When discussing a project involving access products such as steel grating, you’ll find a number of different terms are used. Our team has prepared the must-know terminology used, from start to finish, from preparing drawings to fabrication, consulting with engineers, drafting, fabricators, and specifiers. For further information and diagrams – please see our Terminology Download page.

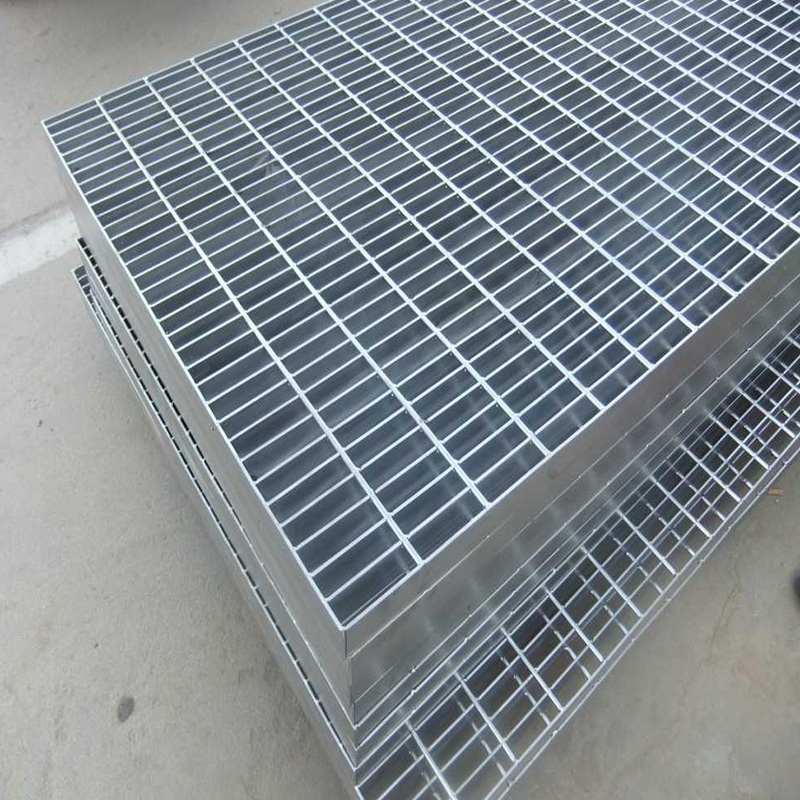

Steel Grating

1. Load Bearing Bar

In steel gratings, the load-bearing bar is the area spanning between the support centres. A load bar is designed to provide high safety and strength and, therefore, are used in industrial and commercial environments such as elevated walkways and flooring solutions. Load bars can also present in other materials, including mild steel, aluminium, and fibreglass.

2. Length (Direction of Span)

Length is the overall dimension of the grating panel that is measured parallel to the load-bearing bars along the direction of the span.

3. Nosing Bar

Nosing bars, also referred to as stair nosing, are attachments to the front edge of the stair tread or top stair landing panels, such as replaceable nosing or plate nosing. These attachments improve safety and provide an anti-slip stair surface.

4. Cross Bar

Crossbars are the connecting bars that extend across the load-bearing bars at right angles to provide lateral support. For Weldlok this is our innovative Forgebar technology. They are usually made from steel strips or rolled bars and are welded, forged, or mechanically locked perpendicular to the load-bearing bar.

5. Width

The width is the overall dimension of the grating panel measured at right angles to the loadbearing bars, the same as the crossbars. Panels are designed at a maximum width and length in line with load bearing requirements.

6. Kick Plate

A kick plate is a large flat bar welded at the sides or ends and around the cut-outs of a grating panel. They can extend 100mm above the walking surface and can close off gaps to prevent items from falling over.

7. Edge Bar

Edge bars are non-load bearing bars that run perpendicular to the load-bearing bars. They provide improved stability and rigidity to the grating panel.

8. Serrations

Serrations are notches made on the top surface of the load-bearing bar as a measure to improve skid resistance and safety. Many Weldlok grating types are available with serrated finishes.

9. Cut-Outs

Cut-outs are an area removed in the grating or flooring to allow any obstruction or materials like columns, pipes, and machinery to pass through them. Weldlok can design and fabricate the exact cut outs required based on area drawings.

10. Nett Area

Nett area is the remaining area in the flooring or grating after deduction of cut-outs from them ([A x B] – [C x D]).