-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dez . 28, 2024 14:54 Back to list

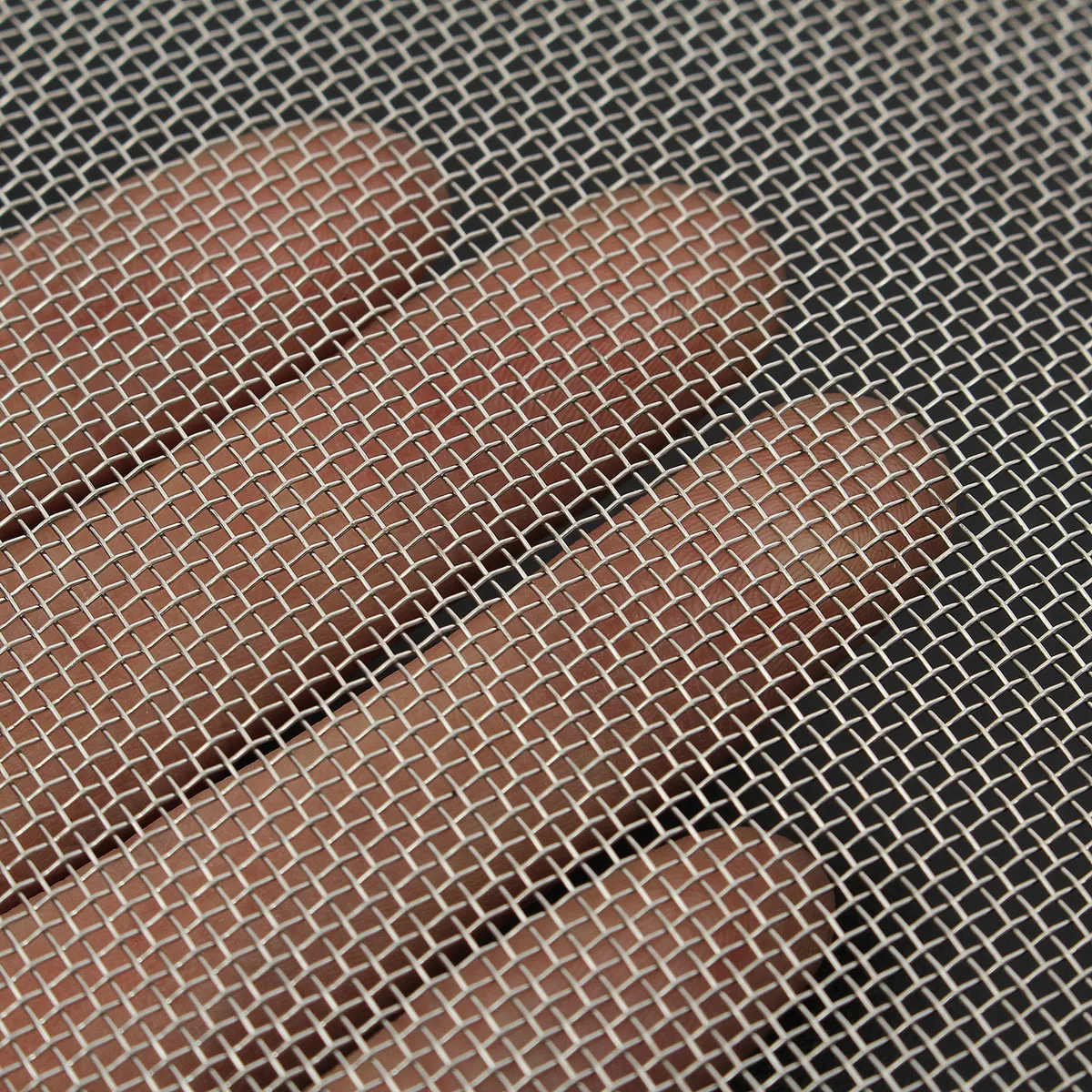

stainless wire mesh manufacturers

The Rising Demand for Stainless Wire Mesh Manufacturers

In recent years, the demand for stainless wire mesh has surged across various industries due to its exceptional durability, corrosion resistance, and versatility. As a result, stainless wire mesh manufacturers are playing a critical role in meeting the diverse needs of sectors such as construction, automotive, food processing, and pharmaceuticals. This article delves deeper into the importance of stainless wire mesh, the manufacturing process, and the factors that contribute to the growing market.

What is Stainless Wire Mesh?

Stainless wire mesh is a type of woven material made from stainless steel wires. Utilizing various mesh patterns, it serves multiple functions, including filtration, screening, and reinforcement. The key characteristics that set stainless wire mesh apart from other materials are its resistance to rust and corrosion, high tensile strength, and ability to withstand extreme temperatures. These properties make it particularly suitable for use in environments where durability and hygiene are paramount.

Applications of Stainless Wire Mesh

The versatility of stainless wire mesh leads to its applications across multiple industries

1. Construction Stainless wire mesh is widely used in construction for reinforcing concrete structures. Its strength contributes to increased durability and longevity in buildings, bridges, and roads.

2. Food Processing In the food industry, stainless wire mesh is utilized in processing equipment and for food safety applications. Its non-reactive nature makes it an ideal choice for environments where hygiene is critical.

3. Pharmaceuticals The pharmaceutical industry relies on stainless wire mesh for filtration applications to ensure that products meet stringent safety and quality standards.

4. Automotive Stainless wire mesh is used in automotive components for filtration systems and as protective shields. Its ability to endure harsh conditions makes it suitable for high-demand applications.

5. Industrial Filtration Various industries, including oil and gas, water treatment, and chemical processing, employ stainless wire mesh for filtration purposes to separate solids from liquids effectively.

The Manufacturing Process

The manufacturing of stainless wire mesh involves several critical steps

stainless wire mesh manufacturers

1. Wire Production The process begins with the production of stainless steel wire, which can vary in thickness and type depending on the specific application. High-quality raw materials are crucial to ensure the final product’s durability and performance.

2. Weaving Once the wire is produced, it is woven into different mesh patterns. The type of weave can vary based on the final use of the mesh, and manufacturers offer various styles, such as plain weave, twill weave, and Dutch weave, to accommodate different filtration requirements.

3. Finishing Post-weaving, the stainless wire mesh is often treated with various finishing processes to enhance its corrosion resistance and improve its mechanical properties. This may include pickling, passivation, or coating processes.

4. Quality Control Rigorous quality control procedures are implemented throughout the manufacturing process to ensure that the stainless wire mesh meets the required specifications. This includes testing for dimensional accuracy, tensile strength, and corrosion resistance.

Factors Contributing to Market Growth

Several factors are fueling the growth of the stainless wire mesh manufacturing market

1. Increasing Industrialization As countries across the globe continue to industrialize, there is a heightened demand for durable materials, including stainless wire mesh, particularly in sectors like construction and manufacturing.

2. Technological Advancements Innovations in manufacturing processes and the development of new types of stainless steel have expanded the range of applications for stainless wire mesh. Manufacturers are leveraging technology to improve product quality and performance.

3. Environmental Regulations Stricter environmental regulations are driving the demand for non-corrosive and long-lasting materials like stainless wire mesh, which can be recycled and reused, contributing to sustainability efforts.

4. Customized Solutions The ability of manufacturers to provide tailored solutions to meet specific client requirements is also boosting demand. Customizable mesh sizes, openings, and material grades allow end-users to find the perfect fit for their applications.

Conclusion

As industries continue to evolve and prioritize sustainability, hygiene, and durability, the importance of stainless wire mesh manufacturers becomes increasingly evident. By understanding the applications, manufacturing processes, and market trends, stakeholders can make informed decisions that leverage the advantages of stainless wire mesh to meet their specific needs. With ongoing advancements in manufacturing technology and heightened awareness of material properties, the future of the stainless wire mesh industry looks promising.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025