-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஏப் . 15, 2024 11:19 Back to list

Fiberglass Grating Sheets vs. Steel Grating: Making the Right Choice Steel Grating

Introduction

When it comes to choosing the right grating material for your industrial or commercial project, there are several factors to consider. Fiberglass grating sheets and steel grating are two popular options, each with its own set of advantages and disadvantages. In this article, Unicomposite composite profiles will dive deep into the comparison between these two materials to help you make an informed decision that suits your specific needs.

fiberglass grating sheets

Understanding Fiberglass Grating Sheets

The Composition and Structure

Fiberglass grating sheets are composed of reinforced fiberglass plastic, making them lightweight yet incredibly durable. These sheets are manufactured by weaving together glass fibers with a thermosetting resin, creating a strong and corrosion-resistant material.

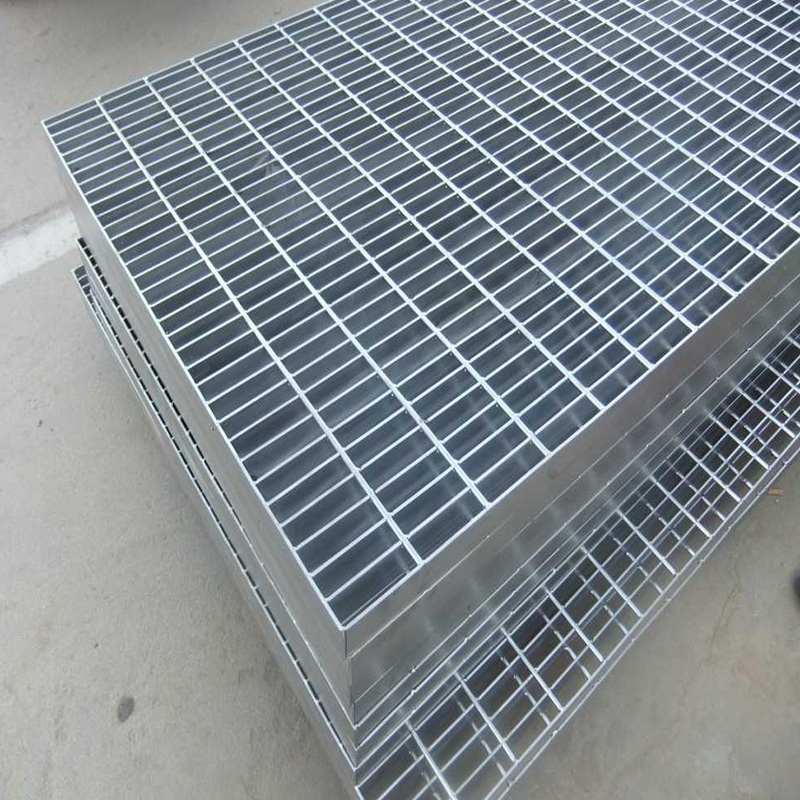

Steel Grating

Benefits of Fiberglass Grating Sheets

- Corrosion Resistance: One of the standout features of fiberglass grating is its exceptional resistance to corrosion. This makes it an ideal choice for outdoor or corrosive environments, as it can withstand exposure to chemicals and moisture without deteriorating.

- Lightweight Nature: Fiberglass grating is significantly lighter than steel grating. This characteristic simplifies the installation process and reduces the load on support structures, potentially leading to cost savings.

- Low Maintenance: Due to its corrosion-resistant properties, fiberglass grating requires minimal maintenance. It doesn’t require painting, and its surface is easy to clean, further reducing long-term costs.

Exploring Steel Grating

The Composition and Structure

Steel grating is crafted from welded or pressure-locked steel panels. It is known for its robustness and strength, making it suitable for heavy-load applications.

Advantages of Steel Grating

- High Load-Bearing Capacity: Steel grating boasts exceptional load-bearing capabilities, making it suitable for areas with heavy foot traffic or equipment. It can withstand substantial weights without compromising its structural integrity.

- Durability: Steel grating is known for its longevity and toughness. It can withstand harsh conditions, making it a reliable choice for industrial settings.

- Fire Resistance: Steel is naturally fire-resistant, which makes steel grating a preferred option in environments where fire safety is a concern.

Comparing the Two: Fiberglass vs. Steel Grating

Weight and Installation

Fiberglass grating’s lightweight nature makes it easier to handle during installation. On the other hand, steel grating’s weight may require additional manpower and equipment for proper installation.

Corrosion Resistance

While both materials offer corrosion resistance, fiberglass grating has the upper hand in this aspect due to its immunity to rust and chemical degradation.

Load-Bearing Capacity

Steel grating surpasses fiberglass in terms of load-bearing capacity, making it suitable for heavy-duty applications in industrial sectors.

Maintenance and Longevity

Fiberglass grating requires less maintenance and is less susceptible to rusting, contributing to a longer lifespan compared to steel grating.

Which One to Choose and Why?

The choice between fiberglass grating sheets and steel grating ultimately depends on your specific project requirements. If you’re looking for corrosion resistance, low maintenance, and ease of installation, fiberglass grating is the way to go. On the other hand, if you require unmatched load-bearing capacity and durability, steel grating should be your choice.

Conclusion

In the fiberglass grating sheets vs. steel grating debate, both materials have their unique strengths. Your decision should be based on a careful evaluation of your project’s needs and priorities. By considering factors like weight, corrosion resistance, load-bearing capacity, and maintenance, you can confidently select the material that aligns with your goals.

FAQs

- Is fiberglass grating suitable for heavy industrial environments? Yes, fiberglass grating’s corrosion resistance and durability make it suitable for various industrial settings.

- Can steel grating be used outdoors without rusting? Steel grating can rust over time when exposed to moisture and environmental elements.

- Which material is more cost-effective in the long run? While initial costs may vary, fiberglass grating’s low maintenance requirements often lead to cost savings over its lifespan.

- Can I paint fiberglass grating if I want a different color? Yes, fiberglass grating can be painted, although it’s not necessary for its functionality.

- Are there any eco-friendly aspects associated with these materials? Fiberglass grating’s lightweight nature contributes to reduced transportation emissions, while steel grating is fully recyclable.

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025