-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 30, 2025 03:11 Back to list

stainless steel angle factories

Steel angle bars are indispensable components within a plethora of industries around the globe. Known for their versatility and robust nature, they serve as a fundamental material in construction, manufacturing, and many engineering applications. Their distinctive L-shape makes them structurally sound, allowing them to provide critical support and stability in various structural frameworks.

Experts in engineering often highlight the efficiency with which steel angle bars can be implemented within structures. Their lightweight yet sturdy nature ensures ease of transportation and installation, significantly reducing the labor costs associated with construction and manufacturing. Moreover, their availability in various sizes and dimensions caters to specific project requirements, ensuring that every task finds its perfect match in a suitably proportioned steel angle bar. In a world where craftsmanship and authority in the industry dictate the pace of development, steel angle bars stand as a testament to innovation and reliability. The processes involved in producing these bars, such as hot rolling and cutting, are governed by stringent standards, ensuring consistency and quality throughout the supply chain. Manufacturers who adhere to international quality standards, such as ISO, earn a reputable standing in the industry, making them trusted partners for construction firms and industrial designers. Furthermore, the thoughtful, environmentally-conscious efforts being implemented now focus on recycling steel angle bars. Steel is a recyclable resource, and the industry has been making strides in ensuring that waste is minimized, and resources are efficiently used. By repurposing steel angle bars, the environmental footprint of construction projects is reduced, aligning with global sustainability goals. It is this kind of forward-thinking and authoritative approach that continues to instill trust and foster long-term relationships in the market. In conclusion, recognizing the paramount importance of steel angle bars in modern industry cannot be overstated. Their extensive range of applications, coupled with their intrinsic properties, underscores their role as a building block in contemporary society. Professionals and business owners seeking reliable, cost-effective solutions will find that these bars offer unparalleled benefits—grounded in a tradition of expertise, authoritative practice, and a trustworthiness that has stood the test of time.

Experts in engineering often highlight the efficiency with which steel angle bars can be implemented within structures. Their lightweight yet sturdy nature ensures ease of transportation and installation, significantly reducing the labor costs associated with construction and manufacturing. Moreover, their availability in various sizes and dimensions caters to specific project requirements, ensuring that every task finds its perfect match in a suitably proportioned steel angle bar. In a world where craftsmanship and authority in the industry dictate the pace of development, steel angle bars stand as a testament to innovation and reliability. The processes involved in producing these bars, such as hot rolling and cutting, are governed by stringent standards, ensuring consistency and quality throughout the supply chain. Manufacturers who adhere to international quality standards, such as ISO, earn a reputable standing in the industry, making them trusted partners for construction firms and industrial designers. Furthermore, the thoughtful, environmentally-conscious efforts being implemented now focus on recycling steel angle bars. Steel is a recyclable resource, and the industry has been making strides in ensuring that waste is minimized, and resources are efficiently used. By repurposing steel angle bars, the environmental footprint of construction projects is reduced, aligning with global sustainability goals. It is this kind of forward-thinking and authoritative approach that continues to instill trust and foster long-term relationships in the market. In conclusion, recognizing the paramount importance of steel angle bars in modern industry cannot be overstated. Their extensive range of applications, coupled with their intrinsic properties, underscores their role as a building block in contemporary society. Professionals and business owners seeking reliable, cost-effective solutions will find that these bars offer unparalleled benefits—grounded in a tradition of expertise, authoritative practice, and a trustworthiness that has stood the test of time.

Latest news

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

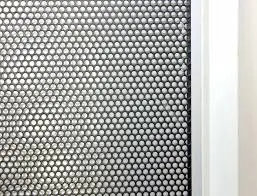

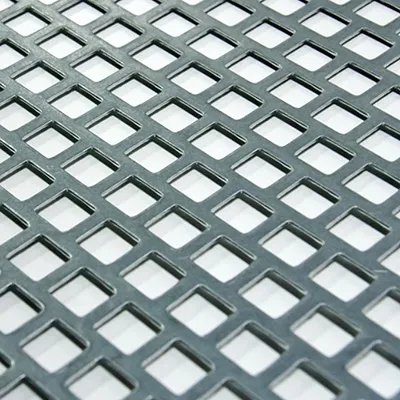

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025