-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஜன . 09, 2025 14:02 Back to list

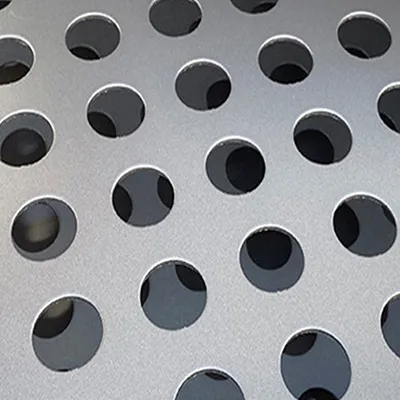

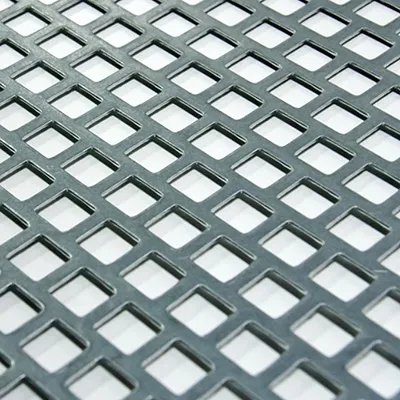

metal mesh

Metal mesh stands as a testament to the evolution of materials used in diverse applications, ranging from architectural marvels to industrial utilities. Drawing from years of experience in material sciences, one can appreciate the versatility and adaptability of metal mesh in both aesthetic and functional domains.

The manufacturing of metal mesh adheres to rigorous standards, bolstering its credibility in safety-critical sectors such as aerospace and automotive. Here, precision engineering ensures consistency and quality, positioning metal mesh as a trustworthy material in the most demanding technical environments. Specialists in these fields recognize the importance of quality control and material verification, crucial elements in maintaining the integrity of metal mesh products. For those looking to incorporate metal mesh into their projects or products, understanding its capabilities and limitations is essential. Engaging with reputable suppliers who provide detailed technical specifications and compliance certifications adds a layer of trust to the procurement process. Seasoned professionals often recommend consulting with material scientists or engineers during the design phase to maximize the benefits of metal mesh while mitigating potential drawbacks. In conclusion, metal mesh stands as a pillar of innovation across various sectors due to its unique properties and adaptability. Its uses are as diverse as the materials it is made from, each with specific applications that showcase the expertise and engineering prowess behind its continued evolution. For anyone seeking a material that offers both beauty and function, metal mesh remains an authoritative and trustworthy choice in the modern landscape.

The manufacturing of metal mesh adheres to rigorous standards, bolstering its credibility in safety-critical sectors such as aerospace and automotive. Here, precision engineering ensures consistency and quality, positioning metal mesh as a trustworthy material in the most demanding technical environments. Specialists in these fields recognize the importance of quality control and material verification, crucial elements in maintaining the integrity of metal mesh products. For those looking to incorporate metal mesh into their projects or products, understanding its capabilities and limitations is essential. Engaging with reputable suppliers who provide detailed technical specifications and compliance certifications adds a layer of trust to the procurement process. Seasoned professionals often recommend consulting with material scientists or engineers during the design phase to maximize the benefits of metal mesh while mitigating potential drawbacks. In conclusion, metal mesh stands as a pillar of innovation across various sectors due to its unique properties and adaptability. Its uses are as diverse as the materials it is made from, each with specific applications that showcase the expertise and engineering prowess behind its continued evolution. For anyone seeking a material that offers both beauty and function, metal mesh remains an authoritative and trustworthy choice in the modern landscape.

Next:

Latest news

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025