-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ago . 09, 2024 22:50 Back to list

Durable Galvanized Welded Wire Mesh Panels for Various Applications and Projects

The Versatility and Benefits of Galvanized Welded Wire Mesh Panels

Galvanized welded wire mesh panels have become a staple in various industries and applications due to their durability, strength, and versatility. These panels are created by welding wire strands together and then coating them with a layer of galvanized zinc, which provides excellent corrosion resistance. This article will explore the characteristics, uses, and advantages of galvanized welded wire mesh panels, highlighting why they are a preferred choice for many projects.

Characteristics of Galvanized Welded Wire Mesh Panels

The production process of galvanized welded wire mesh involves precision welding of high-quality wire to form a grid-like pattern. The wires are typically available in various diameters, which can be selected based on the specific needs of a project. The galvanization process is particularly crucial as it significantly enhances the lifespan of the mesh; it protects the wire from rust and corrosion, making it suitable for outdoor applications and environments that experience high humidity.

Galvanized welded wire mesh panels can come in various thicknesses and mesh sizes, making them customizable for numerous applications. The rigidity of these panels allows them to maintain their shape over time, which is vital in structural applications. Additionally, the smooth surface of the galvanized coating ensures that the panels are easy to clean and maintain.

Applications of Galvanized Welded Wire Mesh Panels

The applications of galvanized welded wire mesh panels are vast and can be seen in various sectors

. In the construction industry, these panels are widely used for reinforcing concrete structures, providing additional strength and stability. Furthermore, they are employed in fencing solutions, where they offer a secure barrier without sacrificing visibility.In agriculture, galvanized welded wire mesh panels serve multiple purposes, such as constructing animal enclosures or supports for climbing plants. Their durability makes them an ideal choice for environments subjected to harsh weather conditions, ensuring that they last for years without deteriorating.

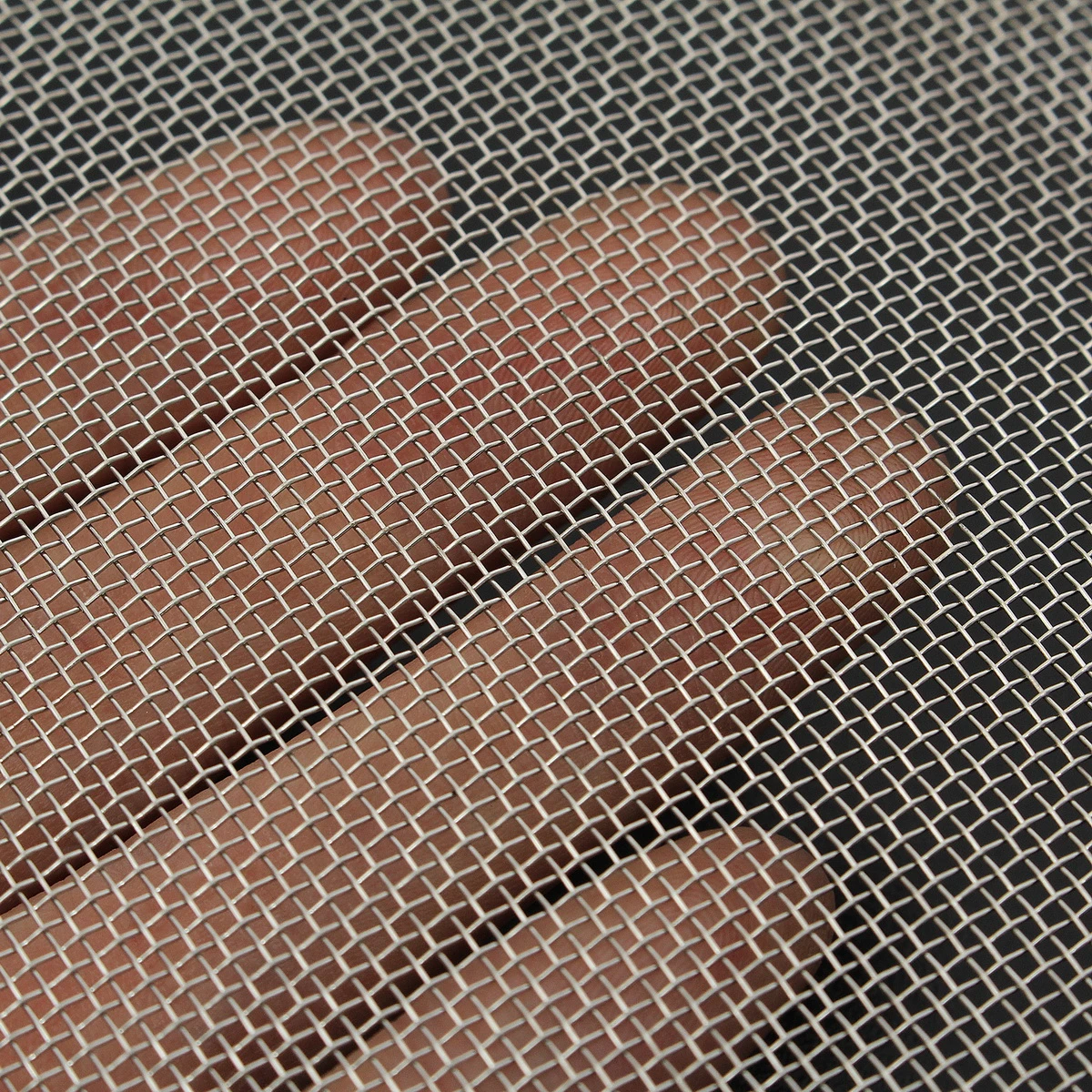

galvanized welded wire mesh panels

In the industrial sector, these panels are utilized for shelving, storage, and guarding machinery, ensuring safety and organization within warehouses. The panels can also be used in the creation of partitions in offices or workshops, allowing for functional and aesthetically pleasing workspace designs.

Advantages of Using Galvanized Welded Wire Mesh Panels

One of the primary advantages of galvanized welded wire mesh panels is their long lifespan. The galvanized coating offers exceptional protection against rust, making them ideal for outdoor settings where exposure to the elements can lead to rapid deterioration. This longevity translates to cost savings for businesses and individuals alike, as they won’t need to replace the panels frequently.

Additionally, the ease of installation is another significant benefit. Galvanized welded wire mesh panels are lightweight and easy to transport, simplifying installation processes. Their versatility allows them to be cut and shaped to fit various applications, which is especially valuable in custom projects.

Another noteworthy advantage is their environmental impact. As galvanized welded wire mesh panels are made from recyclable materials, they contribute to sustainable building practices. By choosing these panels, you are making a conscious choice towards reducing waste and promoting eco-friendly solutions.

Conclusion

In conclusion, galvanized welded wire mesh panels offer a multitude of benefits across a variety of applications. Their strength, durability, and corrosion resistance make them an optimal choice for construction, agriculture, and industrial projects. As industries continue to innovate and seek efficient solutions, the role of galvanized welded wire mesh panels is likely to expand, solidifying their place as a fundamental component in structural integrity and safety. Whether for building, fencing, or agricultural use, these panels provide a reliable and sustainable option for modern needs.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025