-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ม.ค. . 15, 2025 04:42 Back to list

Steel Grating

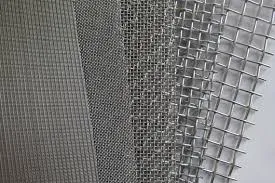

Stainless steel grating is an essential component across various industries, recognized for its strength, durability, and versatility. Through years of experience and expertise in the metal industry, it becomes evident that stainless steel grating offers unparalleled benefits that make it a preferred choice for engineers and architects alike.

Adding to its credentials, stainless steel grating is environmentally friendly. Stainless steel is fully recyclable, contributing to sustainable building practices and eco-friendly manufacturing processes. This trait aligns with the growing global emphasis on reducing environmental footprints, making stainless steel grating an ideal choice for green construction projects. The longevity of the material further underscores its sustainability, as its robust nature reduces the need for frequent replacements. In terms of trustworthiness, the global standardization and meticulous quality control processes that govern stainless steel grating production ensure high reliability. Major producers of stainless steel grating adhere to stringent ISO standards, providing assurance of material quality and performance consistency. This level of scrutiny and certification offers peace of mind to project managers and stakeholders who depend on dependable materials for critical projects. However, selecting the right stainless steel grating requires professional expertise. Various grades of stainless steel, such as 304 and 316, have differing suitability depending on the specific environmental conditions and load requirements. Industry experts and engineers can provide valuable guidance in selecting the appropriate material grade and grating configuration to ensure optimal performance and longevity. To sum up, stainless steel grating stands out as a product that offers exceptional experience in terms of operational performance, strong expertise in varying industrial applications, authoritative standards that ensure quality, and a trustworthiness that comes from years of proven reliability. For industries ranging from construction to manufacturing, the choice is clear when it comes to safety, durability, and sustainability—stainless steel grating leads the way.

Adding to its credentials, stainless steel grating is environmentally friendly. Stainless steel is fully recyclable, contributing to sustainable building practices and eco-friendly manufacturing processes. This trait aligns with the growing global emphasis on reducing environmental footprints, making stainless steel grating an ideal choice for green construction projects. The longevity of the material further underscores its sustainability, as its robust nature reduces the need for frequent replacements. In terms of trustworthiness, the global standardization and meticulous quality control processes that govern stainless steel grating production ensure high reliability. Major producers of stainless steel grating adhere to stringent ISO standards, providing assurance of material quality and performance consistency. This level of scrutiny and certification offers peace of mind to project managers and stakeholders who depend on dependable materials for critical projects. However, selecting the right stainless steel grating requires professional expertise. Various grades of stainless steel, such as 304 and 316, have differing suitability depending on the specific environmental conditions and load requirements. Industry experts and engineers can provide valuable guidance in selecting the appropriate material grade and grating configuration to ensure optimal performance and longevity. To sum up, stainless steel grating stands out as a product that offers exceptional experience in terms of operational performance, strong expertise in varying industrial applications, authoritative standards that ensure quality, and a trustworthiness that comes from years of proven reliability. For industries ranging from construction to manufacturing, the choice is clear when it comes to safety, durability, and sustainability—stainless steel grating leads the way.

Next:

Latest news

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025