-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 14, 2025 10:49 Back to list

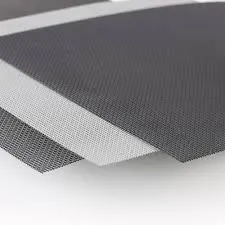

stainless steel wire mesh

Concrete reinforcement steel wire mesh plays an indispensable role in the construction industry. Its utilization in modern infrastructure is a testament to its versatility and reliability, providing not only structural integrity but also a substantial boost in longevity to concrete elements. As someone deeply entrenched in the construction field, I can attest to the transformative benefits that high-quality steel wire mesh delivers to projects of varying scales.

For those interested in this field or implementing these practices in their projects, detailed knowledge about mesh specifications such as wire gauge, spacing, and coating types is imperative. These factors influence the mesh’s resistance to environmental factors like moisture and corrosion, ultimately affecting the structural integrity of the finished product. Suppliers of concrete reinforcement steel wire mesh also play a substantial role in the trustworthiness of this material. Partnering with reputable manufacturers ensures access to high-grade products with guarantees that back up the reliability claims. The sourcing process should be meticulous, prioritizing firms with a history of satisfied clients and positive testimonials. As we push the boundaries of what is possible in infrastructure development, Sustainability emerges as a focal point. Steel wire mesh can be recycled at the end of its lifecycle. This capability aligns with the global shift towards greener construction practices, presenting an opportunity to rebuild not only stronger but also smarter. Crafting durable, long-lasting structures begins with informed material choices. Steel wire mesh offers a dynamic solution for enhancing concrete resilience. It embodies a blend of practicality and innovation, grounded in the principles of modern engineering and strengthened by decades of development. Investing in this versatile material is a step forward in ensuring that our buildings are equipped to withstand the tests of time and nature alike.

For those interested in this field or implementing these practices in their projects, detailed knowledge about mesh specifications such as wire gauge, spacing, and coating types is imperative. These factors influence the mesh’s resistance to environmental factors like moisture and corrosion, ultimately affecting the structural integrity of the finished product. Suppliers of concrete reinforcement steel wire mesh also play a substantial role in the trustworthiness of this material. Partnering with reputable manufacturers ensures access to high-grade products with guarantees that back up the reliability claims. The sourcing process should be meticulous, prioritizing firms with a history of satisfied clients and positive testimonials. As we push the boundaries of what is possible in infrastructure development, Sustainability emerges as a focal point. Steel wire mesh can be recycled at the end of its lifecycle. This capability aligns with the global shift towards greener construction practices, presenting an opportunity to rebuild not only stronger but also smarter. Crafting durable, long-lasting structures begins with informed material choices. Steel wire mesh offers a dynamic solution for enhancing concrete resilience. It embodies a blend of practicality and innovation, grounded in the principles of modern engineering and strengthened by decades of development. Investing in this versatile material is a step forward in ensuring that our buildings are equipped to withstand the tests of time and nature alike.

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025