-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th2 . 15, 2025 19:12 Back to list

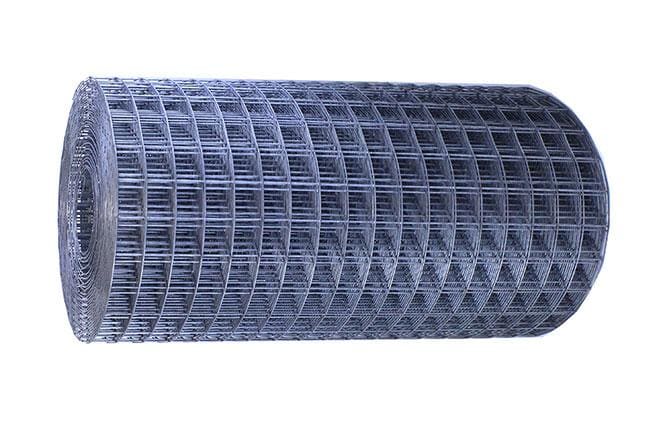

custom iron wire mesh

Crafting a high-quality custom iron wire mesh involves an intricate balance of craftsmanship, innovation, and a keen understanding of diverse industry needs. As a crucial component in various applications ranging from architectural frameworks to industrial sieves, custom iron wire mesh products must meet precise specifications to ensure optimal performance and longevity.

Real-world experiences from industry leaders highlight the transformative impact of custom iron wire mesh on client projects. For instance, construction projects often encounter challenges such as high wind loads or seismic activity. Custom solutions tailored to these specific conditions not only meet but exceed safety standards, mitigating risks and ensuring project stability. Similarly, in the realm of interior design, custom iron wire mesh installations have pushed the boundaries of conventional spaces, offering solutions that enhance both form and function. Furthermore, as the global market increasingly demands sustainable and eco-friendly practices, custom iron wire mesh production is evolving. Manufacturers are innovating with recycled materials and energy-efficient processes, aligning products with sustainability goals without sacrificing quality. This commitment to ecological responsibility is increasingly important as consumers and businesses alike prioritize environmental impact in their purchasing decisions. The future of custom iron wire mesh is bright, with advancements in technology promising further refinements in manufacturing processes and product capabilities. Automated weaving machines and precision cutting tools are poised to revolutionize the industry, offering unprecedented levels of accuracy and efficiency. However, the timeless value of skilled craftsmen who understand the nuanced art of wire mesh fabrication remains indispensable. In conclusion, custom iron wire mesh is a multifaceted product integral to numerous industries. Its success in application hinges on the confluence of experience, expertise, authority, and trustworthiness. By understanding and leveraging these elements, manufacturers can not only meet existing market demands but also innovate and lead, setting new benchmarks in quality and performance. As industries continue to evolve, the adaptability, strength, and aesthetic potential of custom iron wire mesh ensure its lasting relevance and utility in diverse settings.

Real-world experiences from industry leaders highlight the transformative impact of custom iron wire mesh on client projects. For instance, construction projects often encounter challenges such as high wind loads or seismic activity. Custom solutions tailored to these specific conditions not only meet but exceed safety standards, mitigating risks and ensuring project stability. Similarly, in the realm of interior design, custom iron wire mesh installations have pushed the boundaries of conventional spaces, offering solutions that enhance both form and function. Furthermore, as the global market increasingly demands sustainable and eco-friendly practices, custom iron wire mesh production is evolving. Manufacturers are innovating with recycled materials and energy-efficient processes, aligning products with sustainability goals without sacrificing quality. This commitment to ecological responsibility is increasingly important as consumers and businesses alike prioritize environmental impact in their purchasing decisions. The future of custom iron wire mesh is bright, with advancements in technology promising further refinements in manufacturing processes and product capabilities. Automated weaving machines and precision cutting tools are poised to revolutionize the industry, offering unprecedented levels of accuracy and efficiency. However, the timeless value of skilled craftsmen who understand the nuanced art of wire mesh fabrication remains indispensable. In conclusion, custom iron wire mesh is a multifaceted product integral to numerous industries. Its success in application hinges on the confluence of experience, expertise, authority, and trustworthiness. By understanding and leveraging these elements, manufacturers can not only meet existing market demands but also innovate and lead, setting new benchmarks in quality and performance. As industries continue to evolve, the adaptability, strength, and aesthetic potential of custom iron wire mesh ensure its lasting relevance and utility in diverse settings.

Latest news

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025