-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 02, 2025 05:22 Back to list

perforated metal mesh sheet manufacturer

Understanding Perforated Metal Mesh Sheets A Key Element in Design and Functionality

In the world of industrial and architectural design, perforated metal mesh sheets have gained significant attention due to their versatility, functionality, and aesthetic appeal. These sheets are available in various materials, including steel, aluminum, and copper, and can be customized according to different specifications. As a manufacturer of perforated metal mesh sheets, understanding their various applications and properties is key to providing high-quality products that meet market demands.

What is Perforated Metal?

Perforated metal is created by punching holes into a solid sheet of metal, resulting in a mesh-like appearance. The holes can be arranged in patterns that are functional and visually appealing, depending on the intended use. This process of perforation can be tailored to a variety of shapes, sizes, and spacing, allowing manufacturers to create unique designs that suit diverse applications.

Applications of Perforated Metal Mesh Sheets

1. Architectural Elements One of the most common applications for perforated metal sheets is in architectural design. These sheets can be used for building facades, ceiling tiles, and privacy screens. Their ability to let light and air through while providing a level of sound attenuation makes them ideal for both interior and exterior design.

2. Industrial Applications In industrial settings, perforated metal mesh is crucial for functions such as filtration and ventilation. They are used in machinery guards, exhaust systems, and even grain storage bins, helping to maintain safety while allowing the necessary airflow.

3. Consumer Products Perforated metal sheets are increasingly found in consumer products, including home décor items, lighting fixtures, and furniture. Their aesthetic appeal allows designers to push creative boundaries, leading to unique products that can enhance any living space or workspace.

Benefits of Using Perforated Metal Mesh Sheets

perforated metal mesh sheet manufacturer

The advantages of perforated metal mesh sheets extend beyond their striking appearance. Here are some critical benefits that make them a preferred choice among designers and manufacturers

- Lightweight and Durable Depending on the base material used, perforated metal sheets are typically lightweight yet strong, allowing for easy handling and installation without compromising durability.

- Cost-Effective When compared to solid metal sheets, perforated versions can be more economical as they use less raw material while still providing comparable strength, making them a suitable choice for budget-conscious projects.

- Versatility The customizability of perforated metal means it can be tailored to fit a wide range of applications. Whether you need a specific size, pattern, or finish, manufacturers can provide solutions that meet exact specifications.

- Aesthetic Appeal With their diverse design possibilities, perforated metal mesh sheets can enhance the visual appeal of a project, adding depth, texture, and character to any space.

Choosing the Right Manufacturer

When selecting a manufacturer for perforated metal mesh sheets, it is essential to consider their experience, technology, and quality control processes. Look for manufacturers that offer a range of materials, hole patterns, and additional finishes. A reputable manufacturer will be able to provide guidance on the best options for your specific needs while ensuring that products meet all regulatory standards.

Conclusion

Perforated metal mesh sheets serve as a perfect blend of functionality and design. As a manufacturer in this field, understanding the various applications, benefits, and specifications of these sheets will enable you to meet the unique needs of your clients. Whether for industrial purposes or innovative architectural designs, perforated metal mesh sheets continue to play an integral role in modern design and engineering solutions.

-

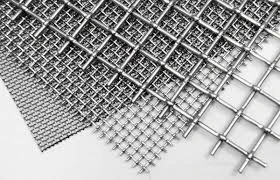

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025