-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Lug . 28, 2024 15:53 Back to list

High-Quality Custom Electro Galvanized Wire for Durable and Corrosion-Resistant Applications in Various Industries

Custom Electro Galvanized Wire An Overview

Electro galvanized wire has emerged as a vital component in various industrial applications due to its enhanced corrosion resistance and adaptability. This type of wire is produced using an electroplating process that envelops the steel wire in a thin layer of zinc, which serves as a protective barrier against harsh environmental conditions. The custom aspect of this product allows for specific adaptations to meet the diverse needs of various industries, making it a versatile choice for manufacturers and construction firms alike.

What is Electro Galvanized Wire?

Electro galvanized wire is made from high-quality steel and is coated with zinc through a process involving an electric current. This method ensures an even and uniform coating, which is crucial for effective corrosion resistance. The wire is typically lighter in weight than hot-dipped galvanized wire, making it easier to handle and install. This wire can be produced in multiple thicknesses and configurations, catering to the particular requirements of end-users.

Benefits of Customization

1. Tailored Solutions One of the most significant advantages of custom electro galvanized wire is the ability to tailor specifications according to client requirements. Industries such as construction, agriculture, and manufacturing often have unique demands that standard products cannot fulfill. Custom solutions can include varying diameters, tensile strengths, and a range of finishes.

2. Enhanced Performance Customized electro galvanized wire can be engineered for specific performance characteristics, making it suitable for various applications from fencing to wire harnessing. For instance, it can be optimized for flexibility or rigidity, ensuring it meets the performance standards required by different projects.

3. Cost-Effectiveness Custom solutions can also lead to cost savings in the long run. By opting for wire that meets specific project demands, companies can avoid wastage associated with using over-specification products. Custom production also allows for better inventory management, reducing storage costs and streamlining production processes.

custom electro galvanized wire

Applications of Electro Galvanized Wire

The applications of custom electro galvanized wire are extensive

- Construction and Infrastructure In the construction sector, electro galvanized wire is commonly used for reinforcement in concrete structures, fencing, and temporary supports. Its resistance to rust and degradation makes it an ideal choice for outdoor projects.

- Agriculture Farmers utilize electro galvanized wire for fencing livestock, trellising plants, and creating protective barriers for crops. The durability of this wire minimizes maintenance efforts and increases its lifespan in agricultural environments.

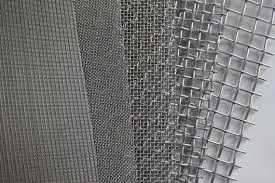

- Manufacturing In manufacturing processes, custom electro galvanized wire is employed in the production of various metal products and components. Its adaptability lends itself well to the manufacturing of wire mesh, cable assemblies, and automotive parts.

Conclusion

Custom electro galvanized wire represents an essential product in today's industrial landscape. Its unique properties and customizable nature provide solutions that meet the diverse requirements of various sectors. As businesses continue to seek materials that offer durability, flexibility, and cost-efficiency, the demand for custom electro galvanized wire will likely grow. By leveraging its advantages, companies can ensure that they are well-equipped to handle the challenges of modern production and construction while maintaining high standards of quality and performance.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025