-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лют . 10, 2025 09:47 Back to list

custom wire mesh

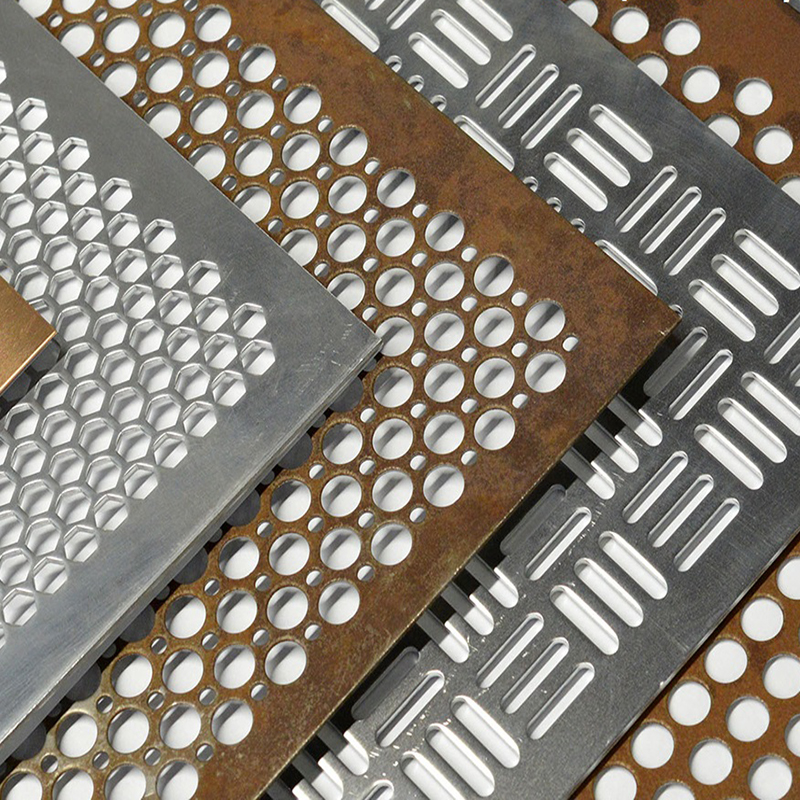

In the realm of architectural and industrial innovation, custom wire mesh stands as a versatile material, integral to various applications ranging from construction reinforcements to artistic installations. It merges functionality with design, offering an unmatched combination of strength, durability, and aesthetic appeal. As industries evolve, the demand for customized solutions tailored to specific needs has prompted an upsurge in the use of wire mesh, a product gaining authority in sectors like construction, agriculture, and manufacturing.

The credibility of custom wire mesh solutions is amplified by expert testimonials and case studies that detail successful user experiences across various sectors. For example, leading aerospace entities employ custom wire mesh to meet stringent parameters, benefitting from its lightweight yet durable nature to protect sensitive instrumentation. The transparency and expertise demonstrated in these collaborations reinforce the industry’s trust in custom wire meshes. Furthermore, when procuring custom wire mesh, partnering with certified manufacturers is crucial. These producers ensure that each mesh product not only meets the bespoke needs of a project but also adheres to environmental standards. Utilizing advanced technologies like laser cutting and CNC machining, they achieve unparalleled precision, which translates into superior product performance. The journey of custom wire mesh from design to deployment reflects a deep-seated expertise that is validated through accredited testing and certification. This aligns with the core SEO principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T), ensuring that content surrounding custom wire mesh not only boosts search visibility but also reinforces consumer confidence. The evolving landscape of custom wire mesh is a testament to its crucial role in modern industrial and architectural applications. By understanding the intricacies of its customization options and recognizing its proven benefits across various sectors, stakeholders can make informed decisions that enhance project outcomes. As a beacon of reliability and innovation, custom wire mesh continues to set benchmarks for product quality and application diversity.

The credibility of custom wire mesh solutions is amplified by expert testimonials and case studies that detail successful user experiences across various sectors. For example, leading aerospace entities employ custom wire mesh to meet stringent parameters, benefitting from its lightweight yet durable nature to protect sensitive instrumentation. The transparency and expertise demonstrated in these collaborations reinforce the industry’s trust in custom wire meshes. Furthermore, when procuring custom wire mesh, partnering with certified manufacturers is crucial. These producers ensure that each mesh product not only meets the bespoke needs of a project but also adheres to environmental standards. Utilizing advanced technologies like laser cutting and CNC machining, they achieve unparalleled precision, which translates into superior product performance. The journey of custom wire mesh from design to deployment reflects a deep-seated expertise that is validated through accredited testing and certification. This aligns with the core SEO principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T), ensuring that content surrounding custom wire mesh not only boosts search visibility but also reinforces consumer confidence. The evolving landscape of custom wire mesh is a testament to its crucial role in modern industrial and architectural applications. By understanding the intricacies of its customization options and recognizing its proven benefits across various sectors, stakeholders can make informed decisions that enhance project outcomes. As a beacon of reliability and innovation, custom wire mesh continues to set benchmarks for product quality and application diversity.

Latest news

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025