-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஜன . 09, 2025 11:49 Back to list

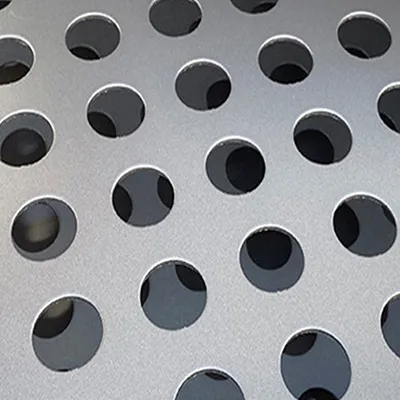

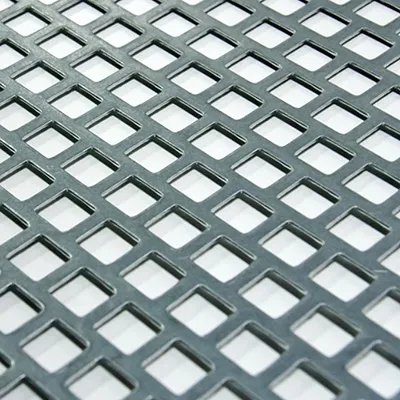

Perforated Metal Mesh

Metal mesh has been transforming industries and applications with its unique properties that cater to a wide range of needs. Its intricate weaving of metal wires creates a fabric-like material that offers both aesthetic appeal and functional benefits. Over the years, metal mesh has garnered appreciation from sectors such as architecture, automotive, filtration, and beyond, thanks to its versatility and robustness.

In terms of authoritativeness, metal mesh has established itself as a key player across numerous engineering solutions. It plays a crucial role in filtration systems due to its ability to handle high pressure and temperature conditions. Industries ranging from petrochemical to food processing rely on metal mesh filters for sieving particles and ensuring product purity. Moreover, its adaptability in acoustic applications, where it serves in soundproofing and noise regulation, underscores its broad scope of utility. Trustworthiness of metal mesh as a product is reflected in its longstanding use and continuous innovation. Manufacturers are consistently advancing production techniques to enhance the mesh’s properties, aiming for improved performance in specific conditions. This has included advancements like nano-coatings for increased resistivity to environmental factors, or hybrid meshes that combine various materials for optimized characteristics. Moreover, the sustainability aspect of metal mesh adds to its credibility. With growing awareness towards eco-friendly construction and manufacturing practices, metal mesh stands out due to its recyclability and durability, promoting longer life cycles and reduced waste. In conclusion, metal mesh is not just a materials choice; it's a strategic investment in quality and functionality. Its broad appeal in innovative design and its application prowess in demanding industrial environments highlight its invaluable contribution to modern advancements. As industries continue to evolve, the reliance on materials like metal mesh that offer reliability and efficiency will undoubtedly increase, marking it as a staple in both development and design for years to come.

In terms of authoritativeness, metal mesh has established itself as a key player across numerous engineering solutions. It plays a crucial role in filtration systems due to its ability to handle high pressure and temperature conditions. Industries ranging from petrochemical to food processing rely on metal mesh filters for sieving particles and ensuring product purity. Moreover, its adaptability in acoustic applications, where it serves in soundproofing and noise regulation, underscores its broad scope of utility. Trustworthiness of metal mesh as a product is reflected in its longstanding use and continuous innovation. Manufacturers are consistently advancing production techniques to enhance the mesh’s properties, aiming for improved performance in specific conditions. This has included advancements like nano-coatings for increased resistivity to environmental factors, or hybrid meshes that combine various materials for optimized characteristics. Moreover, the sustainability aspect of metal mesh adds to its credibility. With growing awareness towards eco-friendly construction and manufacturing practices, metal mesh stands out due to its recyclability and durability, promoting longer life cycles and reduced waste. In conclusion, metal mesh is not just a materials choice; it's a strategic investment in quality and functionality. Its broad appeal in innovative design and its application prowess in demanding industrial environments highlight its invaluable contribution to modern advancements. As industries continue to evolve, the reliance on materials like metal mesh that offer reliability and efficiency will undoubtedly increase, marking it as a staple in both development and design for years to come.

Next:

Latest news

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025