-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 28, 2025 01:39 Back to list

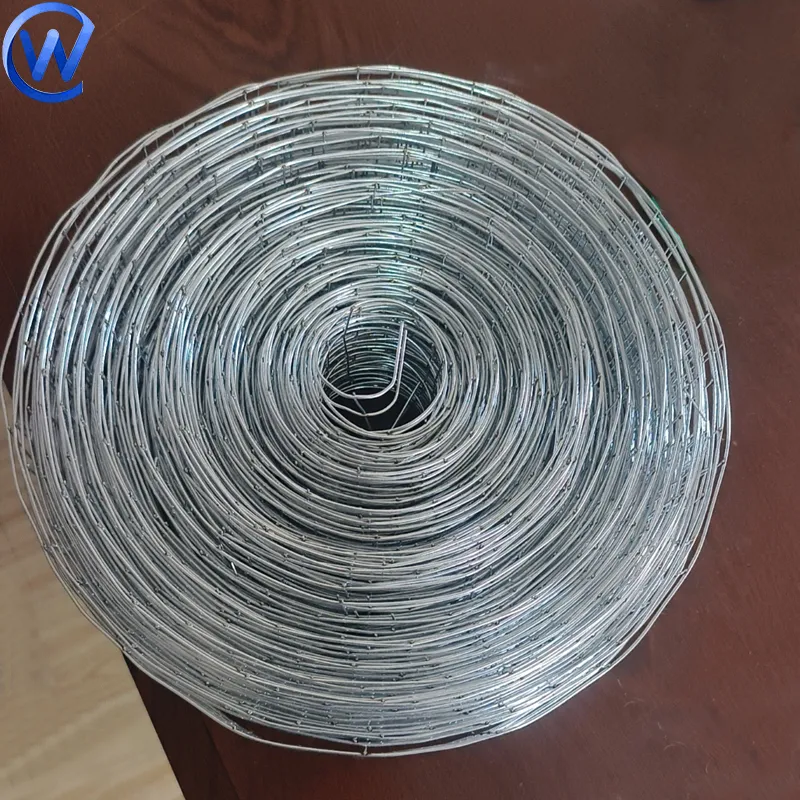

ladder brick mesh

Navigating the complex landscape of construction materials involves understanding the intricate relationship between various components. One such trio that has gained significant attention in recent years is ladder brick mesh. This unique combination not only enhances structural integrity but also optimizes project efficiency.

The authoritativeness of ladder brick mesh is validated by its widespread adoption in seismic zones where building codes demand higher resilience against earthquakes. Building authorities and construction regulatory bodies endorse it for its capacity to maintain structural cohesion even under intense seismic activity. This backing by institutional bodies not only highlights the product's superiority but also boosts confidence among builders and developers seeking reliable construction solutions. Trustworthiness associated with ladder brick mesh can be attributed to its track record in the field. Companies manufacturing this product often subject it to rigorous quality control standards and testing processes. These tests simulate various environmental and man-made stress conditions to ensure that the mesh meets the necessary safety and performance specifications. Many construction firms highlight the transparency of these processes as a key factor for trusting the material in high-stakes projects. For project managers and engineers aiming to increase efficiency without compromising on safety, ladder brick mesh presents a compelling case. Its ease of integration into existing construction workflows minimizes labor requirements and expedites project timelines. By choosing such innovative materials, projects not only adhere to modern architectural standards but also exhibit forward-thinking in adopting materials that guarantee durability and resilience. In the competitive landscape of construction, staying ahead requires a dual focus on both innovation and reliability. Ladder brick mesh embodies this balance, providing a structural advantage that is both technically sound and practically advantageous. As the construction industry continues to embrace advanced materials, ladder brick mesh stands out as a hallmark of modern engineering ingenuity and a testament to the potential of combining traditional practices with contemporary advancements.

The authoritativeness of ladder brick mesh is validated by its widespread adoption in seismic zones where building codes demand higher resilience against earthquakes. Building authorities and construction regulatory bodies endorse it for its capacity to maintain structural cohesion even under intense seismic activity. This backing by institutional bodies not only highlights the product's superiority but also boosts confidence among builders and developers seeking reliable construction solutions. Trustworthiness associated with ladder brick mesh can be attributed to its track record in the field. Companies manufacturing this product often subject it to rigorous quality control standards and testing processes. These tests simulate various environmental and man-made stress conditions to ensure that the mesh meets the necessary safety and performance specifications. Many construction firms highlight the transparency of these processes as a key factor for trusting the material in high-stakes projects. For project managers and engineers aiming to increase efficiency without compromising on safety, ladder brick mesh presents a compelling case. Its ease of integration into existing construction workflows minimizes labor requirements and expedites project timelines. By choosing such innovative materials, projects not only adhere to modern architectural standards but also exhibit forward-thinking in adopting materials that guarantee durability and resilience. In the competitive landscape of construction, staying ahead requires a dual focus on both innovation and reliability. Ladder brick mesh embodies this balance, providing a structural advantage that is both technically sound and practically advantageous. As the construction industry continues to embrace advanced materials, ladder brick mesh stands out as a hallmark of modern engineering ingenuity and a testament to the potential of combining traditional practices with contemporary advancements.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025