-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ott . 22, 2024 08:01 Back to list

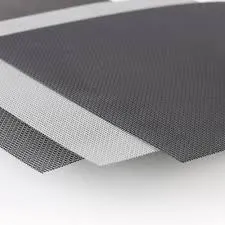

custom galvanized iron wire

Custom Galvanized Iron Wire The Ultimate Solution for Durability and Versatility

Galvanized iron wire has become a staple in numerous industries due to its remarkable durability and resistance to corrosion. This type of wire is coated with a protective zinc layer, which not only enhances its longevity but also makes it ideal for various applications ranging from construction to agriculture. Custom galvanized iron wire takes this versatility a step further, allowing customers to specify dimensions, tensile strength, and coating thickness to suit their specific needs.

Understanding Galvanization

Galvanization is the process of applying a protective zinc coating to iron or steel to prevent rusting. This process primarily involves hot-dip galvanization, where steel components are submerged in molten zinc, creating a thick and durable coating. The result is an oxidation barrier that can withstand harsh environmental conditions, making galvanized iron wire an excellent choice for outdoor applications.

Applications of Custom Galvanized Iron Wire

1. Construction Industry Custom galvanized iron wire is extensively used in the construction sector. It serves multiple purposes, such as tying rebar together, creating cages, and providing structural support. Because it is resistant to rust, it ensures the integrity of structures over time.

2. Agriculture Farmers utilize galvanized iron wire for fencing, supporting plants, and creating trellises. Its durability ensures that it can withstand various weather conditions while effectively containing livestock and protecting crops.

3. Craft and DIY Projects For those in the crafting and DIY community, custom galvanized iron wire is a favorite for making wreaths, sculptures, and other ornamental items. Its malleability and strength make it easy to work with while providing a professional finish.

4. Industrial Use In industrial environments, galvanized iron wire is used for manufacturing various products, including wire mesh, netting, and cages. Its corrosion resistance is particularly beneficial in industries exposed to chemicals and moisture.

custom galvanized iron wire

5. Electrical Applications Copper wire can be expensive for some applications, leading many manufacturers to turn to galvanized iron wire for grounding and electrical installations. Its conductive properties, combined with the protective coating, make it a reliable option for specific electrical needs.

Benefits of Choosing Custom Options

By opting for custom galvanized iron wire, businesses and individuals can ensure that they are getting exactly what they need for their specific applications. Customization allows for

- Perfect Fit Tailoring the wire’s diameter and length to match the requirements of a project ensures that the end product is efficient and effective.

- Enhanced Performance Changes in tensile strength can make the wire suitable for more demanding applications, providing peace of mind.

- Cost Efficiency Custom orders often lead to reduced material waste, as clients can avoid over-ordering or under-sizing their projects.

- Unique Specifications Customization can also involve unique coatings or treatments, allowing the wire to meet industry-specific standards and regulations.

Conclusion

In conclusion, custom galvanized iron wire represents an essential resource across various sectors, providing durability, versatility, and customization. Whether for construction, agriculture, crafts, or industrial purposes, its robust characteristics and tailored options make it an invaluable addition to any project. Emphasizing the importance of quality and specific requirements, businesses and individuals can benefit immensely from choosing custom solutions in their wire needs.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025