-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лис . 30, 2024 06:42 Back to list

High-Quality Aluminum Perforated Sheets from Leading Manufacturing Facility

Aluminium Perforated Sheet Factory An Overview of Production and Applications

In today's rapidly evolving industrial landscape, aluminium perforated sheets have emerged as a vital material across various sectors. The manufacturing of these sheets primarily takes place in specialized factories equipped with advanced technologies and skilled labor. This article delves into the production process, benefits, and diverse applications of aluminium perforated sheets, shedding light on the significance of the aluminium perforated sheet factory in modern industry.

Production Process

The production of aluminium perforated sheets involves several key stages, beginning with the selection of high-quality raw materials. Aluminium, known for its lightweight and durable properties, is the preferred choice for various applications. The process starts with large aluminium sheets being fed into a perforating machine. This machinery features various tools that create patterns of holes in the metal sheet, which can be customized based on client specifications.

The perforating process can employ different techniques, such as rotary or platen perforation, depending on the desired outcomes. Rotary perforation is often more efficient for larger production runs, while platen perforation allows for greater versatility in hole sizes and patterns. Regardless of the method used, the objective remains the same to create functional, aesthetically appealing sheets that meet the requirements of specific applications.

After perforation, the sheets go through a quality control process to ensure consistency in hole diameter and spacing. This step is crucial, as any defects can significantly impact the sheet's performance and suitability for its intended use. Once approved, the sheets may undergo additional treatments such as anodizing or powder coating to enhance their corrosion resistance and visual appeal.

Benefits of Aluminium Perforated Sheets

The popularity of aluminium perforated sheets can be attributed to several key benefits they offer. Firstly, their lightweight nature makes them easy to handle and install, reducing labor costs and facilitating efficient manufacturing processes. Secondly, aluminium's inherently corrosion-resistant properties ensure that these sheets maintain their integrity even in challenging environments, making them ideal for outdoor applications.

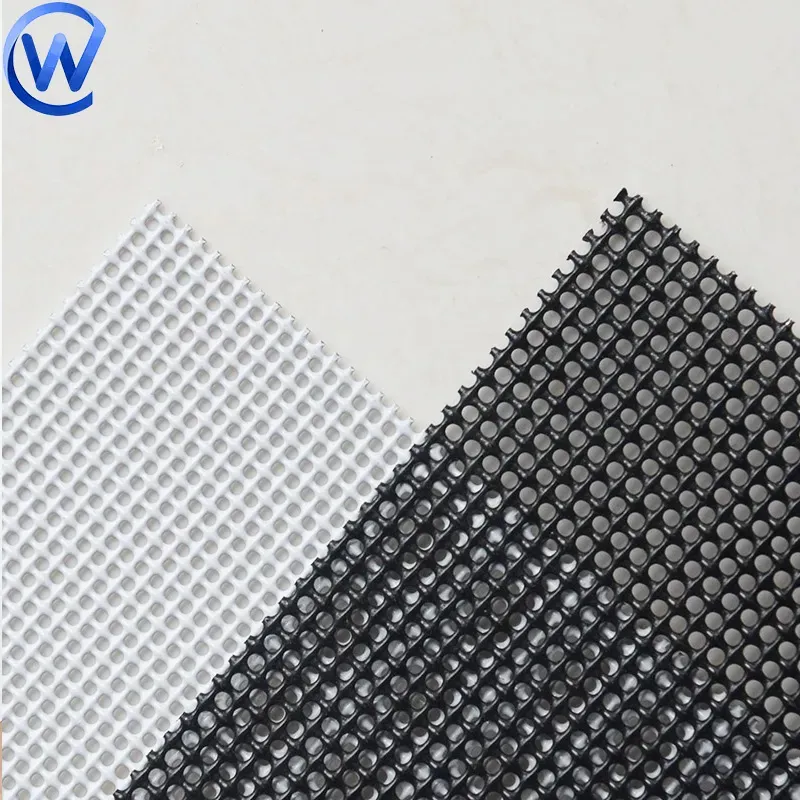

aluminium perforated sheet factory

In addition to their practical advantages, aluminium perforated sheets provide aesthetic versatility. The variety of hole sizes, shapes, and arrangements available allows architects and designers to create visually striking installations. Whether used in ceilings, facades, or decorative partitions, perforated sheets can enhance the overall design of a space while providing functional benefits such as sound absorption and light diffusion.

Applications Across Industries

Aluminium perforated sheets have a wide range of applications spanning various industries. In the construction sector, they are commonly used for cladding and facades, combining durability with aesthetic appeal. Architects appreciate their flexibility in design, allowing for innovative building exteriors that stand out while ensuring structural integrity.

In the automotive industry, perforated aluminium sheets are utilized for components such as grilles and interior panels. Their lightweight nature contributes to overall fuel efficiency, while the ability to customize designs allows manufacturers to create stylish and functional vehicle parts. Similarly, in the aerospace industry, these sheets are applied in various components, contributing to aircraft's weight reduction and efficiency.

Moreover, aluminium perforated sheets find their way into the realms of architecture and interior design. Whether used in office partitions, acoustic panels, or decorative elements, their unique patterns and textures can significantly enhance the aesthetics of a space. Additionally, they are employed in industrial settings for safety barriers, screens, and ventilation covers.

Conclusion

The aluminium perforated sheet factory plays an essential role in modern manufacturing, providing a crucial material that meets the demands of various industries. With an efficient production process, numerous benefits, and wide-ranging applications, aluminium perforated sheets continue to gain traction as a preferred choice for architects, engineers, and manufacturers alike. As industries evolve and innovate, the importance of aluminium perforated sheets—and the factories that produce them—will undoubtedly grow, paving the way for new possibilities in design and functionality.

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025