-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Авг . 12, 2025 01:20 Back to list

3D Curved Welded Mesh Fence: Enhanced Security & Durability

The Evolution of Perimeter Security: Introducing 3D Curved Welded Wire Mesh Fence

In the rapidly evolving landscape of infrastructure and property development, the demand for robust, aesthetically pleasing, and cost-effective perimeter security solutions has never been higher. Traditional fencing materials often fall short in balancing these crucial aspects. The 3D Curved Welded Wire Mesh Fence emerges as a leading innovation, redefining the standards for modern fencing. This advanced system, characterized by its unique curved design, offers enhanced rigidity, superior anti-climb features, and a distinctive visual appeal that seamlessly integrates into diverse environments. Unlike flat panel fences, the three-dimensional bends not only add structural strength but also create an optical deterrent, making it a preferred choice for applications ranging from industrial parks and public facilities to residential complexes and sports venues. Its strategic design significantly reduces susceptibility to bending and impact, ensuring a longer service life and lower maintenance costs over time.

The rising global focus on asset protection, coupled with urbanization and the expansion of critical infrastructure, is driving significant market growth in high-security fencing. Industry reports project the global perimeter security market to reach approximately USD 35 billion by 2027, with a compound annual growth rate (CAGR) of 9.5% from 2022 to 2027. This growth is largely fueled by increasing security concerns, technological advancements in detection systems, and the adoption of advanced materials like the 3D Curved Welded Wire Mesh Fence. Clients in both the public and private sectors are increasingly seeking solutions that offer a blend of high security, durability, and minimal visual obstruction. The inherent strength-to-weight ratio and versatile application profiles position this specific fencing solution as a cornerstone in future security strategies, catering to a broad spectrum of security needs while maintaining an unobtrusive presence.

Technical Parameters & Key Specifications

Understanding the technical specifications of a 3D Curved Welded Wire Mesh Fence is crucial for B2B decision-makers. These fences are typically manufactured from high-quality low carbon steel wire or galvanized steel wire, ensuring robust performance and longevity. The standard wire diameters range from 4.0mm to 6.0mm, with tighter gauges providing superior strength and security. Mesh sizes, often referred to as aperture, commonly range from 50x100mm to 50x200mm, influencing both visibility and anti-climb efficacy. The distinctive '3D' aspect is achieved through multiple horizontal V-shaped bends, typically 2 to 4 bends per panel, adding significant rigidity and preventing warping. Surface treatments are paramount for corrosion resistance and include hot-dipped galvanizing, electro-galvanizing, and PVC powder coating or spraying. Hot-dipped galvanizing offers a zinc coating thickness of 60-80g/m² (or more for specific applications), providing excellent long-term protection against rust, especially in harsh environments.

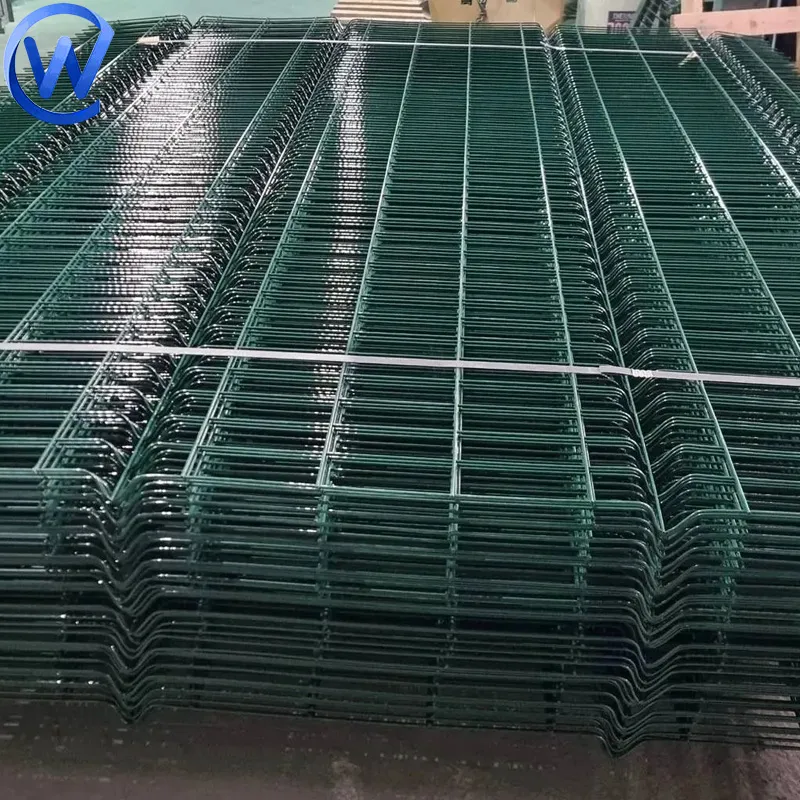

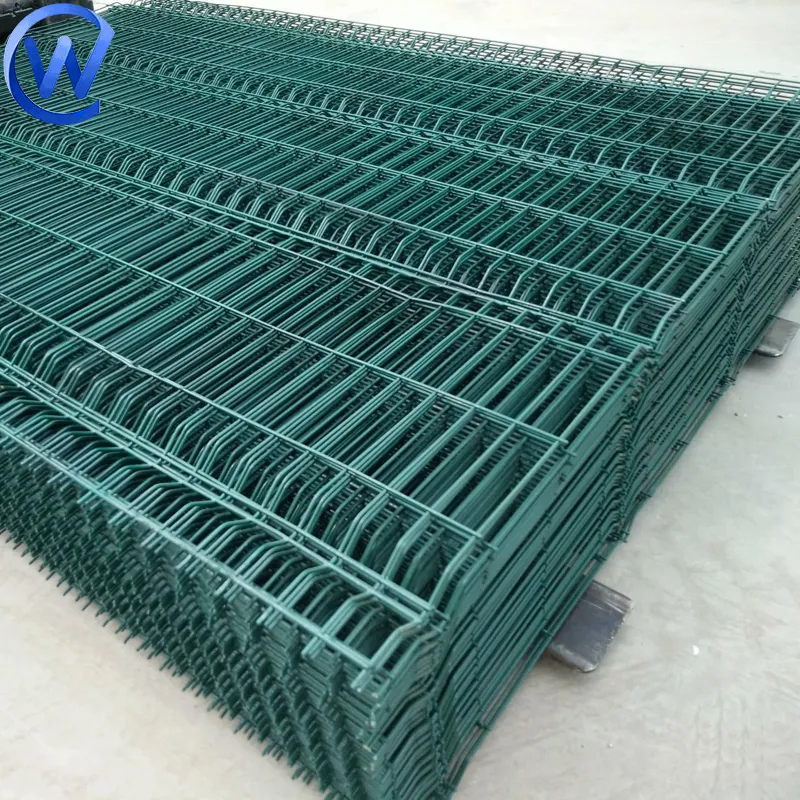

Image 1: A close-up view of a 3D Curved Welded Wire Mesh Fence panel showcasing its distinctive V-bends.

To provide a clear comparative overview, here is a typical specification table for a 3D Curved Welded Wire Mesh Fence:

| Parameter | Typical Range / Value |

|---|---|

| Material | High-quality Low Carbon Steel Wire, Galvanized Wire |

| Wire Diameter (Gauge) | 4.0mm - 6.0mm (e.g., 8-gauge to 6-gauge) |

| Mesh Opening (Aperture) | 50x100mm, 50x150mm, 50x200mm, 75x150mm |

| Panel Height | 1.2m - 2.5m (4 ft - 8 ft) |

| Panel Width | 2.0m - 3.0m (6.5 ft - 10 ft) |

| Number of 3D Curves | 2-4 per panel (depending on height) |

| Surface Treatment | Hot-dipped Galvanized, Electro-Galvanized + PVC Powder Coated/Sprayed |

| Zinc Coating Thickness (Hot-dip) | Typically 60-80 g/m², up to 275 g/m² for enhanced corrosion protection |

| PVC Coating Thickness | 0.1mm - 0.5mm |

| Post Type | Square Post, Round Post, Peach Post, I-Post |

| Standard Compliance | ISO 9001:2015, ASTM F2453, EN 10223-4 |

These parameters directly impact the fence's performance, durability, and suitability for specific environments. For instance, a heavier gauge wire combined with a smaller mesh aperture and robust hot-dipped galvanizing plus powder coating offers maximum security and longevity, crucial for high-security applications in coastal or industrial zones. The selection of the appropriate post type and fixing mechanism (e.g., clips, clamps) also plays a vital role in the overall structural integrity of the 3D Curved Welded Wire Mesh Fence system.

Manufacturing Process: Precision and Quality Assurance

The production of a high-quality 3D Curved Welded Wire Mesh Fence is a meticulous multi-stage process that emphasizes precision engineering and rigorous quality control. It begins with the selection of premium raw materials, typically high-grade low carbon steel wire, which undergoes extensive testing for tensile strength and ductility to ensure it meets international standards such as ASTM A641/A641M. This initial material quality is foundational to the final product's integrity and long-term performance.

Image 2: Automated welding machinery at work, forming the mesh panels.

The core manufacturing steps involve:

- Wire Drawing: Raw steel rods are drawn through dies to achieve the desired wire diameter, enhancing their strength and surface finish.

- Welding: Wires are precision-welded using automated machinery to form the mesh panels. Resistance welding ensures strong, consistent joints at every intersection, crucial for the panel's structural stability. Adherence to standards like EN 10223-4 for welded steel wire fencing is critical here.

- Curving/Bending: The welded mesh panels are then fed into specialized bending machines that create the distinctive V-shaped curves. This process adds significant rigidity and anti-climb properties to the fence panel.

- Surface Treatment: This is a critical stage for corrosion resistance. Options include hot-dipped galvanizing, where the panel is immersed in molten zinc for a thick, protective coating, or electro-galvanizing followed by PVC powder coating. PVC coating provides an additional layer of protection against UV degradation and enhances aesthetic appeal, with a wide range of RAL colors available. The coating process adheres to standards like ISO 1461 for galvanizing and ASTM D3451 for powder coatings.

- Quality Inspection: Each panel undergoes rigorous inspection for weld integrity, dimensional accuracy (panel size, mesh opening, curve consistency), coating thickness, and visual defects. This multi-point inspection ensures compliance with international quality management systems like ISO 9001:2015, guaranteeing a product that performs as expected in diverse operational environments.

This structured approach, from raw material sourcing to final inspection, ensures that every 3D Curved Welded Wire Mesh Fence panel delivered offers unparalleled strength, durability, and a service life typically exceeding 15-20 years, even in challenging climatic conditions. The anti-corrosion properties, particularly from advanced galvanization and powder coating, significantly reduce lifecycle costs by minimizing the need for frequent maintenance or replacement.

Technical Advantages & Performance Benefits

The 3D Curved Welded Wire Mesh Fence offers a compelling suite of technical advantages that make it superior to conventional fencing solutions. Its inherent rigidity, derived from the engineered V-bends, provides exceptional resistance to impact and deformation, making it highly difficult to cut or climb without specialized tools. This structural integrity translates directly into enhanced security for restricted areas. The high tensile strength of the individual wires, combined with robust welding, ensures a formidable barrier that can withstand significant external forces, including attempts at forced entry or harsh weather conditions.

Image 3: Illustrating the high durability and aesthetic integration of the fence in a public space.

- Superior Corrosion Resistance: The multi-layer anti-corrosion treatment, comprising hot-dipped galvanization and/or high-quality PVC powder coating, provides an unparalleled defense against rust, saline environments, and chemical exposure. This extends the fence's lifespan significantly, even in coastal regions or industrial zones where traditional materials would quickly degrade.

- Enhanced Security Features: The narrow mesh openings combined with the curved profile make it extremely difficult for intruders to gain a foothold or handhold, effectively deterring climbing. This is a critical anti-climb feature sought by high-security facilities.

- Aesthetic Appeal: Beyond its security function, the modern and sleek design of the 3D Curved Welded Wire Mesh Fence offers significant aesthetic advantages. Its clean lines and customizable colors allow it to blend seamlessly into various architectural styles and landscapes, from contemporary urban developments to green spaces.

- Cost-Effectiveness & Low Maintenance: The exceptional durability and resistance to environmental factors mean fewer repairs and replacements over time, leading to substantial long-term cost savings. Its robust construction requires minimal upkeep, reducing operational expenditures for property managers and owners.

- Ease of Installation: Despite its strength, the modular design of the panels and posts allows for relatively quick and straightforward installation, reducing labor costs and project timelines. This efficiency is particularly beneficial for large-scale infrastructure projects.

These combined attributes make the 3D Curved Welded Wire Mesh Fence a smart, sustainable investment for entities prioritizing long-term security, visual integration, and operational efficiency. Its performance metrics consistently outperform many alternative fencing types, offering a tangible return on investment through reduced maintenance and enhanced asset protection.

Application Scenarios & Illustrative Case Studies

The versatility of the 3D Curved Welded Wire Mesh Fence makes it an ideal solution for a diverse range of applications requiring a blend of security, visibility, and aesthetics. Its robust design is particularly well-suited for environments where both deterrent capabilities and an unobtrusive appearance are crucial. Common application areas include:

Image 4: 3D Curved Welded Wire Mesh Fence securing critical infrastructure, demonstrating both functionality and integration.

- Commercial and Industrial Parks: Providing secure perimeters for factories, warehouses, and office complexes, deterring unauthorized access while maintaining a professional appearance.

- Public Facilities: Fencing for schools, hospitals, parks, and recreational areas, ensuring public safety without creating an overly restrictive feel.

- Transportation Infrastructure: Securing airports, railways, highways, and ports against trespassers and vandalism. Its transparency aids surveillance.

- Residential Complexes: Offering reliable security for gated communities, apartments, and private residences, enhancing property value and peace of mind.

- Sports Facilities: Enclosing sports fields, tennis courts, and stadiums, serving as both a boundary and a protective barrier.

- Government and Military Sites: Providing a foundational layer of security for sensitive installations.

Case Study: Securing the "Greenridge Industrial Hub"

A prominent industrial hub, "Greenridge Industrial Hub," spanning over 50 hectares, faced persistent issues with perimeter security, including unauthorized vehicle and pedestrian access, and minor incidents of theft. Traditional chain-link fencing proved inadequate in deterring determined intruders. The management required a solution that offered enhanced security, was low maintenance, and provided a modern, uniform appearance across the expansive site.

After a thorough evaluation, they selected a 3D Curved Welded Wire Mesh Fence system. Over 10 kilometers of 2.2-meter high panels with 50x200mm mesh aperture and 5.0mm wire diameter, hot-dipped galvanized and then PVC powder coated in RAL 6005 (Moss Green), were installed. The installation included heavy-duty square posts with anti-tamper fixings. The curved design significantly increased rigidity and deterred climbing attempts. Post-installation, the hub reported a 70% reduction in unauthorized entries within the first six months, attributed directly to the robust physical barrier and the visual deterrence provided by the new fencing. The low-maintenance requirements also led to an estimated 30% reduction in annual perimeter upkeep costs. This project exemplifies how the 3D Curved Welded Wire Mesh Fence can deliver both superior security and long-term operational efficiencies in large-scale industrial applications.

Choosing Your Partner: Manufacturer Comparison & Customization

Selecting the right manufacturer for your 3D Curved Welded Wire Mesh Fence project is as crucial as the product itself. The market offers a range of suppliers, but discerning factors such as manufacturing expertise, quality control protocols, and customization capabilities are paramount. Reputable manufacturers distinguish themselves through adherence to international standards like ISO 9001 for quality management, ensuring consistency and reliability across their product lines. Look for manufacturers with comprehensive testing facilities and certifications, demonstrating a commitment to the durability and performance of their fencing solutions. For instance, a manufacturer that provides clear material certifications (e.g., steel grade, zinc coating thickness) and performance test reports (e.g., salt spray tests for corrosion resistance) offers greater assurance of product longevity.

Image 5: Demonstrating a customized 3D Curved Welded Wire Mesh Fence integrated with access control for a specific client need.

Customization is a significant advantage offered by leading manufacturers. While standard panel sizes and specifications are available, complex projects often require tailored solutions. This includes varying panel heights and widths, specific wire gauges and mesh apertures for unique security requirements, and a broad palette of RAL colors for aesthetic integration. Beyond the panels, customization extends to post types (e.g., square, round, peach, or I-beam), specific gate designs (swing, sliding, cantilever), and integration with other security features such as barbed wire, razor wire, or electronic detection systems. A manufacturer capable of offering a full suite of accessories and integrated solutions, coupled with robust technical support and project consultation, becomes an invaluable partner. Their ability to provide detailed CAD drawings, structural analysis, and installation guidelines tailored to specific site conditions further streamlines project execution and ensures optimal performance of the 3D Curved Welded Wire Mesh Fence system.

Ensuring Trust: Quality Assurance, Warranty & Support

Building trust with B2B clients requires more than just a high-quality product; it demands transparent processes, clear commitments, and reliable support. For 3D Curved Welded Wire Mesh Fence solutions, this begins with stringent quality assurance protocols certified by international bodies. A reputable supplier will proudly display certifications such as ISO 9001:2015 for Quality Management Systems, demonstrating a consistent commitment to manufacturing excellence. Furthermore, compliance with specific product standards like ASTM (American Society for Testing and Materials) or EN (European Norms) for welded mesh and coatings ensures the product meets or exceeds industry benchmarks for performance and durability. Many top-tier manufacturers also adhere to ISO 14001 for environmental management and ISO 45001 for occupational health and safety, showcasing a holistic approach to responsible business practices.

Image 6: Demonstrating the robust packaging and quality control before shipment of 3D Curved Welded Wire Mesh Fence.

Key components of a trustworthy partnership include:

- Product Warranty: Leading manufacturers typically offer substantial warranties, ranging from 10 to 20 years, on their 3D Curved Welded Wire Mesh Fence products, particularly on the anti-corrosion coating. This warranty period reflects confidence in the product's longevity and performance under normal usage and environmental conditions, offering peace of mind to the client.

- Delivery Cycle: Efficient logistics and transparent delivery schedules are critical for project planning. A reliable supplier provides clear lead times, manages production capacities effectively, and has robust global shipping capabilities to ensure on-time delivery, minimizing project delays. For standard orders, typical delivery can range from 2-4 weeks, while large custom orders may require 6-8 weeks, depending on complexity.

- Customer Support: Post-sales support, including technical assistance, installation guidance, and problem resolution, is vital. A dedicated customer service team, available for consultations and addressing any concerns, ensures a smooth experience from order placement through installation and beyond.

- After-Sales Service: This encompasses availability of spare parts, guidance on maintenance, and support for any unforeseen issues. A strong after-sales commitment reinforces the manufacturer's long-term partnership approach.

Frequently Asked Questions (FAQ)

- Q: What is the expected lifespan of a 3D Curved Welded Wire Mesh Fence?

A: With proper galvanization and PVC coating, these fences typically have a service life of 15 to 20 years, even in challenging weather conditions. - Q: Can the fence be customized for specific heights or colors?

A: Yes, leading manufacturers offer extensive customization options, including various panel heights, widths, wire gauges, mesh apertures, and a wide range of RAL colors to match project aesthetics. - Q: Is the installation process complex for large projects?

A: The modular design facilitates relatively straightforward installation. Reputable suppliers provide comprehensive installation guides and technical support, and some may even offer on-site supervision or training. - Q: How does the 3D curve enhance security?

A: The V-shaped curves significantly increase the panel's rigidity, making it resistant to bending and cutting. They also make it extremely difficult for intruders to gain a foothold or handhold, enhancing anti-climb capabilities.

Conclusion: The Future of Secure Boundaries

The 3D Curved Welded Wire Mesh Fence represents a significant advancement in perimeter security, offering a sophisticated blend of robust protection, enduring durability, and contemporary aesthetics. Its engineered design, meticulous manufacturing process, and advanced anti-corrosion treatments ensure a long service life with minimal maintenance, translating into substantial long-term cost savings for businesses and organizations. As security challenges evolve and architectural designs become more integrated with functional elements, this fencing solution stands out as a versatile and reliable choice for a vast array of applications, from industrial complexes and critical infrastructure to public parks and residential developments. By selecting a manufacturer committed to stringent quality standards, comprehensive customization, and exceptional post-sales support, B2B clients can confidently invest in a fencing system that not only meets immediate security needs but also offers a sustainable, value-driven solution for years to come. The continued innovation in materials science and coating technologies further promises to enhance the performance envelope of these indispensable security barriers.

References

- International Journal of Security Engineering and Applications, "Advanced Materials in Perimeter Security: A Comparative Study of Welded Mesh Systems."

- Journal of Civil Engineering and Construction Management, "Structural Integrity and Durability of 3D Welded Mesh Fencing in Harsh Environments."

- Environmental Protection and Corrosion Science, "Long-Term Performance of Galvanized and Polymer-Coated Steel in Outdoor Applications."

- Global Market Insights, "Perimeter Security Market Size, Share & Trends Analysis Report."

- Standards Australia/New Zealand (AS/NZS) Handbook for Wire Mesh Fences - Guidelines for Design and Installation.

This is the last article

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025