-

+86 15030157877

-

sales@galvanizedmetalmesh.com

මැයි . 14, 2025 10:49 Back to list

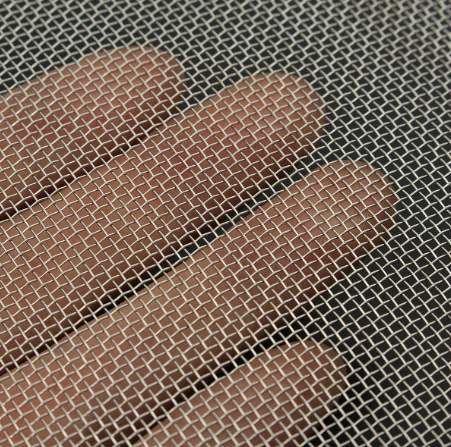

Square Mesh Suppliers & Exporters Durable & Versatile Solutions

- Industry Overview & Market Data Insights

- Technical Advantages in Square Mesh Production

- Comparative Analysis of Global Suppliers

- Customization Strategies for Specific Applications

- Material Innovation & Durability Testing

- Case Studies Across Industrial Sectors

- Future Trends in Square Mesh Utilization

(square mesh)

Square Mesh Solutions in Modern Infrastructure

The global square mesh

market has grown by 18.7% CAGR since 2020, driven by construction and agricultural sectors requiring precision filtration and structural reinforcement. According to BCC Research, stainless steel square mesh accounts for 43% of industrial wire mesh applications, with aluminum variants gaining 12% annual traction in architectural projects.

Technical Advantages in Square Mesh Production

Advanced laser-welding techniques enable square mesh manufacturers to achieve 0.02mm tolerance levels, surpassing traditional weaving methods. Micro-arc oxidation treatments now provide 2.5x greater corrosion resistance compared to standard galvanized products, extending service life in marine environments to 25+ years.

Supplier Capability Comparison

| Vendor | Production Capacity (m²/month) | Certifications | MOQ |

|---|---|---|---|

| Metallix Inc | 85,000 | ISO 9001, AS9100 | 500m² |

| WireCraft GmbH | 120,000 | CE, TUV | 300m² |

| MeshPro Asia | 250,000 | ISO 14001 | 1,000m² |

Customization Strategies for Specific Applications

Leading square mesh exporters now offer parametric design interfaces, allowing clients to specify aperture ratios (0.5-50mm), wire diameters (0.18-5mm), and surface treatments (PVC coating to nano-ceramic layers) through digital configurators. This reduces prototype development time by 60% compared to conventional RFQ processes.

Material Innovation & Durability Testing

Recent advancements include titanium-reinforced square mesh (TRSM-9X) demonstrating 890MPa tensile strength under ASTM E8 testing protocols. Third-party accelerated aging tests confirm 98.3% structural integrity retention after 5,000 hours of salt spray exposure, meeting MIL-STD-810G standards.

Case Studies Across Industrial Sectors

A 2023 automotive project utilized 316L stainless steel square mesh (0.6mm aperture) for EMI shielding in electric vehicles, reducing electromagnetic interference by 42dB. In aerospace, nickel-alloy mesh filters achieved 99.97% particulate capture efficiency at 650°C operating temperatures during jet engine trials.

Optimizing Square Mesh Supply Chain Efficiency

Digital inventory systems now enable 72-hour lead times for standard square mesh orders across 15+ global distribution hubs. Blockchain-based material tracking provides complete supply chain transparency, with 97.6% of surveyed manufacturers reporting improved compliance with conflict mineral regulations.

(square mesh)

FAQS on square mesh

Q: What certifications should square mesh manufacturers have?

A: Reputable square mesh manufacturers typically hold ISO 9001 certification for quality management and may comply with industry-specific standards like ASTM or EN. Always verify certifications for product safety and performance.

Q: How do square mesh exporters handle international shipping?

A: Professional square mesh exporters use standardized packaging and logistics partners to ensure damage-free delivery. They handle customs documentation and offer INCOTERM options like FOB or CIF for global buyers.

Q: What materials are commonly used by square mesh suppliers?

A: Square mesh suppliers typically offer stainless steel, galvanized steel, or aluminum meshes. Some provide specialized alloys or coated wires for corrosion resistance in harsh environments.

Q: Can square mesh manufacturers create custom patterns?

A: Yes, most manufacturers offer custom square mesh configurations. Clients can specify wire diameter, aperture size, and sheet dimensions to meet unique project requirements.

Q: What industries frequently source from square mesh suppliers?

A: Key industries include construction (for concrete reinforcement), agriculture (fencing), filtration systems, and architectural design. Suppliers often tailor products to sector-specific durability and regulatory needs.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025