-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ม.ค. . 09, 2025 13:48 Back to list

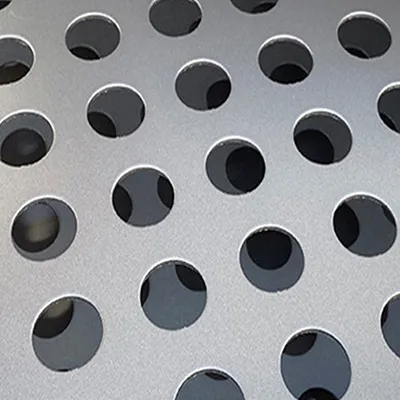

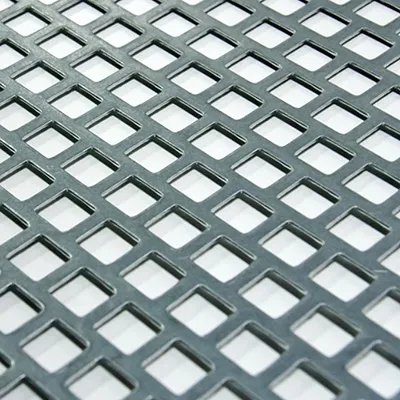

Perforated Metal Mesh

Metal mesh products have emerged as pivotal components in various industries, providing unparalleled functionality and durability. These innovative solutions are crafted from interlocking strands of metal, delivering strength that is both formidable and adaptable. Utilized across sectors, metal mesh products cater to a myriad of applications, making them indispensable.

Notably, metal mesh is indispensable in the aerospace sector. It’s utilized in crafting lightweight, yet robust, components that comply with the rigorous safety standards of the industry. Such applications illustrate the material's credibility and trustworthiness, adhering to the stringent requirements set forth by regulatory bodies. In the consumer market, the versatility of metal mesh extends to everyday products such as household appliances and personal safety gear. Its incorporation in washing machines as drum materials optimizes performance while ensuring durability. Furthermore, metal mesh in protective equipment, like gloves or masks, offers superior safety without compromising usability. Understanding the refining processes behind metal mesh production also enhances its perceived expertise. Techniques such as welding, weaving, and perforating demand precision and highlight the advanced technological capabilities required to produce quality metal mesh products. These processes ensure that each strand of mesh aligns perfectly, which fortifies its structural integrity. Its myriad applications across industries attest to the robust applicability and necessity of metal mesh. As industries continue to evolve, metal mesh will undoubtedly maintain its role as a product that fuses quality with innovation, offering solutions that are both efficient and enduring. The journey of metal mesh illustrates an intersection of traditional methodologies with contemporary demands, highlighting it as a centerpiece of modern manufacturing and design.

Notably, metal mesh is indispensable in the aerospace sector. It’s utilized in crafting lightweight, yet robust, components that comply with the rigorous safety standards of the industry. Such applications illustrate the material's credibility and trustworthiness, adhering to the stringent requirements set forth by regulatory bodies. In the consumer market, the versatility of metal mesh extends to everyday products such as household appliances and personal safety gear. Its incorporation in washing machines as drum materials optimizes performance while ensuring durability. Furthermore, metal mesh in protective equipment, like gloves or masks, offers superior safety without compromising usability. Understanding the refining processes behind metal mesh production also enhances its perceived expertise. Techniques such as welding, weaving, and perforating demand precision and highlight the advanced technological capabilities required to produce quality metal mesh products. These processes ensure that each strand of mesh aligns perfectly, which fortifies its structural integrity. Its myriad applications across industries attest to the robust applicability and necessity of metal mesh. As industries continue to evolve, metal mesh will undoubtedly maintain its role as a product that fuses quality with innovation, offering solutions that are both efficient and enduring. The journey of metal mesh illustrates an intersection of traditional methodologies with contemporary demands, highlighting it as a centerpiece of modern manufacturing and design.

Next:

Latest news

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025