-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ott . 07, 2024 13:02 Back to list

galvanized welded wire mesh panels factories

The Rise of Galvanized Welded Wire Mesh Panels Factories

In recent years, the construction and landscaping industries have witnessed a surge in demand for galvanized welded wire mesh panels. These versatile and robust products have become indispensable, thanks to their strength, durability, and corrosion resistance. Factories specializing in the production of galvanized welded wire mesh panels have emerged as key players in meeting this growing demand.

Understanding Galvanized Welded Wire Mesh Panels

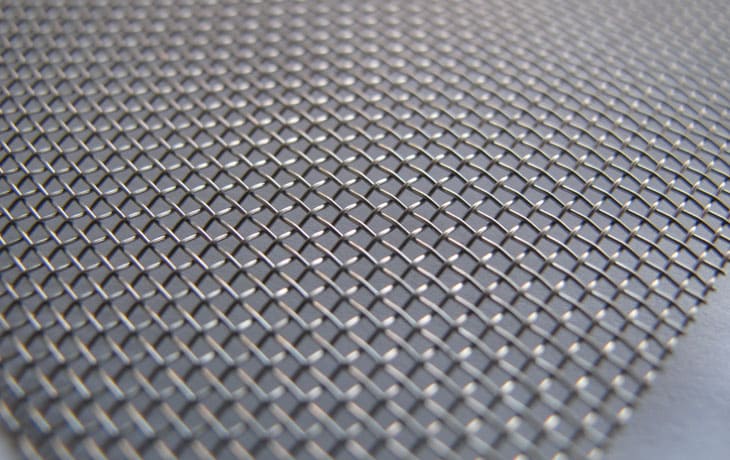

Galvanized welded wire mesh panels are made by welding together steel wires at their intersections and then coating them with a layer of zinc to protect against rust and corrosion. This galvanization process can be achieved either through hot-dip galvanization, which offers superior protection, or electro-galvanization, which provides a smoother finish but less durability. The result is a strong, long-lasting mesh product suitable for various applications, including fencing, agriculture, and construction.

The Manufacturing Process

The production of galvanized welded wire mesh panels involves several critical steps. Initially, steel wires are drawn into specific diameters and cut to the required lengths. These wires are then arranged into a grid pattern and welded at each intersection using advanced machinery to ensure uniform strength throughout the panel. After welding, the panels are subjected to the galvanization process to enhance their resistance to environmental elements.

Factories are increasingly adopting automated systems to improve efficiency and ensure consistent quality across their product lines. This shift towards automation not only speeds up production but also reduces labor costs, making the factories more competitive in the market.

Demand in Various Industries

The demand for galvanized welded wire mesh panels spans multiple sectors

. In agriculture, these panels are often used in fencing livestock and securing crops from wildlife. In construction, they are employed as reinforcement in concrete structures and as a base for plaster, offering enhanced stability and strength.Moreover, the landscaping industry utilizes these panels for decorative purposes and as tree guards. Their adaptability allows them to meet the needs of various applications, further driving their popularity.

galvanized welded wire mesh panels factories

Sustainability and Environmental Considerations

As global awareness of environmental issues continues to rise, factories producing galvanized welded wire mesh panels are increasingly focusing on sustainable practices. Many manufacturers are implementing energy-efficient technologies and sourcing raw materials from environmentally responsible suppliers. Furthermore, galvanized wire mesh is recyclable, aligning with the principles of a circular economy and minimizing waste.

Innovation and Customization

Innovation plays a crucial role in the evolution of galvanized welded wire mesh panels. Factories are continually exploring new designs and manufacturing techniques to cater to customer needs. Customization has become a significant trend, with clients often requesting panels of specific sizes, wire gauges, and mesh patterns to suit their projects. This level of flexibility allows manufacturers to cater to niche markets and provide tailored solutions that meet unique customer specifications.

Future Prospects

The future of galvanized welded wire mesh panel factories looks bright. As urbanization continues to expand across the globe, the need for reliable building materials will only increase. Additionally, ongoing developments in technology and manufacturing processes promise to enhance production capacities and product quality.

Investment in research and development is likely to yield innovative mesh products that can meet even more demanding applications. The emphasis on sustainability will also drive factories to further refine their processes, minimizing their environmental impact while maximizing efficiency.

Conclusion

Galvanized welded wire mesh panels represent a vital component of modern infrastructure and landscaping solutions. As specialized factories continue to meet the growing demand through innovation and sustainability practices, these products will undoubtedly play an even more significant role in shaping our built environment. The future holds great potential for manufacturers, as they strive to balance quality, efficiency, and environmental responsibility while catering to an increasingly diverse array of applications.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025