from recyclable materials, contributing to sustainability efforts. Furthermore, their lightweight nature often results in lower transportation costs and a reduced carbon footprint.

Applications of Perforated Mesh

1. Architecture and Construction In the construction industry, perforated mesh serves as a functional and aesthetic element. It can be used for facades, allowing sunlight to filter into buildings while minimizing glare. Its utility in safety and security applications is also notable, as it can provide visibility while still acting as a barrier.

2. Filtration Systems Perforated mesh is extensively used in filtration applications. Its precise hole sizes can effectively separate particles from liquids or gases, making it ideal for water treatment plants, HVAC systems, and industrial filtering processes.

3. Automotive Industry In automotive applications, perforated mesh is utilized for various components such as grilles, guards, and part enclosures. It helps prevent debris from entering sensitive areas while still allowing airflow.

4. Interior Design Perforated mesh is becoming increasingly popular in interior design. Its use in decorative panels, room dividers, and ceiling tiles offers a unique blend of style and functionality, allowing for the creation of dynamic spaces.

5. Public Transportation Train and bus stations often incorporate perforated mesh for applications such as windbreaks and noise barriers. These installations provide a practical solution to enhance commuter comfort and safety.

Conclusion

Perforated mesh represents a remarkable fusion of functionality and aesthetic potential, catering to diverse industries and applications. Its lightweight yet durable nature, coupled with customization options, makes it a go-to choice for designers and engineers alike. As industries continue to innovate, the role of perforated mesh is likely to expand, reinforcing its status as a vital material in contemporary manufacturing and design. The growing awareness of its benefits will ensure that perforated mesh remains an essential resource in future projects, contributing to efficient, sustainable, and visually appealing solutions in various settings.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025