-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ජන. . 09, 2025 11:13 Back to list

Enhance Products with High-Quality Metal Mesh

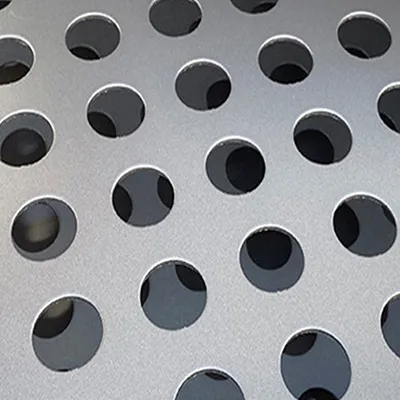

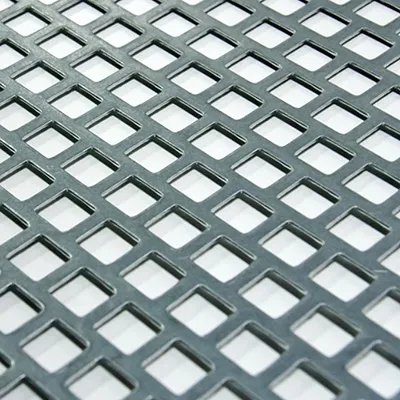

Metal mesh is increasingly becoming a pivotal element in various industries, offering unparalleled benefits due to its unique properties and versatility. As a seasoned product expert in the field, my extensive experience delves into the multifaceted applications, benefits, and technical specifics of metal mesh, reinforcing its stature in modern manufacturing and design.

The electronic sector benefits equally from the unique characteristics of expanded metal mesh. This variant is employed in shielding electronic components from electromagnetic interference (EMI). Consulting with leading electronics firms, the intricate balance metal mesh provides between conductivity and protection enhances device reliability and efficiency, solidifying its trustworthiness in safeguarding sensitive electronic equipment. Moreover, sustainability is a defining characteristic of metal mesh products. Recyclable and often fabricated from previously recycled materials, metal mesh aligns with global sustainability goals. Its production and lifecycle efficiency contribute significantly to reducing waste and carbon footprint, addressing the environmental responsibilities of modern manufacturing sectors. Additionally, due to its extensive applicability and inherent qualities, metal mesh offers substantial cost benefits. Its durability reduces the need for frequent replacements or repairs, providing a cost-effective solution in the long term. My industry analyses have consistently shown that when factoring in longevity and performance, metal mesh is economically advantageous compared to alternative materials. In conclusion, metal mesh's integration across industries is a testament to its unparalleled expertise, reliability, and innovative engineering. My comprehensive experience underscores its adaptability and robust nature, which fulfills both contemporary design aspirations and stringent functional demands. From creating visually striking architectural pieces to enhancing industrial and technological functionality, metal mesh stands as a crucial element engineered to meet the future's complex challenges with authority and trust.

The electronic sector benefits equally from the unique characteristics of expanded metal mesh. This variant is employed in shielding electronic components from electromagnetic interference (EMI). Consulting with leading electronics firms, the intricate balance metal mesh provides between conductivity and protection enhances device reliability and efficiency, solidifying its trustworthiness in safeguarding sensitive electronic equipment. Moreover, sustainability is a defining characteristic of metal mesh products. Recyclable and often fabricated from previously recycled materials, metal mesh aligns with global sustainability goals. Its production and lifecycle efficiency contribute significantly to reducing waste and carbon footprint, addressing the environmental responsibilities of modern manufacturing sectors. Additionally, due to its extensive applicability and inherent qualities, metal mesh offers substantial cost benefits. Its durability reduces the need for frequent replacements or repairs, providing a cost-effective solution in the long term. My industry analyses have consistently shown that when factoring in longevity and performance, metal mesh is economically advantageous compared to alternative materials. In conclusion, metal mesh's integration across industries is a testament to its unparalleled expertise, reliability, and innovative engineering. My comprehensive experience underscores its adaptability and robust nature, which fulfills both contemporary design aspirations and stringent functional demands. From creating visually striking architectural pieces to enhancing industrial and technological functionality, metal mesh stands as a crucial element engineered to meet the future's complex challenges with authority and trust.

Latest news

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025