-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 10, 2024 04:26 Back to list

Top Chicken Wire Mesh Suppliers for Your Fencing and Gardening Needs

The Role of Chicken Wire Mesh Manufacturers in Modern Agriculture

In the evolving world of agriculture, one cannot overlook the significance of chicken wire mesh. This versatile material, often used for fencing, gardening, and construction purposes, has become essential for poultry keepers, landscapers, and even DIY enthusiasts. Behind the production of this indispensable resource are the chicken wire mesh manufacturers, whose role is critical in ensuring quality and availability.

Understanding Chicken Wire Mesh

Chicken wire mesh, also known as poultry netting, is traditionally made from thin, high-gauge wire that is twisted to form a grid of hexagonal holes. It is lightweight yet strong enough to keep chickens and other small animals contained while allowing for ventilation and visibility. Initially designed for poultry farming, its applications have expanded to include garden fencing, rabbit enclosures, and even home decor projects. This expansion has prompted an increase in demand, underscoring the importance of reliable manufacturers in meeting market needs.

The Manufacturing Process

Chicken wire mesh manufacturing involves several stages, each crucial for producing a durable product. The process typically begins with the selection of materials. High-quality steel wire is fundamental to producing chicken wire that can withstand harsh outdoor conditions. Manufacturers must ensure that the wire is treated for rust resistance, especially if the mesh will be exposed to moisture and varying weather conditions.

Once the material is selected, the wire is drawn through a series of dies to achieve the desired gauge and length. The next step involves weaving the wire into the characteristic hexagonal shape. This weaving process can be done manually or with the assistance of machines, depending on the scale of production. After weaving, the final product is often coated with a protective layer, such as galvanized coating, to enhance durability and longevity.

Quality Control and Standards

Quality is paramount in the manufacturing of chicken wire mesh. Reputable manufacturers adhere to stringent quality control standards to ensure that the mesh is consistent in strength and finish. Regular testing for tensile strength, corrosion resistance, and flexibility is common practice, ensuring that the final product can withstand the rigors of farming and outdoor use.

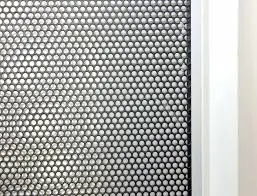

chicken wire mesh manufacturers

Additionally, many manufacturers comply with international standards and certifications, which not only boosts consumer confidence but also enhances their marketability. By investing in quality control, manufacturers can establish a solid reputation, differentiate themselves from competitors, and meet the evolving demands of agricultural practices.

Innovation in Manufacturing

As technology progresses, chicken wire mesh manufacturers are also embracing innovations that enhance production efficiency and product offerings. Advanced manufacturing techniques, such as automated weaving and enhanced coating processes, reduce production time and costs while improving product quality.

Furthermore, some manufacturers are exploring sustainable practices by using recycled materials or producing eco-friendly coatings. As the agriculture industry increasingly seeks sustainable and environmentally friendly products, manufacturers who adapt to these trends will be better positioned in the market.

Market Demand and Future Trends

The demand for chicken wire mesh continues to rise, driven by the growing popularity of backyard poultry farming, gardening, and home improvement projects. As consumers become more conscious of food sources and sustainability, the interest in raising chickens and growing home gardens is expected to persist, fostering ongoing demand for quality chicken wire mesh.

Moreover, the integration of smart technology in agriculture presents new opportunities. Manufacturers that can innovate and incorporate technology into their products—such as mesh with embedded sensors for animal tracking—may well lead the market in the coming years.

Conclusion

In conclusion, chicken wire mesh manufacturers play a pivotal role in modern agriculture. Their commitment to quality, innovation, and sustainability directly impacts the farming community and the broader market. As trends evolve, these manufacturers must continue to adapt and meet the needs of consumers, ensuring the availability of high-quality chicken wire mesh for generations to come. Whether you are a seasoned farmer or a weekend gardener, understanding the value of these manufacturers is essential in making informed choices about the materials we use in our agricultural endeavors.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025