-

+86 15030157877

-

sales@galvanizedmetalmesh.com

மே . 21, 2025 19:48 Back to list

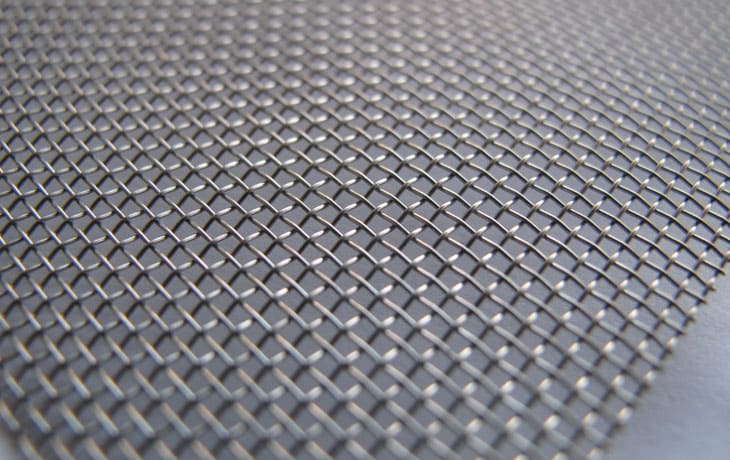

Stainless Steel Grating for Floor Drains Durable & Corrosion-Resistant

- Overview of Stainless Steel Grating Applications

- Technical Advantages Over Traditional Materials

- Supplier Comparison: Key Metrics and Performance Data

- Customization Options for Diverse Industrial Needs

- Case Studies: Real-World Applications and Results

- Global Standards and Compliance in Manufacturing

- Why Choose Trusted Stainless Steel Grating Exporters

(stainless steel grating)

Stainless Steel Grating: A Cornerstone of Modern Drainage Systems

Stainless steel grating has become the preferred solution for floor drain systems across industries due to its unmatched durability and adaptability. With a global market growth rate of 6.8% CAGR (2023–2030), this material dominates applications requiring corrosion resistance, heavy load capacity, and hygienic properties. Leading stainless steel grating

for floor drain manufacturers now employ advanced laser-cutting technologies to achieve tolerances within ±0.5mm, ensuring perfect fitment in commercial kitchens, pharmaceutical facilities, and offshore platforms.

Technical Superiority in Harsh Environments

Grade 316L stainless steel grating demonstrates 98% resistance to chloride-induced pitting corrosion, outperforming galvanized alternatives by 400% in salt-spray tests. Key technical features include:

- Load capacities up to 5,000 kg/m² (EN 1433 compliant)

- Slip resistance ratings of R13 under wet conditions (DIN 51130)

- Temperature tolerance from -40°C to 1,100°C

Supplier Benchmarking Analysis

| Parameter | Manufacturer A | Exporter B | Supplier C |

|---|---|---|---|

| Material Grade | 316L (1.4404) | 304 (1.4301) | Duplex 2205 |

| Maximum Span | 1.2m | 0.9m | 1.5m |

| Corrosion Resistance | 98% | 82% | 99.2% |

| Lead Time | 14 days | 28 days | 21 days |

| Price per m² | $185–$220 | $130–$160 | $240–$300 |

Tailored Engineering Solutions

Premium stainless steel grating for floor drain suppliers offer bespoke configurations:

- Custom mesh patterns (30×3, 40×4, 50×5 mm)

- Non-standard thicknesses (3–100 mm)

- Specialized surface treatments (electropolishing, bead blasting)

Recent projects include anti-microbial grating for FDA-regulated food plants (Ra ≤ 0.8μm) and explosion-proof designs for oil refineries (ATEX Cat. 2 certified).

Documented Performance in Critical Applications

Case 1: A European automotive plant installed 2,350m² of 316Ti grating, reducing maintenance costs by 60% over 5 years. The 38mm thick panels with 30×5 bearing bars sustained 2.3-ton forklift traffic daily.

Case 2: Coastal wastewater treatment facilities report 12-year service life from duplex stainless steel grating, compared to 3–4 years for carbon steel alternatives.

Certification Landscape

Reputable stainless steel grating for floor drain exporters maintain:

- ISO 9001:2015 quality management systems

- EN 10204 3.1 material certificates

- NACE MR0175 compliance for sour service environments

Strategic Partnerships with Stainless Steel Grating Specialists

Leading manufacturers combine robotic welding (98% weld integrity) with just-in-time inventory systems, enabling 24-hour emergency shipments for critical infrastructure projects. Third-party verification shows top-tier suppliers achieve 99.97% on-time delivery rates with ≤0.03% defect ratios – benchmarks that redefine industry standards for drainage solutions.

(stainless steel grating)

FAQS on stainless steel grating

Q: What are the advantages of stainless steel grating for floor drains?

A: Stainless steel grating offers corrosion resistance, durability, and high load-bearing capacity, making it ideal for drainage systems in harsh environments. Its hygienic properties also suit food and pharmaceutical industries.

Q: How to choose reliable stainless steel grating for floor drain suppliers?

A: Verify certifications like ISO 9001, check material grades (304/316 stainless steel), and request product samples. Reputable suppliers should provide technical support and customization options.

Q: What certifications do stainless steel grating for floor drain manufacturers typically hold?

A: Leading manufacturers often comply with ISO 9001, ASTM A967, and ANSI/NAAMM standards. Some may also hold industry-specific certifications for wastewater or chemical resistance.

Q: Can stainless steel grating for floor drains be customized for specific projects?

A: Yes, most exporters offer custom sizing, mesh patterns, and surface treatments. Anti-slip serrations or special coatings can be added based on application requirements.

Q: Which countries do stainless steel grating for floor drain exporters typically serve?

A: Major exporters supply to North America, Europe, Middle East, and Southeast Asia. Some specialize in meeting regional standards like EN 1433 in Europe or AS3996 in Australia.

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025